Hliníková fólie klimatizace je materiál používaný k výrobě výměníků tepla klimatizace. Jeho hlavní vlastnosti jsou lehké a tenké, dobrá tepelná vodivost, a odolnost proti korozi.

Hliníková fólie klimatizace je materiál používaný k výrobě výměníků tepla klimatizace. Jeho hlavní vlastnosti jsou lehké a tenké, dobrá tepelná vodivost, a odolnost proti korozi. Kvůli své dobré tepelné vodivosti, it can make the air flow fully in the heat exchanger, so as to achieve better cooling or heating effect.

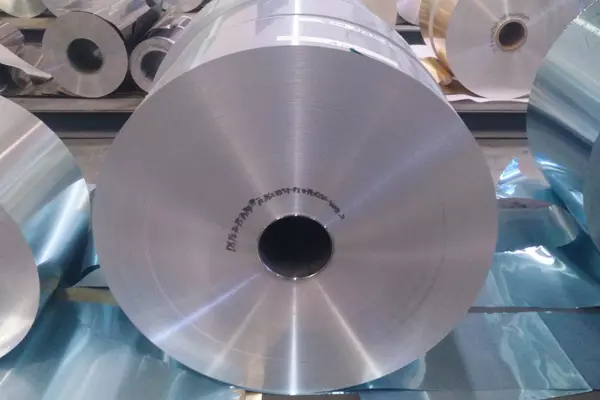

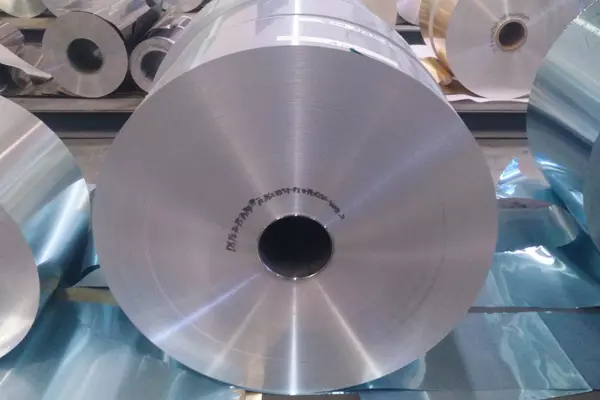

Hliníková fólie klimatizace

Podle tl, it can be divided into thin plate and medium plate. The GB/T3880-2006 standard stipulates that the thickness below 0.2 mm is called aluminum foil.

Air conditioners are gradually developing in the direction of miniaturization, high efficiency and long life. The air-conditioning heat exchange fins are also correspondingly developed in the direction of ultra-thin and high-strength. In the 1980s, the thickness of the heat exchanger fins was 0.15-0.2mm, but now the thickness is only between 0.09 and 0.15mm.

The alloy grades of aluminum foil for heat exchange fins mainly include 1100, 1200, 8011, 8021, 8079, atd. From the point of view of use, air conditioners have no strict requirements on the chemical composition of aluminum heat exchanger fins. Which alloy to choose mainly depends on the final mechanical properties that the material can achieve. Například, it is easier to roll the 1100 aluminum alloy with higher purity, but it is more difficult for the 8011 slitina.

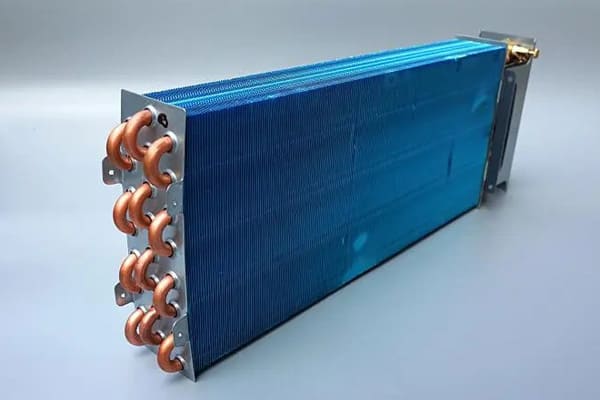

Aluminum foil plays a very important role in air conditioning refrigeration. It is used in evaporators and condensers of air conditioners. Konkrétně, aluminum foil is used to make the shells and internal piping of evaporators and condensers. Aluminum foil is a very good heat-conducting material, which can help the refrigerant absorb and release heat quickly.

Aluminum foil also has good corrosion resistance. During the cycle of the refrigerant, the refrigerant will come into contact with the aluminum foil. If non-corrosion-resistant materials are used, the refrigerant will corrode the pipes and cause leakage, causing the air conditioner to lose its cooling effect. Aluminum foil has good corrosion resistance, which can effectively prevent this from happening.

Navíc, aluminum foil also has good strength and toughness. When making evaporators and condensers, aluminum foil needs to be bent into different shapes, so it needs to have certain toughness and strength.

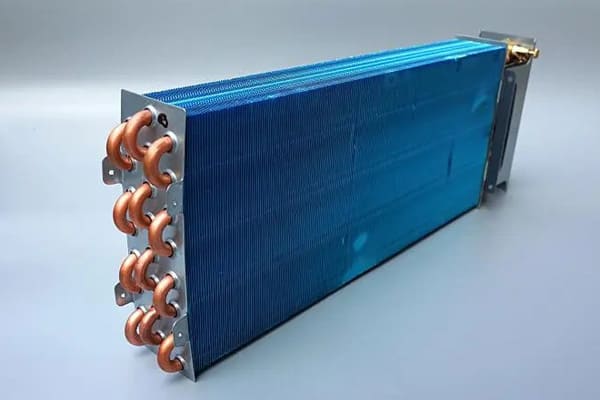

Air conditioner condenser

Ve zkratce, aluminum foil plays a very important role in air conditioning and refrigeration. It not only helps the refrigerant absorb and release heat quickly, but also has good corrosion resistance, strength and toughness. Proto, When we choose an air conditioner, we need to pay attention to the materials used, especially the materials of the evaporator and condenser, so as to ensure the cooling effect and service life of the air conditioner.

| Slitina | 1100/1200/3003/8011/8021 |

| Nálada | Ó、H14、H16、H22、H24、H26 |

| Tloušťka | 0.09mm-0.3mm |

| Šířka | 100-1300mm |

| Inside diameter | 76mm/152 mm |

| aplikace | Air conditioner condenser |

Air conditioner aluminum foil can be divided into 7 categories according to its processing technology and performance characteristics:

Uncoated aluminum foil refers to aluminum foil that has been rolled and annealed without any form of surface treatment. 10 years ago in our country, and about 15 years ago in foreign countries, the aluminum foil used for air-conditioning heat exchangers was all non-coated aluminum foil. Even at present, o 50% of the heat exchangers used in foreign developed countries are still non-coated aluminum foils, while in our country, this ratio is about 60%.

The so-called coated aluminum foil is to re-treat the surface of non-coated aluminum foil to make it have some special function. In Japan, Germany and other countries with rapid technological development, the use of coated aluminum foil has a history of more than 15 let. V mé zemi, the use of coated aluminum foil does not exceed 10 let.

The surface of corrosion-resistant aluminum foil products has a certain anti-corrosion protective layer. The air-conditioning heat exchanger made of this product can be used in relatively harsh areas and can significantly increase the service life of the air-conditioning. Ve stejnou dobu, due to the improvement of the corrosion resistance of the heat exchange fins, the generation of surface corrosion powder is greatly reduced, thereby improving the ventilation quality and purifying the air in the air-conditioning room.

Povrch hydrophilic aluminum foil has strong hydrophilicity. The hydrophilic performance is determined by the angle formed by water sticking to the surface of the aluminum foil. The smaller the angle a, the better the hydrophilic performance, a naopak, the worse the hydrophilic performance. Obecně řečeno, angle a is less than 35°. To znamená, it belongs to the hydrophilic property. Hydrophilic aluminum foil is generally used on condensers of air conditioners.

Hliníková hydrofilní fólie

Its main function is to make the moisture in the hot air easy to spread and flow down the sheet when it condenses into water droplets on the heat exchange sheet. This can avoid affecting the ventilation effect of the heat exchanger due to the “bridge” of water droplets between the heat exchange fins, thereby improving the heat exchange rate of the air conditioner and saving electricity under the same cooling capacity.

V současnosti, the general hydrophilic aluminum foil on the market not only has good hydrophilicity on the surface, but also has high corrosion resistance, so that the performance of the air conditioner is more optimized.

Hydrophobic aluminum foil is also called water-repellent aluminum foil, and its surface properties are just the opposite of those of hydrophilic aluminum foil. To znamená, when the condensed water condenses on the surface of the aluminum foil, the contact angle with the aluminum foil is relatively large, generally 75°. above. The larger the angle, the better the water repellency. The ultimate purpose of using hydrophobic aluminum foil is the same as that of hydrophilic aluminum foil, to je, to prevent condensed water from remaining between the heat exchange fins. The difference is that the hydrophobic aluminum foil achieves the purpose of removing the condensed water between the heat transfer fins by increasing the contact angle between the condensed water and the heat transfer fins, so that the condensed water forms water droplets that are easy to slide off.

In the process of processing the air-conditioning heat exchange fins, lubricating oil is generally added to the surface first, then punched and flanged, and finally the lubricating oil is washed away with trichlorethylene. Since trichlorethylene is harmful to the human body, in order to reduce this process, a self-lubricating aluminum foil was produced accordingly. Self-lubricating aluminum foil, as the name suggests, does not need to add lubricating oil separately during punching, and the lubrication during punching is borne by the pre-treated film on the surface of the aluminum foil. Since there is no need for special lubricating oil, the subsequent trichlorethylene cleaning and drying processes are also omitted.

Anti-mildew aluminum foil is mainly used in the indoor unit of the air conditioner. Its main function is to prevent the surface of the heat exchanger from becoming moldy due to use or storage for a long time, thereby significantly improving the ventilation quality of the air conditioner and preventing abnormal odors. Improve the environment in the air-conditioned room.

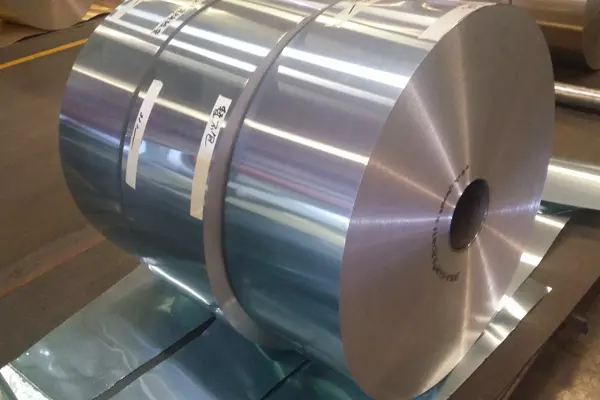

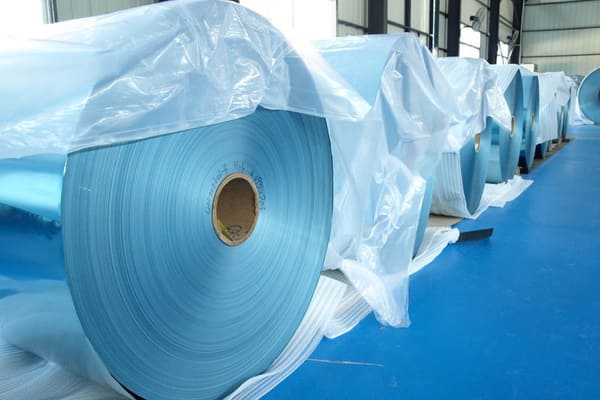

Air conditioner aluminum foil packaging

Air conditioner aluminum foil packaging

Air conditioner aluminum foil packaging

Air conditioner aluminum foil packaged

5454 hliníkový plech má silnou antikorozní schopnost a patří mezi 5000 série slitina hliníku a hořčíku. 5454 hliníkový plech je také tepelně neupravitelná slitina a je 20% silnější než 5052 hliníkový plech. Často se používá v potrubích námořních zařízení, hliníkové cisternové karoserie a další obory.

Barevně potažený hliníkový kruh se obvykle vztahuje na hliníkové kruhy s PE nebo PVDF povlakem na povrchu, které mohou nejen zlepšit některé antikorozní vlastnosti, ale také zlepšit vzhled produktu.

1060 Hliníková cívka se skládá z 99.6% hliník, který je podobný tomu 1050 slitina ze stejné rodiny, ale obsah hliníku se liší o 0.1%.

5052 hliníkový plech je součástí 5000 série hliníku. Typy této řady jsou legovány hořčíkem (2.5%) a mají střední až vysoké pevnostní vlastnosti.

Objevte perfektní směs síly a estetiky s černou deskou hliníkovou kontrolou. Ideální pro podlahy, rampy, a dekorativní rysy, Tento lehký materiál zajišťuje bezpečnost a styl v jakémkoli nastavení.

3003 hliníkový plech je slitina s velmi dobrou odolností proti korozi a střední pevností, důvod, proč je tento kov široce používán, je, že je cenově dostupný a pevný.

č.52, Dongming Road, Zhengzhou, Henan, Čína

Henan Huawei Aluminium Co., Ltd, Jeden z největších dodavatelů hliníku v Číně Henan,Jsme založena v roce 2001 a máme bohaté zkušenosti s dovozem a vývozem a vysoce kvalitními hliníkovými výrobky

Po – So, 8AM – 17:00

Neděle: ZAVŘENO

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Nejnovější komentáře

Plánuji obchodní cestu do Číny a velmi se zajímám o váš hliník 8011 Produkty pro výrobu kontejneru potravin. Chtěl bych navštívit vaši továrnu během mého pobytu v Číně: Podívejte se na své produkční linky (Fólie válcování, žíhání, rozřezání, balení). Diskutovat o specifikacích (8011-Ó temperament, Tloušťka 0,05–0,08 mm, Jumbo Roll). Zkontrolujte své certifikáty kvality a exportní zkušenosti. Mohl byste mi prosím dejte vědět: Your available dates for a visit The location of your factory If you can provide an invitation letter for my business visa (M Visa). Děkujeme za vaši laskavou podporu. Těšíme se na vaši odpověď. Nejlepší respekt: LOUNIS MUSTAPHA company name:TOP BARQUETTE SELECT [email protected] what's up:213 770 91 69 43

Ahoj ; Burak ünal i. Jsem úředník společnosti, která dodává výrobky pro obaly a čištění v Antalyi. Také dělám práci P.E Stretch Transfer. Naše stroje 9 Ve 10 Přenos mikronové hliníkové fólie bude revidovat. Co od tebe chci, 9 nebo 10 mikron 35 cm a 45 Cena CM Jumbo fooys pro fooy, Termin a já chci následující informace ; 35 Průměrná hmotnost cm jumbo fólie. 45 Průměrná hmotnost cm jumbo fólie. Je to proto, že to bude soud 2 Kolik stojí naše minimální tonáž. Užijte si svou práci.

Jsme výrobce částí a příslušenství pro komerční osvětlení v Egyptě níže, jsou naše současné požadavky na výrobní proces z hliníkové cívky (Slitina 1050 Tloušťka o tloušťce 0.3 mm width 25cm=10tons width 29.5cm=6tons width 33.5cm=5tons width 37 cm=5tons kindly send us your best quotation ASAP according to our company below details: Níže jsou uvedeny podrobnosti naší společnosti : Úplné jméno právní společnosti: Zaměřená Ligth pro průmyslové investice ., Co address: Plot č 8 - Prodloužení 4. průmyslového - Zóna Sadat - Minofia - egypt Telephone number Ahmed nseem +201016644789 & +201010879400 Moh el shref : Dav : +2 01016644789 Daňové identifikační číslo : 699-483-174

Píšu, abych se zeptal na produkty, které vaše společnost nabízí. Obzvláště mě zajímá níže uvedený produkt: *Aluminum Coil QTY-20 Units Could you please provide me with more information on these products, včetně cen, dostupnost, a jakékoli další podrobnosti, které mohou být relevantní? a také citujte vaši běžnou jednotkovou cenu za dodávku těchto produktů, Spolu s vaší diskontní cenou za objem nákupu plného nákladu kamionu. Poznámka: Navíc k výše uvedenému, Naše standardní platební podmínky:Čisté 15 dnů 30 dny od data dodávky s fakturou dodavatele.

Bonjour, Chtěl bych vědět, jestli děláte velké hliníkové listy ? dimenze přání: 2500mm x 8000 mm nalé 0,3 tloušťka . Jsem jednotlivec a žiji ve Francii za dodání. merci a vous d'avance Cordialement Mr NEVEU