Flexible packaging aluminum foil is a thin foil made of aluminum that is commonly used in food packaging and pharmaceutical packaging. Unlike hard aluminum foil, flexible packaging aluminum foil is soft and can adapt to various shapes of containers, so it is widely used for packaging food and medicine.

Flexible packaging aluminum foil is a thin foil made of aluminum that is commonly used in food packaging and pharmaceutical packaging. Unlike hard aluminum foil, flexible packaging aluminum foil is soft and can adapt to various shapes of containers, so it is widely used for packaging food and medicine.

Flexible packaging aluminum foil is characterized by good airtightness and water resistance, which can protect food and medicine from oxygen ingress and moisture volatilization, thereby prolonging the freshness of food and the shelf life of medicines. In addition, flexible packaging aluminum foil also has corrosion resistance and light-shielding properties, which can prevent food and medicine from being corroded by photooxidation and maintain their original quality.

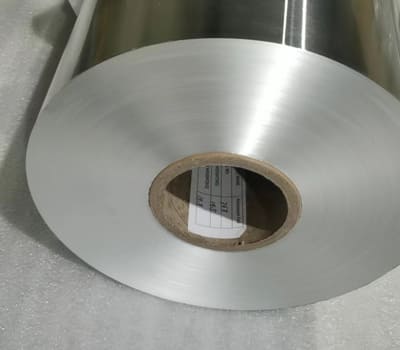

flexible packaging aluminum foil

Another advantage of flexible packaging aluminum foil is that it is easy to carry and open, which is convenient for consumers to use. At the same time, flexible packaging aluminum foil can also print various patterns and characters, which can increase product aesthetics and brand value.

In short, flexible packaging aluminum foil is a high-quality food and pharmaceutical packaging material, which has the advantages of airtightness, water resistance, corrosion resistance and light shading, which can protect the freshness and quality of products, and at the same time facilitate the use of consumers and increase the aesthetics of products.

The aluminum foil alloy grades selected for flexible packaging are mainly 1000 series and 8000 series. From the composition point of view, 1000 series contains more other alloy components than 8000 series. Therefore, in terms of the processability of aluminum foil for flexible packaging, the performance of 8000 series aluminum foil will be better.

It is superior and has better processability than the 1000 series. Among them, 8011, 8021, and 8079 aluminum foils are the key products of the 8000 series aluminum foils. With their excellent sealing, plasticity, and corrosion resistance, they are widely used in food, beverages, and cigarettes. In the packaging of medicines, household products and other products.

| Alloy | Main alloy components except AL | Typical application |

| 1145 | Si+Fe 0.55 ; Cu 0.05; Mn 0.05 ; Mg 0.05 ; Zn 0.1 | Cable foil, pharmaceutical foil, industrial foil |

| 1200 | Si+Fe 1.0 ; Cu 0.05; Mn 0.05 ; Zn 0.1 | Hose foil |

| 1235 | Si+Fe 0.65 ; Cu 0.05; Mn 0.05 ; Mg 0.05 ; Zn 0.1 | Pharmaceutical Composite Foil |

| 8011 | Si 0.5~0.9 ; Fe 0.6~1.0 ; Cu 0.1 ; Mn 0.2 ; Mg 0.1 ; Cr 0.1 ; Zn 0.1 | Tobacco foil, flexible packaging foil, heat sealing foil, medicinal foil, industrial insulation board foil |

| 8021 | Si 0.15 ; Fe 1.2~1.7 ; Cu 0.05 | Hose foil, medicinal foil, medicinal composite foil |

| 8079 | Si 0.05~0.3 ; Fe 0.7~1.3 ; Cu 0.05 ; Zn 0.1 | Hose foil, pharmaceutical foil, medicinal composite foil, food flexible packaging foil |

Sealing: The crystal structure of metal provides high barrier properties. For example, aluminum foil has a thickness of 6.3~9µm and is usually used for compounding with materials such as film or paper to achieve better strength and sealing.

Light shielding: Aluminum foil is a solid metal that can block visible light (including ultraviolet light).

Stability: Except for acids and alkalis, it has high stability to most substances.

Non-absorbent: Does not absorb lipids, oils, water and other liquids.

Flexible packaging foil

Hygiene and safety: After the entire production process of aluminum foil is completed, the finished aluminum foil has been sterilized and can be shipped in a sterile state. Aluminum foil is safe for food contact and will not cause bacterial growth.

Food contact: European standard EN602 aluminum foil packaging can contact food, and western aluminum foil is usually used for packaging of food, medicine and cosmetics.

Taste, Smell: Aluminum foil is a tasteless, odorless product.

Recyclable: Aluminum can be recycled without compromising quality. Using modern separation technology, aluminum can be separated and utilized from daily necessities.

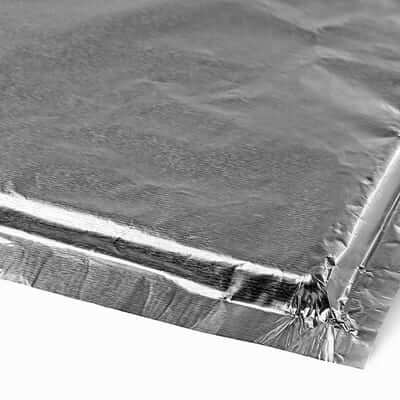

Fully folded: After the aluminum is fully annealed, it returns to a fully soft state and can maintain a good shape after forming.

Plasticity: Aluminum has very good plasticity and can produce large deformations without affecting its barrier properties.

Corrosion resistance: In the natural state, aluminum will form an oxide film under the action of oxygen, which plays a good shielding role. Aluminum is also stable in the range of pH 4-9.

Reflectivity: The reflectivity of radiant heat and light is 98%. The reflectivity of both sides of the aluminum foil is the same.

The production process of flexible packaging aluminum foil usually includes the following key links: blank material selection, aluminum foil rolling, slitting, cleaning and disinfection, etc.

Below we will introduce the specific steps and key points in these links in detail.

The raw materials (blanks) for producing aluminum foil are mainly divided into cast-rolled blanks and hot-rolled blanks. Compared with hot-rolled blanks, the quality of cast-rolled blanks is more difficult to control. Since the deformation of aluminum foil rolled with cast-rolled billets is much smaller, the quality of cast-rolled billets, such as air passages, inclusions, segregation, coarse grains and other defects, have a more direct impact on aluminum foil rolling. The following figure shows different blanks. The crystal image level of the material.

The main rolling equipment for aluminum foil includes: rough rolling mill, intermediate rolling mill, coiler, and finishing mill; decoilers, shears, annealing furnaces, etc. in subsequent processes; and grinders for regular processing and maintenance of the pressure rollers. There are also equipment customized by each manufacturer according to the product varieties and specifications it produces.

Production process of flexible packaging aluminum foil

Aluminum foil calendering production process:

Aluminum foil rough, medium and finish rolling mills are mainly divided according to the thickness range of the product, and their corresponding control modes are different.

Rough rolling: minimum exit thickness: 0.02~0.04mm, mainly based on roll gap position control and post-tension control;

Intermediate rolling: minimum exit thickness: 0.01mm, with tension control as the main focus;

Finish rolling: minimum exit thickness: 0.004.4*2mm, mainly controlled by speed and post-tension;

Slitting: According to the needs, the fine-rolled double aluminum foil is slit into finished aluminum coils of different diameters and widths, generally divided into 3-inch and 6-inch inner diameters;

Quenching: Generally, an electric-heated positive pressure or negative pressure annealing furnace is used, and different annealing temperatures and times are set as needed to recrystallize the aluminum foil to achieve the purpose of removing oil and re-establishing performance.

The rolled aluminum foil is usually larger, which is not conducive to packaging and use. Therefore, slitting is required during the production process. Slitting is the use of professional equipment to cut large pieces of aluminum foil into small pieces of various sizes according to requirements. Precision and efficiency must be paid attention to during the slitting process to ensure the smooth progress of the subsequent production process.

Flexible packaging aluminum foil mainly uses the metallic luster, light barrier, air barrier and certain strength and ductility of aluminum foil. According to different uses, the emphasized performance is also different. Aluminum foil for flexible packaging can be divided into three categories according to the use:

The first category, food and drug packaging, is mainly sealed, mainly emphasizing gas barrier properties, light barrier properties, and non-toxicity. This kind of aluminum foil includes: packaging of medicines and quasi-drugs (medical equipment, medical supplies), 0.02MM, 0.015MM, 0.009MM, 0.007MM.

Flexible packaging aluminum foil application

Food, quasi-food (toothpaste) packaging, 0.015, 0.012, 0.009, 0.007MM.

The second category, decoration, mainly focuses on aesthetics, emphasizing uniform surface gloss. This kind of aluminum foil includes: various printing outer packaging, advertising.

The third category, between the first and second categories, requires both a certain degree of sealing and a certain degree of aesthetics. Mainly cigarettes, alcohol, food packaging.

|

|

|

| Medicine package | Coffee packaging | Food vacuum packaging |

|

|

|

| Tissue packaging | Food packaging | Jam packaging |

Flexible packaging aluminum foil currently has several issues to be resolved.

● The uniformity of the surface condition of flexible packaging aluminum foil is too expensive. If a good surface is required, the production cost will increase significantly. So far, there is no good solution.

● As a product of extreme thickness, aluminum foil almost exhausts all its plasticity. The reworkability of flexible packaging aluminum foil is not high, despite the use of new alloys and processes, (eg: 8011, 8079). There is still no good way to significantly improve plasticity. However, the method of flexible packaging compound bag-making processing has less consideration for this aspect, so that bursting often occurs.

● The index for measuring the plasticity of aluminum foil is unscientific and cannot truly express the plasticity of aluminum foil. The performance of flexible packaging aluminum foil is still in the trial stage. Without scientific indicator measurement, production inspection cannot be carried out.

● Scientific selection of thickness, reasonable composite technology, and supporting materials are as important as the performance of the aluminum foil itself. Reasonable matching can not only stabilize product quality but also reduce costs.

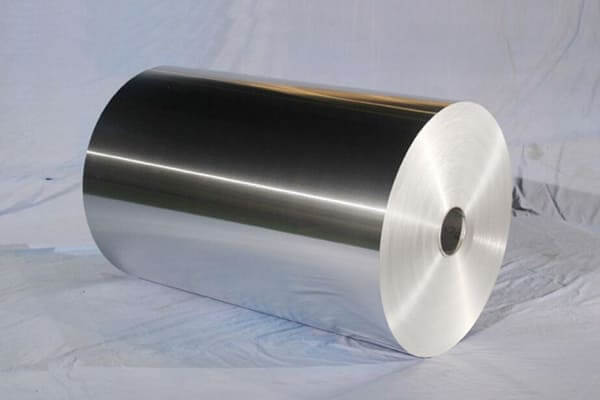

As a manufacturer with more than 20 years of experience in aluminum foil production, Huawei Aluminum provides high-quality aluminum foil in various alloys. The following are the flexible packaging aluminum foils we often provide:

8011 O flexible packaging aluminum foil

Alloy: 1100 aluminum foil, 1235 aluminum foil, 8011 aluminum foil, 8021 aluminum foil, 8079 aluminum foil

Thickness: 0.005mm – 0.020mm

Width: Maximum 1850mm

ID: 3″ (76mm) or 6″ (152mm)

Common applications: vacuum packaging bags, cigarette packaging, Tetra Pak packaging, food packaging bags, insulation materials, retort bags, etc.

Electronic aluminum foil is a kind of aluminum foil processed by a series of rolling, cleaning and cutting processes of high-purity aluminum ingots. It is a key raw material for the production of aluminum electrolytic capacitors.

3105 Aluminum Sheet is adding some other elements on the basis of pure aluminum, such as cu, mg, si, mn, etc., the purpose is to improve the strength of aluminum alloy

5000 series aluminum alloy is an Al-Mg alloy series with high strength and excellent corrosion resistance. It is commonly used in the manufacturing of marine, oil tanks, ships, automobile, building materials and other fields.

Aircraft grade aluminum sheet is a type of aluminum alloy that is specifically designed for use in aerospace applications. These sheets are made from high-strength aluminum alloys that are lightweight yet strong enough to withstand the stresses and strains of flight.

Aluminum alloy 8011 aluminum foil is widely used in aluminum-plastic composite board base tape and food packaging. As a professional aluminum foil 8011 manufacturer in China, Huawei Aluminum has a large 8011 aluminum foil production base and has accumulated more than 20 years of rich aluminum foil production experience and skilled processing technology.

Factory hot selling thick aluminum foil, thin aluminum foil, household packaging aluminum foil, food packaging foil, medicinal aluminum foil

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Hello, I am interested in 3*1500*3500 mm 5754 H111 Checkered Aluminium Plate - Diamond Shape Powermaster Ltd. Moscow, Volokolamskoe shosse 1, str. 1, of. 19, Moscow, 125080

Buenos días, Me interesaría saber el costo de Paneles de nido de abeja de aluminio para usar como refuerzo interior de bandejas, estantes , mesadas que realizamos en acero inoxidable AISI 304. De espesor del panel de 10 y 20 mm, con la piel superior e inferior de aluminio espesor 0.8 mm liso o cepillado o solo el núcleo del nido de abeja de aluminio; con tamaño de celda de 10 o 15 mm ( o estándar ) . tamaño de las planchas de 1500 x 3000 mm o la lo que recomiende para el uso que le quiero dar. Desde ya muchas gracias

Proszę o ofertę na blachę aluminiową grubość 20 mm, w gatunku 1060. 8000 kg

Dear Sirs, I'm looking for a provider of aluminum 7075-T651 in 1.0 or 1.5 mm thickness. We need about 180 plates of 200 mm x 200 mm. Are you able to provide a quote and delivery time for this? Thank you so much in advance. Kind regards, Francisco Silva

Hello, I hope this message meets you well. I have perused your website and I want a detailed price quote for your product; upon your response to this message I will forward more details concerning this order/project to you. I look forward to doing business with you. Warm thanks. Best regards, Ahmet Emir Purchase Manager SER MEKATRONIK SANAYI VE TICARET LTD.STI. Turkgucu O.S.B. Mahallesi 216.Sokak NO:5/1 Corlu / Tekirdag / Turkey Email: [email protected]