5005 aluminum sheet is a medium-strength aluminum alloy plate, which can reach medium and high strength by cold working, and it has good formability

5005 aluminum sheet belongs to 5 series Al-Mg alloy, but the main alloy Mg content is lower than other 5 series alloys, containing 0.8% magnesium, so its corrosion resistance is slightly higher than 3 series alloys;

5005 aluminum alloy is an aluminum alloy that is resistant to atmospheric corrosion. It is used in decorative and architectural applications;

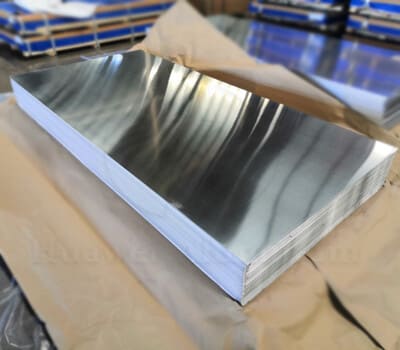

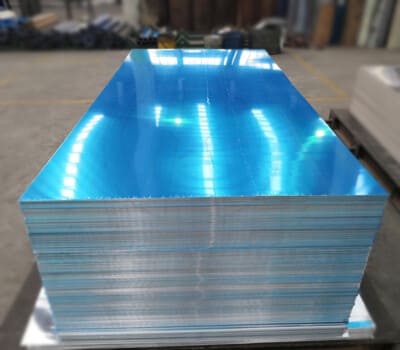

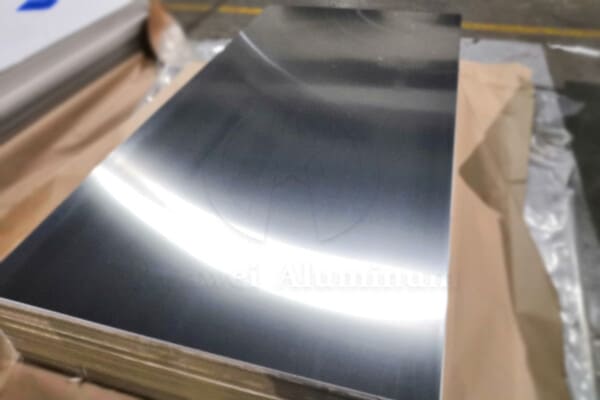

5005 Aluminum Sheet Display

5005 aluminum sheet is a medium-strength aluminum alloy sheet that can be cold worked to achieve medium-high strength. It has good formability and is suitable for applications that require bending, spinning, drawing, stamping, and roll forming. It is typically used in applications that require anodizing.

| Al | Mg | Fe | Si | Zn | Cu | Mn | Cr |

| 97-99.5% | 0.50 – 1.10% | 0 – 0.70% | 0 – 0.30% | 0 – 0.25% | 0 – 0.20% | 0 – 0.20% | 0 – 0.10% |

Chemical Composition conforms to Chinese, American, and European standard specification

Table Resource: Wikipedia

Compared with other aluminum alloy series, it has higher welding strength, workability and corrosion resistance.

It also has the low density and excellent thermal conductivity common to aluminum alloys. It is the most commonly used sheet and sheet form of aluminium.

5005 Aluminum Sheet For Building Decoration

The performance of 5005 aluminum alloy is similar to that of 3 series 3003 aluminum alloy, with moderate strength, good fusion, workability and formability, but its anodic oxidation effect is better than 3003 aluminum alloy, and the oxide film is brighter, and can reach the same level as 6063 alloy. color! Therefore, 5005 aluminum sheet is often used in high-end wide-width curtain wall panels, architectural decorations, automotive interior materials, instrument panels, oxidized materials, cookware, conductors, etc.

Note that although alloy 5005 is suitable for anodizing, streaks may occur.

| Property | At | Value | unit |

| Density | 20°C | 2,700 | kg/m³ |

| Melting Range | 632 – 655 | °C | |

| Modulus of Elasticity | |||

| Tension | 20°C | 68.2 | GPa |

| Torsion | 20°C | 25.9 | GPa |

| Compression | 20°C | 69.5 | GPa |

| Specific Heat | 20°C | 900 | J/kg. °C |

| Mean Coefficient of Expansion | 20°C | 23.75 | x 10 -6 / °C |

| Thermal Conductivity | 25°C | 201 | W / m. °C |

| Electrical Resistivity | 20°C | 0.034 | micro-ohm . m |

| Electrical Conductivity | |||

| Equal Volume | 20°C | 52 | % IACS |

| Equal Weight | 20°C | 172 | % IACS |

| Temper | 0.2% Proof Stress, MPa min † | Tensile Strength, MPa | Elongation % min ‡ |

| O (annealed) | 35 | 105 – 145 | 12 – 22 |

| H12 | 95 | 125 – 165 | 2 – 8 |

| H14 | 115 | 145 – 185 | 1 – 6 |

| H16 | 135 | 165 – 205 | 1 – 3 |

| H18 | – | > 185 | 1 – 3 |

| H32 | 85 | 115 – 160 | 3 – 9 |

| H34 | 105 | 135 – 180 | 2 – 7 |

| H36 | 125 | 160 – 200 | 1 – 4 |

| H38 | – | > 180 | 1 – 4 |

H34 – Stabilised – A low temperature thermal treatment or heat introduced during manufacture which stabilises the mechanical properties and relieves residual internal stress, plus usually improves ductility.

Tempers H116 and H321 can be used in fresh and salt water.

5005 aluminum sheet has the same high corrosion resistance as other non-heat treatable aluminum alloys. It also has high resistance to weak alkaline conditions common to 5000 series alloys.

The atmospheric corrosion resistance of 5005 is similar to that of 3003.

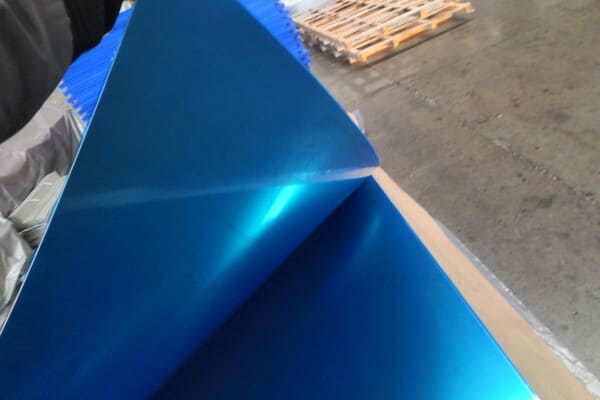

5005 Aluminum Sheet Covered With Blue Film

When anodizing is used to improve corrosion resistance, the film on 5005 is clearer than that on 3003 Aluminum Sheet, and the color matching with 6063 architectural profiles is better.

The corrosion resistance of aluminum alloys depends on the protective oxide film on the surface. When damaged, the rapid reaction of aluminum and oxygen can be easily repaired.

But if the film cannot be repaired, the high reactivity of base metals can lead to rapid corrosion, so aluminum alloys are not suitable for use with reducing media.

5005 can be easily handled by conventional methods. It should be processed at high speed and fully lubricated to avoid thermal deformation of the workpiece. Sharp tools are essential.

High speed steel or tungsten carbide can be used. The cut should be deep and continuous, and the cutting speed should be high. Woodworking machinery may be suitable for short-term jobs.

Machining of 5005 Aluminum Plate

5005 can be easily soldered by standard techniques. Usually tungsten gas arc welding (TIG) or gas shielded welding (MIG) welding. Aluminum must be very dry and clean to avoid weld contamination and porosity.

Use filler metal 1100, 4043 or 4047. 4043 is the most crack resistant. Use 1188 fill metal for best color matching. The shielding gas must be dry and free of hydrogen.

Aluminum 5005 is annealed at 345°C, the time and cooling rate at this temperature are not critical. Stress relief is rarely required, but can be done at around 220°C, if there is concern about strength loss, a stress relief test should be performed.

5005 is the Aluminum Association (AA) designation for this material. In European standards, it will be given as EN AW-5005. AlMg1(B) is the EN chemical designation. N41 is the British Standard (BS) designation. And A95005 is the UNS number.

It has been in use since 1935, but has only received its standard designation in 1954.

5005 Aluminum Sheet Production Process

Aluminum 5005 is generally not hot worked. It is easily cold formed in the annealed condition because it is a relatively soft and ductile alloy. Forming loads and tool and press wear are generally less than carbon steel. For punching and blanking, the punch to die clearance should be approximately 6% of the thickness of each side in H32 and H34 conditions. Sharp tools are required.

5005 aluminum alloy commonly available in flat rolled coil,Henan Huawei provides high quality 5005 Aluminum Sheet, welcome to order.

Typical Applications: Architectural applications, general sheet metal processing, high strength foils.

Alloy 5005 is commonly used in:

5005 Aluminum Sheet For Tank

5454 aluminum sheet has strong anti-rust ability and belongs to the 5000 series aluminum-magnesium alloy. 5454 aluminum sheet is also a non-heat treatable alloy and is 20% stronger than 5052 aluminum sheet. It is often used in marine facilities pipelines, aluminum tank car bodies and other fields.

Our commitment to quality, variety, and customization ensures that you'll find the perfect insulation aluminum coil for your project.

Explore the unique properties, manufacturing processes, and wide-ranging applications of 1060 aluminum foil. Learn why this high-purity alloy is essential in packaging, electronics, HVAC, and more.

3005 aluminum plate belongs to Al-Mn alloy. The strength of 3005 aluminum plate is about 20% higher than that of 3003 aluminum plate, and its corrosion resistance is also better.

6082 aluminum sheet can be heat treated, strengthened and has good formability, weldability and machinability, also known as structural alloy.

Huawei Aluminum aluminum discs are widely exported to Ghana, Guatemala, Burkina Faso, Algeria, Togo, Kenya, Nigeria, South Africa, Morocco and other African countries; the United Arab Emirates, Yemen, Qatar, Kuwait, Iran, Jordan, Saudi Arabia and other Middle East nation.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

2000x3000mm aluminum sheet Price and transport

Our required qty: Aluminium Sheet in coil (620mm X 1.20mm) Qty: 200 MT. Can you give me the number of contact urgently. Thanks Matiur Rahman Director of Technical Sales dept.

Bonjour ; Nous sommes une compagnie de spectacle de rue " compagnie carabosse " nous travaillons avec la flamme . nous sommes à la recherche de tôle reflecteur en aluminium pour pouvoir crée un nouvelle objet à base d'un fil métal enflammé liquide éthanol d' une hauteur environ 1 m . Quels produits avez vous à nous proposez ? Cordialement Fabrice

Hello, I am interested in 3*1500*3500 mm 5754 H111 Checkered Aluminium Plate - Diamond Shape Powermaster Ltd. Moscow, Volokolamskoe shosse 1, str. 1, of. 19, Moscow, 125080

Buenos días, Me interesaría saber el costo de Paneles de nido de abeja de aluminio para usar como refuerzo interior de bandejas, estantes , mesadas que realizamos en acero inoxidable AISI 304. De espesor del panel de 10 y 20 mm, con la piel superior e inferior de aluminio espesor 0.8 mm liso o cepillado o solo el núcleo del nido de abeja de aluminio; con tamaño de celda de 10 o 15 mm ( o estándar ) . tamaño de las planchas de 1500 x 3000 mm o la lo que recomiende para el uso que le quiero dar. Desde ya muchas gracias