Cable aluminum foil, also known as aluminum foil for cable, refers to a specific type of aluminum foil that is used in the manufacturing of cables and wires.

Cable aluminum foil, also known as aluminum foil for cable, refers to a specific type of aluminum foil that is used in the manufacturing of cables and wires.

Cable aluminum foil

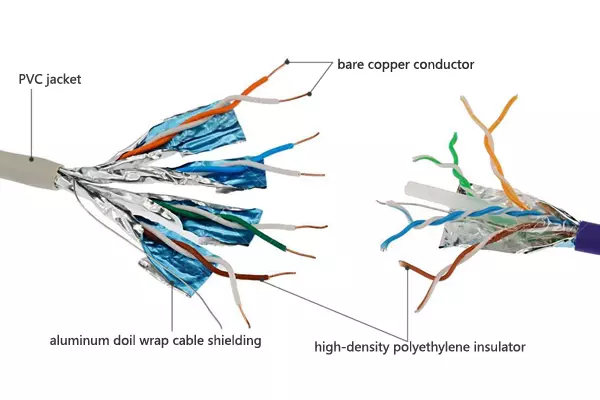

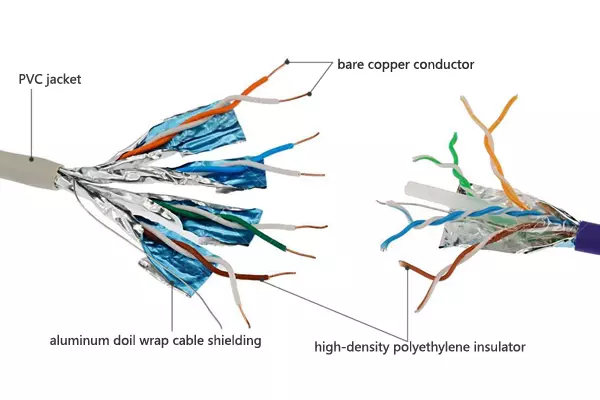

In cable production, aluminum foil is often used as a shielding material. It is wrapped around the inner core or conductor of the cable to provide protection against electromagnetic interference (EMI) and radio frequency interference (RFI). The aluminum foil acts as a barrier, preventing external signals from interfering with the transmission of electrical signals within the cable.

Shielding: The aluminum foil acts as a barrier to electromagnetic interference (EMI) and radio frequency interference (RFI). It helps to protect cables and other electronic components from external electromagnetic signals that may cause interference or disrupt their functioning.

Insulation: Aluminum foil tape can provide thermal insulation by reflecting heat. It is often used to wrap and seal air ducts, pipes, and cables to prevent heat loss or gain, improving energy efficiency.

Moisture and vapor barrier: The aluminum foil layer provides a moisture and vapor barrier, helping to protect cables and other components from moisture, condensation, and environmental factors.

Conductivity: Aluminum is a good conductor of electricity, so the foil layer can enhance the conductivity of the tape, making it useful in grounding applications.

cable shielding aluminum foil

| Specification | Description |

|---|---|

| Material | Aluminum foil |

| Thickness | Typically ranging from 0.01mm to 0.05mm |

| Width | Varies, commonly available in 10mm to 1000mm |

| Length | Varies, typically supplied in rolls or spools |

| Alloy | Typically made from high-purity aluminum alloys |

| Conductivity | High electrical conductivity |

| Shielding Effectiveness | Provides effective EMI and RFI shielding |

| Surface Treatment | Can be plain, coated, or laminated |

| Adhesive Layer | May have a pressure-sensitive adhesive on one side |

| Flexibility | Thin and flexible for easy application |

| Packaging | Often supplied in rolls or spools |

Industrial sites often harbor intricate electromagnetic noise environments, where the propagation or transmission of such noise can profoundly disrupt the smooth operation of electromechanical equipment. Amidst this intricate interplay, one prominent source of electromagnetic noise manifests in the diverse cables employed in production line equipment.

8011-O Cable aluminum foil

The aluminum foil used for cable shielding is typically thin and lightweight, ensuring flexibility and easy application during the cable manufacturing process. It is made of high-quality aluminum with excellent conductivity properties to ensure efficient shielding performance.

Cable aluminum foil plays a crucial role in maintaining the integrity and reliability of electrical signals in cables, particularly in applications where signal quality and data transmission are critical, such as in telecommunications, networking, and audio/video cables.

The common temper of aluminum foil used for Cable aluminum foil is O

Building insulation

Efficient wall insulation saves costs and floor space A foil-base insulation layer can avoid the need for an inner brick skin. The inner surface is an insulated framed dry lining. A foil-foam lining reduced the wall thickness and maximised the available floorspace in an apartment building.

Maximising available light

Alufoil laminate doesn’t only help to keep temperatures under control, the highly reflective surface can make the most of available and artificial light – an added cost saving.

Pipework insulation

Pre-formed phenolic resin pipework insulation with a protective coat of alufoil. Adding to the insulation, the foil also protects the surface of the plastic from damage.

Aluminum foil for pipework insulation

Adhesive tapes

Highly reflective and durable alufoil adhesive tape is available in widths up to 30 cm. As well as efficiently joining insulation materials in, for example, pipework installations, self adhesive alufoil may beused for small scale tasks such as RF screening in electronic equipment etc.

Health and safety

Insulation is not just for buildings. This fast ferrycar deck is lined with an insulating and fire resistant alufoil composite, so enhancing passenger, vehicle and vessel safety. Roof insulation going into place on a large warehouse project. The work is fast and efficient and poses no occupational health problems – no need for special protective clothing or other safety measures.

Ensuring efficient cabling

In communication cables, aluminium foil gives long-term insulation against moisture and attack from naturally occurring corrosive elements found above and below the ground. Aluminium foil also acts as an insulator against the magnetic and radio frequency fields associated with metal electrical cables.

As a sheath for fibre-optic cables, aluminium foil’s electrical conductivity enables the testing of the integrity of cablelinks.

Packaging of cable aluminum foil

Aluminum foil containers made of aluminum foil can be processed into various shapes, common alloys are 8011, 3003, 3004, 5052 aluminum foil.

1050 aluminum strips belongs to the family of commercially pure malleable 1000 series alloys, and the aluminum is 99 pure. 5%, with excellent molding processing characteristics, high corrosion resistance, good electrical and thermal conductivity.

Aluminum foil for hookah is commonly used for preparing and using a hookah, also known as a shisha or water pipe. It serves a specific purpose in the preparation of the hookah, particularly in the placement and management of the charcoal and tobacco.

8006 aluminum foil is a specific alloy known for its excellent barrier properties, making it ideal for packaging applications. It provides effective protection against moisture, light, and oxygen, helping to preserve the freshness and quality of food products.

6000 series aluminum alloy is a type of aluminum alloy that is composed of 90-94% aluminum, with the remaining 6-10% consisting of other elements such as magnesium, silicon, and copper.

Aluminum strip for transformer means that aluminum strip is used as conductive material in the high and low voltage windings of dry-type transformers and oil-immersed transformers.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

2000x3000mm aluminum sheet Price and transport

Our required qty: Aluminium Sheet in coil (620mm X 1.20mm) Qty: 200 MT. Can you give me the number of contact urgently. Thanks Matiur Rahman Director of Technical Sales dept.

Bonjour ; Nous sommes une compagnie de spectacle de rue " compagnie carabosse " nous travaillons avec la flamme . nous sommes à la recherche de tôle reflecteur en aluminium pour pouvoir crée un nouvelle objet à base d'un fil métal enflammé liquide éthanol d' une hauteur environ 1 m . Quels produits avez vous à nous proposez ? Cordialement Fabrice

Hello, I am interested in 3*1500*3500 mm 5754 H111 Checkered Aluminium Plate - Diamond Shape Powermaster Ltd. Moscow, Volokolamskoe shosse 1, str. 1, of. 19, Moscow, 125080

Buenos días, Me interesaría saber el costo de Paneles de nido de abeja de aluminio para usar como refuerzo interior de bandejas, estantes , mesadas que realizamos en acero inoxidable AISI 304. De espesor del panel de 10 y 20 mm, con la piel superior e inferior de aluminio espesor 0.8 mm liso o cepillado o solo el núcleo del nido de abeja de aluminio; con tamaño de celda de 10 o 15 mm ( o estándar ) . tamaño de las planchas de 1500 x 3000 mm o la lo que recomiende para el uso que le quiero dar. Desde ya muchas gracias