Lithium battery aluminum foil is becoming increasingly popular in the battery industry due to its ability to provide superior performance and longer service life. The foil is used to wrap cells and help with heat dissipation and electrical insulation. This material is also highly resistant to corrosion and oxidation, which makes it an ideal choice for high-performance batteries.

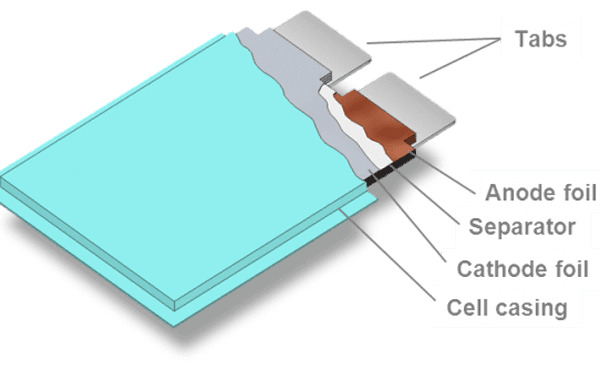

Lithium Battery Aluminum Foil is a specialized type of aluminum foil specifically designed for use in lithium-ion batteries, which are widely used in various electronic devices, electric vehicles, and renewable energy systems. It serves as an essential component within the battery structure, providing multiple functions and contributing to its overall performance and safety.

aluminum foil for battery

Lithium Battery Aluminum Foil is typically made from high-purity aluminum with precise specifications to meet the requirements of battery manufacturers.

Lithium Battery Aluminum Foil is typically made from aluminum alloys that are specifically formulated to meet the requirements of lithium-ion batteries. These alloys possess specific characteristics that make them well-suited for use in battery applications. While the exact alloy composition may vary among manufacturers, here are some commonly used alloys for Lithium Battery Aluminum Foil:

Aluminum Alloy 1235: This alloy is widely used in Lithium Battery Aluminum Foil production. It is a high-purity aluminum alloy with excellent electrical conductivity and good formability. 1235 aluminum foil exhibits high thermal resistance and is suitable for applications requiring lightweight and flexible foils.

1235 aluminum foil for battery

Aluminum Alloy 1060: Another commonly used alloy, 1060 offers good electrical conductivity, high purity, and excellent corrosion resistance. It is known for its high ductility and ease of processing, making it suitable for various Lithium Battery Aluminum Foil applications.

Aluminum Alloy 8021: Alloy 8021 is a high-strength aluminum alloy that provides improved mechanical properties compared to alloys like 1235 and 1060. It offers excellent barrier properties against moisture, gases, and light, making it suitable for applications where enhanced protection is required.

Aluminum Alloy 8079: Alloy 8079 is a high-strength aluminum alloy with enhanced tensile strength and elongation properties. It exhibits excellent barrier performance against moisture, oxygen, and other contaminants. Alloy 8079 is often used for Lithium Battery Aluminum Foil in applications where high barrier properties and mechanical strength are crucial.

Lithium Battery Aluminum Foil

These alloys are chosen aluminum foil for battery production due to their specific combination of properties, including electrical conductivity, thermal resistance, flexibility, formability, and barrier performance. The selection of the alloy depends on factors such as battery requirements, manufacturing processes, and desired performance characteristics.

| Use | Battery soft package | Lithium battery |

| Typical alloy | 8021, 8079 | 1050, 1060, 1070, 1100, 1235 |

| Temper | O, H*4, H*8 | |

| Thickness (mm) | 0.015-0.2 | |

| Width (mm) | 100-1600 | |

| Length (mm) | Coil | |

| Treatment | mill finish | |

| Standard | ISO SGS ASTM ENAW | |

| Price terms | LC/TT/DA/DP | |

| Packaging | Standard seaworthy export packaging. Wooden pallets with plastics protection for the coil and sheet. | |

| Standard thickness/mm | 0.0060 | 0.0070 | 0.0080 | 0.0090 | 0.010 | 0.11 | 0.16 |

| Maximum resistance/(Ω.m) | 0.55 | 0.51 | 0.43 | 0.36 | 0.32 | 0.28 | 0.25 |

By utilizing Lithium Battery Aluminum Foil, battery manufacturers can enhance the overall performance, reliability, and safety of lithium-ion batteries. Its properties help optimize the battery’s energy storage capabilities, improve charge/discharge efficiency, and minimize the risk of thermal runaway or other safety hazards.

Where is the aluminum foil used in the lithium battery

aluminum foil packaged battery

First, the surface of the aluminum foil is uniform, clean and flat, without obvious roller marks, pits, pinholes and corrosion marks;

Second, there are no rolling defects such as creases, mottling and bright lines on the surface of the aluminum foil;

Third, there is no color difference on the surface of aluminum foil;

Tourth, surface is free of oil, no serious oil smell, and no oil spots visible to the naked eye;

Fifth, surface tension, the dyne pen test is not less than 32 dyne;

Our 3003 Aluminum foil products have been exported to Australia, Morocco, Syria, Kuwait, Turkey, Saudi Arabia, UAE, Iraq, Jordan, Germany, Poland, Spain, Brazil, etc. We sincerely welcome you to visit our factory.

8021 aluminium foil is a common alloy in 8000 series aluminum alloys. Common aluminum foils in 8000 series aluminum alloys include 8011 Aluminum Foil and 8079.

6061 aluminum sheet is an al-si-mg alloy that has been strengthened by precipitation hardening. 6061 aluminum has a high strength-to-weight ratio, above-average corrosion resistance, good machinability, and is well suited for welding.

Diamond plate aluminum sheets 4x8 is available in 6061-T6 and 3003-H14 sizes. they have higher strength, wear resistance, load-bearing, machinability, corrosion resistance, etc. Therefore, popular in construction, manufacturing, vehicles, ships and various fields.

Huawei Aluminum is a high-quality 8079 aluminum foil manufacturer. It has multiple advantages in the production of 8079 aluminum foil. Its aluminum foil products are deeply loved by customers at home and abroad.

3005 aluminum plate belongs to Al-Mn alloy. The strength of 3005 aluminum plate is about 20% higher than that of 3003 aluminum plate, and its corrosion resistance is also better.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip