6082 aluminium strip can usually be heat treated for higher strength, but relatively low ductility.6082 aluminum alloy is one of the alloy models of...

6082 aluminium strip is one of the alloy models of the 6-series (aluminium – magnesium – silicon) aluminum alloy. Usually, 1 series, 3 series, and 5 series are non-heat treatable alloys, while 2 series, 6 series, and 7 series are heat treatable alloys, and 4 series are partially heat treatable and partially non-heat treatable.

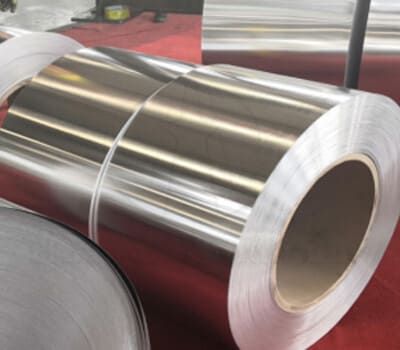

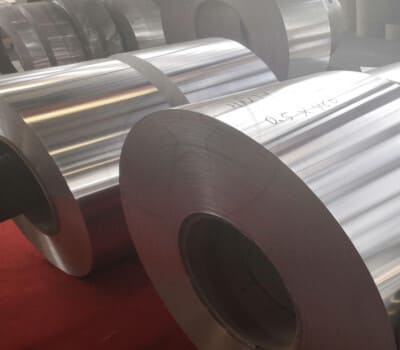

6082 Aluminium strip

6082 aluminum alloy can usually be heat treated for higher strength, but relatively low ductility.

The strength, welding performance, and corrosion resistance of the 6082 aluminum strip are very excellent, and it is mainly used in the transportation industry and the structural engineering industry.

| Element | Weight Percentage (%) |

| Aluminium | 95.2 to 98.3 |

| Chromium | 0.25 % max. |

| Copper | 0.1 % max. |

| Iron | 0.5 % max |

| Magnesium | 0.6 to 1.2% |

| Manganese | 0.4 to 1.0 % |

| Silicon | 0.7 to 1.3% |

| Titanium | 0.1 % max |

| Zinc | 0.2 % max |

| residuals | 0.15 % max |

| Properties | Value |

| Density | 2.71 gm/cc |

| Young’s modulus | 71 GPa |

| Ultimate tensile strength | 140 to 330 MPa |

| Yield strength | 260 MPa |

| Thermal Expansion | 23.1 μm/m-K. |

Note: Longitudinal mechanical properties of profiles at room temperature

Reference: Wikipedia

The 6082 alloy aluminum strip is characterized by containing the refractory metal Mn. The melting temperature should be controlled at 740-760℃. Stir evenly more than two times before sampling to ensure that the metal is completely melted, the temperature is accurate, and the composition is uniform.

After stirring, take a sample from the middle of the molten aluminum depth and from the left and right sides of the furnace for analysis. After passing the test, the converter can be converted.

Smelting process of 6082 aluminum strip

After the melt is transferred to a static furnace, powder spraying and jet refining are carried out with nitrogen and refining agent, refining temperature is 735-745 ℃, the time is 15 minutes, and static refining is 30 minutes after refining. Through this process, the melt is degassed, deslagged, and cleaned.

During the smelting and casting process, there are two filter devices between the mold and the furnace mouth, which are filtered by the foam ceramic filter plate (30PPI) at the furnace mouth. Before pouring, filter oxides and slag inclusions in the melt with a 14-mesh glass fiber cloth.

Smelting process of 6082 aluminum strip

6082 alloy has a higher casting temperature (compared to the 6063 normal processes), lower casting speed, and higher water flow. The above process should be strictly controlled and cannot exceed the scope, otherwise, it will easily lead to casting failure.

T6: Solution treatment + artificial aging. Users who have relatively low requirements for dimensional stability and elastic allowance accuracy can choose this tempering state.

T651: Solution Treatment + Tensile Stress Relief + Artificial Aging. T651 is usually used for precision workpieces to avoid elastic recovery after machining to maintain dimensional stability.

Compared with T6 tempering, the internal stress of T651 tempering will be smaller, and it is not easy to deform during processing.

6082-T6 vs 6082-T651

As a high-quality supplier and manufacturer in China, HUAWEI Aluminum has sold a large number of customers in 3003, 8011 and 6082 aluminum strips.

6082 aluminum strip packaging flow chart

You are welcome to order our hot-selling aluminum strip products. Our product packaging has high quality protection for the product.

If you have your own packaging suggestion, please contact our business department to follow up your product status in time.

Painted aluminum coil (Coated aluminum coil) is a popular material choice for construction, transportation, and signage due to its lightweight, durability, and versatility.

Pharmaceutical foil, also known as medical-grade foil or blister foil, 8011,8021,8079 aluminum foil common used for Pharmaceutical packaging foil.

3005 aluminum plate belongs to Al-Mn alloy. The strength of 3005 aluminum plate is about 20% higher than that of 3003 aluminum plate, and its corrosion resistance is also better.

Aluminum foil for hookah is commonly used for preparing and using a hookah, also known as a shisha or water pipe. It serves a specific purpose in the preparation of the hookah, particularly in the placement and management of the charcoal and tobacco.

Our 3003 Aluminum foil products have been exported to Australia, Morocco, Syria, Kuwait, Turkey, Saudi Arabia, UAE, Iraq, Jordan, Germany, Poland, Spain, Brazil, etc. We sincerely welcome you to visit our factory.

5005 aluminum coil refers to the 5005 aluminum plate after being cast and rolled and then processed into a coil shape by drawing and bending,

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sirs, I'm looking for a provider of aluminum 7075-T651 in 1.0 or 1.5 mm thickness. We need about 180 plates of 200 mm x 200 mm. Are you able to provide a quote and delivery time for this? Thank you so much in advance. Kind regards, Francisco Silva

Hello, I hope this message meets you well. I have perused your website and I want a detailed price quote for your product; upon your response to this message I will forward more details concerning this order/project to you. I look forward to doing business with you. Warm thanks. Best regards, Ahmet Emir Purchase Manager SER MEKATRONIK SANAYI VE TICARET LTD.STI. Turkgucu O.S.B. Mahallesi 216.Sokak NO:5/1 Corlu / Tekirdag / Turkey Email: [email protected]

I need a quotation for 3000 series aluminum sheets/coils (3104 H19) for tuna can production, food-grade finish, delivery to Mazatlán, Mexico.

I am planning a business trip to China and I am very interested in your aluminium 8011 products for food container production. I would like to visit your factory during my stay in china: See your production lines (foil rolling, annealing, slitting, packing). Discuss specifications (8011-O temper, thickness 0.05–0.08 mm, jumbo roll). Review your quality certificates and export experience. Could you please let me know: Your available dates for a visit The location of your factory If you can provide an invitation letter for my business visa (M visa). Thank you for your kind support. Looking forward to your reply. Best regard: LOUNIS MUSTAPHA company name:TOP BARQUETTE SELECT [email protected] what's up:213 770 91 69 43

Merhaba ; Burak ÜNAL ben. Antalya ' da Ambalaj ve Temizlik ürünleri tedarik eden bir firmanın yetkilisiyim. Ayrıca P.E Streç aktarım işi yapmaktayım. Makinalarımızı 9 ve 10 micron alüminyum folyo aktarımına uyacak şekilde revize edeceğiz. Sizden istediğim, 9 veya 10 micron olacak şekilde 35 cm ve 45 cm jumbo folyolar için fiyat, termin ve şu bilgileri istiyorum ; 35 cm jumbo folyonun ortalama ağırlığı. 45 cm jumbo folyonun ortalama ağırlığı. Deneme olacağı için bu 2 ölçüde minimum sipariş tonajımız ne kadar olması gereklidir. İyi çalışmalar.