1100 aluminum sheet is one of the representatives of the 1 series pure aluminum plate, and it is also the most widely used alloy.

1100 aluminum plate is one of the representatives of the 1 series pure aluminum plate, and it is also the most widely used alloy. It is often used in industrial and daily aluminum, and its aluminum content is as high as 99.00%;

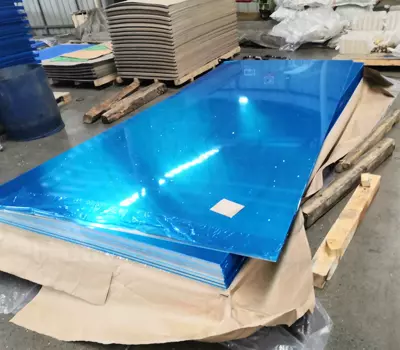

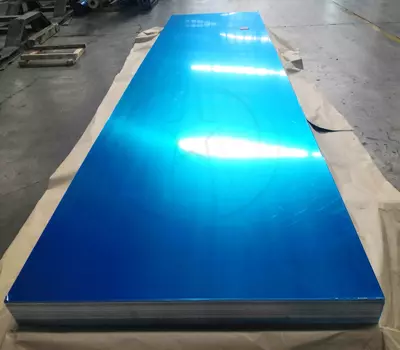

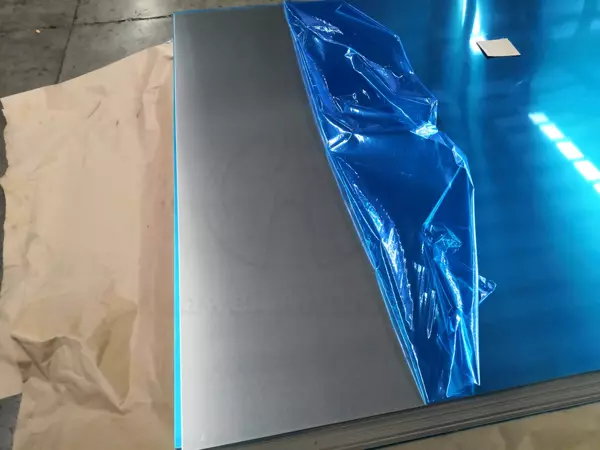

1100 aluminum sheet with pvc blue film

1100 aluminum sheet has excellent formability, especially in the fully softened annealed condition. It may be suitable for applications requiring bending, rotating, drawing, stamping and rolling. It has good thermal conductivity and is commonly used in heat exchangers and radiators in electrical applications.

Aluminium 1100 is just one of several common aluminium alloys and has a 99.00% aluminium content, with the remaining elements including copper, iron, magnesium, manganese, silicon, titanium, vanadium and zinc.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: Each |

Others: Total |

Al: Min. |

| 1100 | 0.95 Si + Fe | 0.05~0.20 | 0.05 | – | – | 0.1 | – | 0.05 | 0.15 | 99.0 | |

Table Source: 1100 aluminum sheet parameter

AL 1100 also has different performance in different tempers. The following is the performance analysis table of 1100 aluminum sheet in different tempers:

| Conditions | Tensile Properties | ||

| T (°C) | Treatment | ||

| 25 | Aluminum 1100 H12 | Tensile Strength (MPA) | 110 |

| Yield Strength (MPa) | 105 | ||

| Elongation (%) | 12 | ||

| Reduction in Area (%) | |||

| 25 | Aluminum 1100 H14 | Tensile Strength (MPA) | 125 |

| Yield Strength (MPa) | 115 | ||

| Elongation (%) | 9 | ||

| Reduction in Area (%) | |||

| 25 | Aluminum 1100 H16 | Tensile Strength (MPA) | 145 |

| Yield Strength (MPa) | 140 | ||

| Elongation (%) | 6 | ||

| Reduction in Area (%) | |||

| 25 | Aluminum 1100 H18 | Tensile Strength (MPA) | 165 |

| Yield Strength (MPa) | 150 | ||

| Elongation (%) | 5 | ||

| Reduction in Area (%) | |||

| 25 | Aluminum 1100 0 | Tensile Strength (MPA) | 90 |

| Yield Strength (MPa) | 34 | ||

| Elongation (%) | 35 | ||

| Reduction in Area (%) | |||

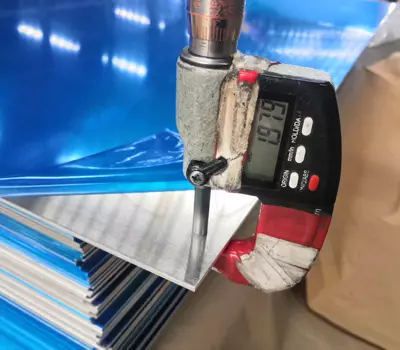

1100 aluminum sheet produce

Cold working is the most common method of forming aluminum 1100. A cold working process is any metal forming or molding process at or near room temperature.

Aluminum 1100 is one of the softest aluminum alloys and is therefore not used for high strength or high pressure applications.

Related:How to get 1100 aluminum sheets?

| Properties | Conditions | ||

| T (°C) | Treatment | ||

| Density (x1000 kg/m2) | 2.71 | 25 | |

| Poisson’s Ratio | 0.33 | 25 | |

| Elastic Modulus (GPa) | 70-80 | 25 | |

| Tensile Strength (Mpa) | 110 | 25 | H12 |

| Yield Strength (Mpa) | 105 | ||

| Elongation (%) | 12 | ||

| Reduction in Area (%) | |||

| Hardness (HB500) | 28 | 25 | H12 |

| Shear Strength (MPa) | 69 | 25 | H12 |

| Fatigue Strength | 41 | 25 | H12 |

While it is usually cold worked, pure aluminum can also be hot worked, but more commonly aluminum is formed by spinning, stamping and drawing processes that do not require the use of high temperatures. These processes produce aluminium in the form of foils, sheets, rods or bars, sheets, strips and wires.

Aluminum 1100 can also be welded; resistance welding is possible but can be difficult and usually requires the attention of a skilled welder.

| Properties | Conditions | ||

| T (°C) | Treatment | ||

| Thermal Expansion (10 -6/C°) | 23.6 | 25 | |

| Thermal Conductivity (W/m-K) | 218 | 25 | H18 |

| Properties | Conditions | ||

| T (°C) | Treatment | ||

| Electric Resistivity (10 -9 O-m) | 30 | 25 | H18 |

Aluminum 1100 can be formed into many different products, including chemical equipment, railroad tank cars, tailplanes, dials, nameplates, cookware, rivets, reflectors, and sheet metal. Aluminum 1100 is also used in the plumbing and lighting industries, among various other industries.

5086 aluminum sheet is a high-strength, corrosion-resistant al-mg alloy, widely used in aerospace, transportation, architectural decoration and other fields.

The 6063 aluminum sheet is a 6000-series aluminum alloy with magnesium and silicon as the main alloying elements. The strength of the 6063 alloy is lower than that of the 6061 alloy, and it has good extrudability, corrosion resistance, and good surface treatment performance.

Pharmaceutical foil, also known as medical-grade foil or blister foil, 8011,8021,8079 aluminum foil common used for Pharmaceutical packaging foil.

Explore the unique properties, manufacturing processes, and wide-ranging applications of 1060 aluminum foil. Learn why this high-purity alloy is essential in packaging, electronics, HVAC, and more.

5052 aluminum sheet is part of the 5000 series of aluminum. The grades in this series are alloyed with magnesium (2.5%) and have medium to high strength properties.

Aluminum foil is one of the components of power capacitor equipment. The addition of aluminum foil material can not only improve the quality of the capacitor, but also increase the voltage resistance of the capacitor while ensuring the performance and life of the capacitor.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

I need a quotation for 3000 series aluminum sheets/coils (3104 H19) for tuna can production, food-grade finish, delivery to Mazatlán, Mexico.

I am planning a business trip to China and I am very interested in your aluminium 8011 products for food container production. I would like to visit your factory during my stay in china: See your production lines (foil rolling, annealing, slitting, packing). Discuss specifications (8011-O temper, thickness 0.05–0.08 mm, jumbo roll). Review your quality certificates and export experience. Could you please let me know: Your available dates for a visit The location of your factory If you can provide an invitation letter for my business visa (M visa). Thank you for your kind support. Looking forward to your reply. Best regard: LOUNIS MUSTAPHA company name:TOP BARQUETTE SELECT [email protected] what's up:213 770 91 69 43

Merhaba ; Burak ÜNAL ben. Antalya ' da Ambalaj ve Temizlik ürünleri tedarik eden bir firmanın yetkilisiyim. Ayrıca P.E Streç aktarım işi yapmaktayım. Makinalarımızı 9 ve 10 micron alüminyum folyo aktarımına uyacak şekilde revize edeceğiz. Sizden istediğim, 9 veya 10 micron olacak şekilde 35 cm ve 45 cm jumbo folyolar için fiyat, termin ve şu bilgileri istiyorum ; 35 cm jumbo folyonun ortalama ağırlığı. 45 cm jumbo folyonun ortalama ağırlığı. Deneme olacağı için bu 2 ölçüde minimum sipariş tonajımız ne kadar olması gereklidir. İyi çalışmalar.

We are A Commercial Lighting 's parts and accessories Manufacturer in egypt below is our current requirements for production process from aluminum coil (Alloy 1050 temper O thickness 0.3 mm width 25cm=10tons width 29.5cm=6tons width 33.5cm=5tons width 37 cm=5tons kindly send us your best quotation ASAP according to our company below details: Below is our company details : Full legal company name: Focused ligth for industrial investment ., Co address: Plot no 8 - extension of 4th industrial - zone sadat - minofia - egypt Telephone number Ahmed nseem +201016644789 & +201010879400 Eng Moh El shrief : Mob : +2 01016644789 Tax ID number : 699-483-174

I am writing to inquire about the products that your company offers. I am particularly interested in the product listed below: *Aluminum Coil QTY-20 Units Could you please provide me with more information on these products, including pricing, availability, and any additional details that may be relevant? and also quote your ordinary unit price for supplying these product, together with your discount price for the volume purchase of full truck load. Note: Additionally to the above, our standard Payment Terms:Net 15days to 30 days from the date of supply with the supplier's Invoice.