Pvdf コーティングされたアルミニウム コイルは、カラー コーティングされたアルミニウム コイルの 1 つのタイプです。, カラーコーティングされたアルミニウムコイルはポリエステルに分割可能 (PE) コーティングされたアルミニウムコイル, フロロカーボン (PVDF) コーティングされたアルミニウムコイルとエポキシローラーコーティングされたアルミニウムコイル.

Pvdf コーティングされたアルミニウム コイル

Pvdf coated aluminum coil is a new type of material that is very popular at present. Pvdf coated aluminum coil have good environmental protection. Now is an era that pays more and more attention to environmental protection. Pvdf coated aluminum coils are resistant to saline, alkali and acid rain corrosion. They will not corrode or produce toxins, release any toxic gases, or cause keel damage. And the fixings are rusty and flame retardant.

材料: AL1050、AL1060、AL1100、AL3003、AL3004、AL3105、AL5005、AL5052

コーティング: fluorocarbon coating, polyester coating, wood grain, 印刷, varnish

厚さ: 0.25mm-4.00mm

コーティングの厚さ: PVDF ≥ 25micron, POLYESTER ≥ 18micron

色: CBCC, RAL and Pantone color cards or color matching according to customer samples.

Implementation standard: YS/T431-2009

代表的なアプリケーション: Widely used in interior decoration, 天井, 壁パネル, 屋根, 家具, various exterior walls and interiors.

特徴: This product has excellent weather resistance and high temperature drying varnish. It has the advantages of high gloss retention, good color stability, and small color difference changes. The warranty period of PE coating is about 15 年, and the warranty period of PVDF is about 30 年.

PVDF (フロロカーボン) coating is made of fluorocarbon resin, 顔料, and ester solvent as raw substances. The coating is baked and baked at high temperature and solidifies right into a dry film, which has awesome climate resistance. PVDF coating may be divided into conventional PVDF coating and nano PVDF coating.

White Pvdf Coated Aluminum Coil

あ. The traditional PVDF coating makes use of KYNAR500 PVDF. After to 3 coatings and baking, it has top acid and alkali resistance. It’s miles long lasting in harsh weather and environments and will now not fade for 15 年. In view of those statistics, we suggest the utility of this panel for exterior wall cladding.

B. Nano PVDF coating, which isn’t the same as conventional PVDF, is a transparent coating. It incorporates nano elements that protect the panel from pollutants, and since nano has a self-cleansing impact, it may easily cast off dirt and pollution from rain or water.

| Base material: | 1000 シリーズ, 3000 シリーズ, 5000 シリーズ, 6000 シリーズ, 8000 シリーズ, アルミニウム合金 |

| 厚さ: | 0.08-1.5 んん |

| 幅: | <1800mm |

| Coil core diameter: | 150んん, 405んん, 505んん, 508んん, 510んん |

| コーティングの厚さ: | PVDF ≥25mm, PE≥18mm |

| Color standard: | E < 2 or not obvious by visual inspection |

| ブリネル硬さ: | > 2HB |

| Coating glue: | Not less than first-level impact: no cracks (50kg/cm, ASTMD-2794:1993) |

| Bending strength: | >100次 |

| Boiling point: | no any distortion and color change (in the 99 more or less 1 degree

水, then cooling 2 時間) |

| Corrosivity: | surface deep in the 5% muriatic acid and 5% NaCL, interior deepin the 2% muriatic

acid and 2% NaCL, 後 48 時間, no change |

The multi-layer spraying process includes three sprays (three sprays for short), プライマー, topcoat, cover varnish and two sprays (primer and topcoat).

According to the thickness of the coating, it can be divided into single coating (4-20 ミクロン); 二重塗装 (25-28 ミクロン); three coatings (35-38 ミクロン).

Pvdf Coated Aluminum Coil Structure

Pvdf coated aluminum coil has excellent performance. Huawei Aluminum specializes in the production of Pvdf covered Aluminum Coil. It strictly controls product quality and ensures high-quality products. The following are the advantages of Pvdf coated aluminum coil:

耐久性: Pvdf coated aluminum coil is known for its exceptional durability, able to withstand harsh environmental conditions such as UV radiation, high temperatures and exposure to harsh chemicals.

耐薬品性: PVDF coatings are resistant to a wide range of chemicals, including acids, alkalis, および有機溶剤, making them ideal for use in industrial and commercial settings.

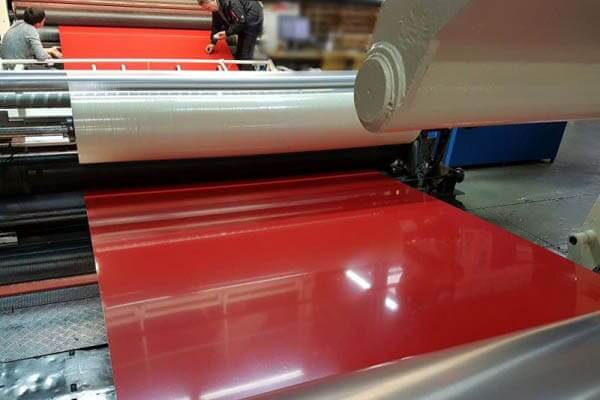

Pvdf Coated Aluminum Coil Production

UV抵抗: PVDF coatings have excellent resistance to UV radiation, making them ideal for outdoor applications exposed to sunlight.

LOW MAINTENANCE: Pvdf coated aluminum coil is easy to maintain, has a smooth surface and is resistant to dirt, grime and stains. They don’t require frequent cleaning or repainting, making them a low-maintenance option.

Excellent Adhesion: PVDF coatings have excellent adhesion to metal surfaces, ensuring they stay in place even in harsh conditions.

Wide Color Range: Pvdf covered Aluminum Coil is available in a variety of colors, including metallic and non-metallic options, allowing customization to suit the desired aesthetic.

Good Dimensional Stability: PVDF coatings have good dimensional stability, which means they do not expand or contract significantly with changes in temperature or humidity. This helps ensure that the coated metal maintains its shape and size over time.

持続可能性: PVDF coatings are a sustainable choice because they are made from fluoropolymers that can be recycled and reused.

ポリフッ化ビニリデン (PVDF) is a high-performance fluoropolymer commonly used as a coating material. Pvdf coated aluminum coil is known for its excellent durability, chemical resistance and UV resistance, 幅広い用途に適しています. Some common applications of Pvdf coated aluminum coil include:

Construction Applications: PVDF coated aluminum coils are commonly used to coat the exteriors of buildings and other structures such as cladding, roofs and window frames. These coatings protect against weathering, フェード, and other forms of damage.

産業用アプリケーション: PVDF coated aluminum coils are used to protect metal parts from corrosion, abrasion and other forms of wear and tear. They are commonly used in the aerospace, automotive and chemical processing industries.

消費者製品: PVDF coated aluminum coils are used to protect a variety of consumer products such as appliances, furniture and sporting goods. The coating protects against scratches, chips and other forms of damage.

Infrastructure: PVDF coated aluminum coils are used to protect various infrastructures such as bridges, highways and pipelines. These coatings protect against corrosion, UV radiation and other forms of damage.

その他の用途: PVDF coated aluminum coils are also used in various other applications such as medical equipment, electrical insulation, and food processing equipment.

Inner core: paper core or steel core

Outer layer: moisture-proof plastic + cardboard

Pallet: wooden pallet

Pvdf Coated Aluminum Coil Package

6000 シリーズアルミニウム合金は、次のもので構成されるアルミニウム合金の一種です。 90-94% アルミニウム, 残りで 6-10% マグネシウムなどの他の元素で構成される, ケイ素, そして銅.

陽極酸化アルミニウムシートは、対応する電解液に置かれたアルミニウムシートです。 (硫酸など, クロム酸, シュウ酸, 等) 陽極として, 電気分解は特定の条件と外部電流の作用下で実行されます。.

1100 アルミニウムコイルは、すべてのアルミニウムグレードの中で最高の商業純度を備えた合金です。, アルミニウム含有 (質量分率) の 99.00%. 強度は比較的低いです, そして延性に優れています, 成形性, 溶接性, 耐食性.

河南華為アルミニウム有限公司, 株式会社, 中国河南省最大のアルミニウムサプライヤーのひとつ,私たちは2001年に設立され、輸出入と高品質のアルミニウム製品の豊富な経験があります

月~土, 8午前 – 午後 5 時

日曜日: 閉まっている

© 著作権© 2023 河南華為アルミニウム有限公司, 株式会社

最新のコメント

拝啓, アルミニウム 7075-T651 のプロバイダーを探しています。 1.0 または 1.5 厚さmm. 必要なのは約 180 のプレート 200 mm× 200 んん. こちらの見積もりと納期を教えていただけますか? よろしくお願いします. 敬具, フランシスコ・シルバ

こんにちは, このメッセージがあなたにうまく届くことを願っています. 貴社のウェブサイトを熟読しましたので、製品の詳細な価格見積もりが必要です; このメッセージにご返信いただきましたら、この注文/プロジェクトに関する詳細をお送りします。. あなたと取引できることを楽しみにしています. 温かい感謝を. よろしくお願いします, Ahmet Emir Purchase Manager SER MEKATRONIK SANAYI VE TICARET LTD.STI. トゥルクク O.S.B. マハレシ 216.ソカク NO:5/1 縮れた / テキルダーグ / Turkey Email: [email protected]

引用が必要です 3000 シリーズのアルミニウムシート/コイル (3104 H19) マグロは生産できます, フードグレードフィニッシュ, Mazzatlánへの配達, メキシコ.

私は中国への出張を計画しています、そして私はあなたのアルミニウムに非常に興味があります 8011 食品容器生産用の製品. 中国での滞在中にあなたの工場を訪問したい: あなたの生産ラインを参照してください (ホイルローリング, アニーリング, スリッティング, パッキング). 仕様について話し合います (8011-ああ、気性が荒い, 厚さ0.05〜0.08 mm, ジャンボロール). 質の高い証明書と輸出経験を確認してください. 教えていただけませんか: Your available dates for a visit The location of your factory If you can provide an invitation letter for my business visa (Mビザ). あなたの親切なサポートをありがとう. あなたの返事を楽しみにしています. 宜しくお願いします: LOUNIS MUSTAPHA company name:TOP BARQUETTE SELECT [email protected] what's up:213 770 91 69 43

こんにちは ; Burakünali. 私はAntalyaで包装製品とクリーニング製品を提供する会社の職員です. また、P.Eストレッチ転送ジョブも行っています. 私たちの機械 9 ve 10 ミクロンアルミホイル移動を修正します. 私があなたに欲しいもの, 9 または 10 ミクロン 35 CMと 45 FOOYのCMジャンボFOOYS価格, 終了と私は次の情報が欲しいです ; 35 CMジャンボホイルの平均重量. 45 CMジャンボホイルの平均重量. これは、裁判になるためです 2 最低注文トン数はいくらですか. あなたの仕事を楽しんでください.