5454 aluminum sheet has strong anti-rust ability and belongs to the 5000 series aluminum-magnesium alloy. 5454 aluminum sheet is also a non-heat treatable alloy and is 20% stronger than 5052 aluminum sheet. It is often used in marine facilities pipelines, aluminum tank car bodies and other fields.

5454 aluminum sheet is an aluminum sheet with strong anti-rust ability and belongs to the 5000 series aluminum-magnesium alloy. 5454 aluminum sheet is also a non-heat-treatable alloy and can be strengthened through cold working. Its strength is 20% higher than the medium-strength 5052 aluminum sheet.

5454 aluminum sheet plate

Aluminum 5454 has very good corrosion resistance, in particular to seawwater and general environmental conditions. Strength is medium to high and similar to ally 5754 with good strength in the temperature range 65 to 170 degrees centigrade. It has a high fatigue strength.

5454 aluminum alloy has excellent anti-rust properties. Therefore, we often see 5454 aluminum sheets in environments with high anti-rust requirements, such as marine facility pipelines, aluminum tank car bodies, automobile wheels, etc.

| Aluminum alloy | 5454 |

| Material temper | F, O, H12, H16, H19, H28, H32, H34, H36, H38, H111, H112, H114, H116, H321 |

| Thickness (mm) | 0.4-500 |

| Width (mm) | 20-2650 |

| Length (mm) | Customized |

| Delivery Terms | FOB, CFR, CIF |

| Elements | Si | Cu | Mg | Fe | Mn | Cr | Ti | Zn | Others | Al |

| Content | ≤0.25 | ≤0.10 | 2.4~3.0 | 0~0.4 | 0.50~1.0 | 0.05~0.2 | ≤0.2 | ≤0.25 | 0.05 | Remain |

Aluminum (Al): The primary component, making up the majority of the alloy.

Magnesium (Mg): It provides strength and enhances corrosion resistance.

Chromium (Cr): Contributes to improved corrosion resistance, especially in marine environments.

Manganese (Mn): A minor alloying element that helps with strength and workability.

Iron (Fe), Silicon (Si), Copper (Cu), and other trace elements: Present in small amounts, they can affect the alloy’s properties but are not major constituents.

| Property | Value |

|---|---|

| Density | 2.69 Kg/m3 |

| Melting Point | 645 °C |

| Thermal Expansion | 23.6 x 10-6 /K |

| Modulus of Elasticity | 70.5 GPa |

| Thermal Conductivity | 135W/m.K |

| Electrical Resistivity | 34% IACS |

Aluminum alloy 5454 corresponds to the following standard designations and specifications (not directly equivalent): A5454, ISO Al Mg3MN and Al 2.7Mg 0.8Mn Cr.

The following specifications cover Aluminum 5454

The most common states of 5454 aluminum are:

O – soft

H111 – The forming process produces some work hardening, but not to the extent required for H11 tempering.

H22 – Work hardened by rolling, then annealed to one quarter hardness.

H32 – Work hardened by rolling and then stabilized to one quarter hardness by low temperature heat treatment.

| Property | Value |

| Proof Strength | 180 Min MPa |

| Tensile Strength | 250 – 305 MPa |

| Hardness Brinell | 74 HB |

5454 aluminum sheet offers a range of favorable properties:

Corrosion Resistance: One of its key features is its exceptional corrosion resistance, making it suitable for marine applications.

Strength: 5454 aluminum has good strength, although it is not heat-treatable like some other alloys. Its strength can be enhanced through cold working.

Weldability: This alloy is highly weldable, making it suitable for various fabrication processes. It can be readily welded using common techniques such as MIG and TIG welding.

Formability: 5454 aluminum can be easily formed and shaped, making it versatile for different manufacturing processes.

Machinability: While it is not as easy to machine as some other aluminum alloys, it can still be machined using appropriate tools and techniques.

5454 aluminum sheet packged

5454 aluminum sheet finds applications in various industries, including:

Marine Industry: Due to its excellent corrosion resistance, it is commonly used in the construction of boat hulls, ship structures, and other marine components.

Automotive Industry: This alloy is used in the manufacturing of vehicle panels, such as inner and outer panels, floor panels, and automotive fuel tanks.

Pressure Vessels: It is suitable for manufacturing pressure vessels and storage tanks that require corrosion resistance and structural integrity.

Transportation: 5454 aluminum is used in the construction of trailers, truck bodies, and other transportation equipment.

General Sheet Metal Fabrication: It is also utilized in various general sheet metal applications where corrosion resistance and moderate strength are required.

The body of a tank truck is composed of coamings, anti-wave plates, tank mouths and other parts. Currently, the commonly used tank materials on the market include carbon steel, stainless steel, and aluminum alloy materials. With the development of lightweight, aluminum strip steel has become a craze. , the proportion of aluminum alloys in tank trucks is getting higher and higher.

5454-O aluminum sheet plate for tank truck body

The length of aluminum plates commonly used for tank trucks on the market is generally less than 12.5 meters, the width is less than 2.2 meters, and the common thicknesses are generally 5, 6, 7, and 8 mm. A complete tank truck body generally requires 4-6 aluminum plates to be welded.

The tank material is generally made of 5454 aluminum plate, 5083 aluminum sheet, etc. The O-state is softer, and the partition (wave-proof plate) part is made of 5083-O state. 5454 aluminum plate is a typical rust-proof aluminum and has high strength, about 20% higher than 5052 aluminum sheet.

Aluminum alloy tank trucks can not only significantly reduce the weight of the vehicle and improve transportation efficiency, but also have a long service life and are more environmentally friendly and safer. Throughout the entire life cycle, aluminum alloy tank trucks create higher overall profits than traditional carbon steel tank trucks.

5454 marine aluminum plates are mainly used for ship structural parts, internal pressure vessels, pipes and other parts such as speedboats, yachts, fishing boats, large cargo ships, etc. The 5454 ship plates required for different ship structural parts are also in different states.

Huawei Aluminum specializes in the production of 5454 marine aluminum plates. Leave your demand information and we will tailor-make 5454 marine aluminum plates suitable for you based on your actual usage conditions.

5454 marine aluminum plate

5454 marine aluminum plate is mainly used for hull structural parts, pressure vessels and pipelines. It is an aluminum plate with high strength, corrosion resistance and good weldability specially developed by Huawei Aluminum for the internal structure of ships.

Huawei Aluminum is a professional 5454 aluminum sheet supplier. There are its five advantages:

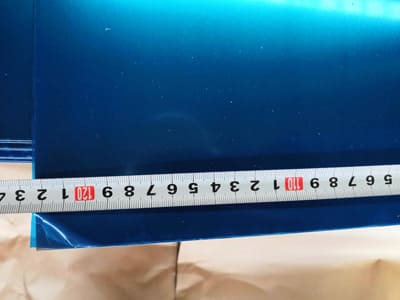

Length measurement |

Width measurement |

Diagonal measurement |

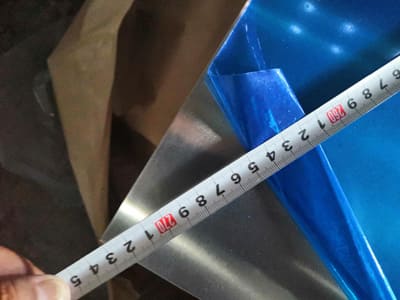

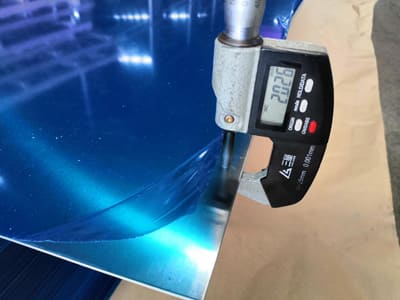

Thickness measurement |

5052 Aluminum Coil is an alloy composed of 2.5% magnesium and 0.25% chromium and is one of the most promising anti-rust aluminum materials

Aluminum foil is one of the components of power capacitor equipment. The addition of aluminum foil material can not only improve the quality of the capacitor, but also increase the voltage resistance of the capacitor while ensuring the performance and life of the capacitor.

3104 aluminum foil is a specialized alloy in the aluminum industry, renowned for its unique combination of strength, formability, and corrosion resistance. This article explores the chemical composition, mechanical properties, advantages, applications, and comparisons with similar alloys.

0.75 aluminum sheet refers to an aluminum sheet with a thickness of 0.75 inches, also known as 0.75" aluminum sheet;

1/8 aluminum sheet is often used in the manufacture of tanks and ships because of its strong hardness and corrosion resistance, etc.

Diamond plate aluminum sheets 4x8 is available in 6061-T6 and 3003-H14 sizes. they have higher strength, wear resistance, load-bearing, machinability, corrosion resistance, etc. Therefore, popular in construction, manufacturing, vehicles, ships and various fields.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

2000x3000mm aluminum sheet Price and transport

Our required qty: Aluminium Sheet in coil (620mm X 1.20mm) Qty: 200 MT. Can you give me the number of contact urgently. Thanks Matiur Rahman Director of Technical Sales dept.

Bonjour ; Nous sommes une compagnie de spectacle de rue " compagnie carabosse " nous travaillons avec la flamme . nous sommes à la recherche de tôle reflecteur en aluminium pour pouvoir crée un nouvelle objet à base d'un fil métal enflammé liquide éthanol d' une hauteur environ 1 m . Quels produits avez vous à nous proposez ? Cordialement Fabrice

Hello, I am interested in 3*1500*3500 mm 5754 H111 Checkered Aluminium Plate - Diamond Shape Powermaster Ltd. Moscow, Volokolamskoe shosse 1, str. 1, of. 19, Moscow, 125080

Buenos días, Me interesaría saber el costo de Paneles de nido de abeja de aluminio para usar como refuerzo interior de bandejas, estantes , mesadas que realizamos en acero inoxidable AISI 304. De espesor del panel de 10 y 20 mm, con la piel superior e inferior de aluminio espesor 0.8 mm liso o cepillado o solo el núcleo del nido de abeja de aluminio; con tamaño de celda de 10 o 15 mm ( o estándar ) . tamaño de las planchas de 1500 x 3000 mm o la lo que recomiende para el uso que le quiero dar. Desde ya muchas gracias