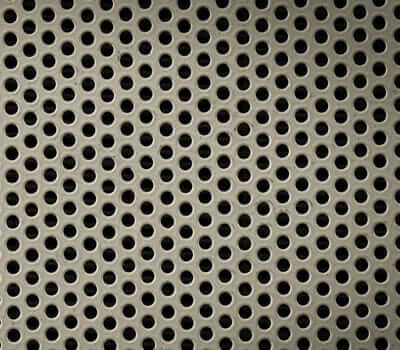

Perforated aluminum sheets are made by aluminum sheets that have been machined with round holes (or other designs). The holes can be in line or staggered to increase the number of openings.

Perforated aluminum sheet is the use of a CNC punch or CNC engraving machine to punch or drill holes of different shapes and sizes in an aluminum sheet to combine different shapes and provide aesthetic appeal.

Perforated aluminum sheets are made by aluminum sheets that have been machined with round holes (or other designs). The holes can be in line or staggered to increase the number of openings.

Aluminum is a lightweight, high-performance alloy and is the most commonly used material when making perforated metal. It is easier to manufacture and offers higher ductility than perforated steel and stainless steel sheets.

Perforated Aluminum Sheet

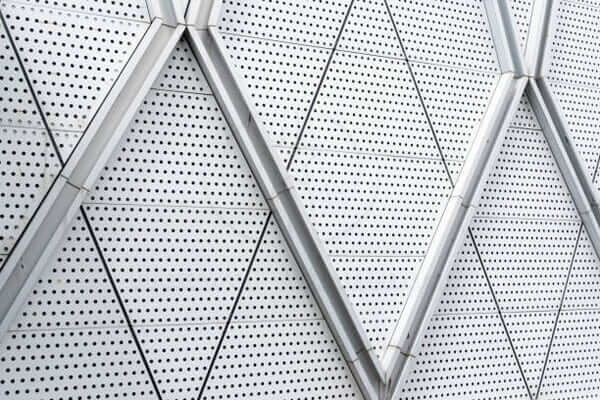

Aluminum perforated panels bring a modern design element to architectural designs and are durable.

Material grade: aluminum, 1050/1060/1070/3003/5005/6061 aluminum, etc.

Available hole types: round, square, slotted, hexagonal, any decorative pattern or text.

Available Finishes: Original, Powder Coated, Fluorocarbon Coated, Anodized.

Thickness range: 0.5mm – 4mm.

The oxide layer formed by the reaction of perforated aluminum sheet with the atmosphere, perforated aluminum has strong corrosion resistance. Compared to metals such as steel, nickel, brass, and copper, it is a relatively light metal and fairly ductile.

It is available in a variety of surface finishes and is highly reflective to heat and light. For most applications, perforated aluminum sheet does not require a protective coating, but is usually anodized to improve color and strength.

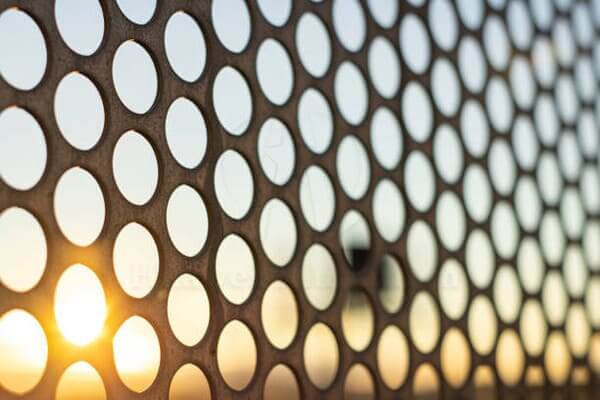

Perforated Aluminum Sheet For Audio

Aluminum perforated sheets are very useful at low temperatures. At sub-zero temperatures, it increases in strength while maintaining ductility. Aluminum alloy sheets lose some of their strength when the temperature exceeds 400 degrees Fahrenheit.

Is there a lightweight durable and decorative metal product with holes of various sizes? That’s aluminum perforated sheet.

Whether your project requires perforations for enhanced aesthetics, drainage, light control, acoustic elements or privacy applications, aluminum perforated panels combine high-end design and functionality for interior and exterior designs.

Decorative Perforated Aluminum Sheet

Perforated aluminum panels have been standard in many commercial developments for some time now. Besides adding a design element to a building, there are many other benefits of using perforated aluminum panels. They are also becoming increasingly popular in residential development and construction.

The standard size of perforated aluminum sheet provided by Warwick Aluminium is 2440mm x 1220mm, and custom sheets with borders are also available. There are many different designs, from standard round holes to diamonds, crosses, squares and more. We accept custom stamped aluminum sheets of any size, thickness, alloy and pass.

We offer aluminum perforated sheets in a variety of sizes, thicknesses, alloys and hole patterns, the most common is 4×8 aluminum sheet, the following is the size table of our stock perforated aluminum sheet.

| Width | Length | Thickness | Hole Diameter | Pitch Center to Center |

| 4′ (1,219mm) | 8′ (2,438mm) | 0.7mm | 3mm | 5mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 1.0mm | 1.5mm | 2.5mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 1.0mm | 3mm | 5mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 1.0mm | 4mm | 7mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 1.2mm | 3mm | 5mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 1.2mm | 4mm | 7mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 1.2mm | 6mm | 10mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 1.2mm | 8mm | 12mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 1.2mm | 10mm | 15mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 1.5mm | 3mm | 5mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 1.5mm | 6mm | 10mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 1.5mm | 8mm | 12mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 1.5mm | 10mm | 15mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 1.5mm | 12mm | 18mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 2.0mm | 3mm | 5mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 2.0mm | 6mm | 10mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 2.0mm | 8mm | 12mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 2.0mm | 10mm | 15mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 2.0mm | 15mm | 21mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 2.0mm | 20mm | 30mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 3.0mm | 3mm | 5mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 3.0mm | 6mm | 10mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 3.0mm | 10mm | 15mm |

| 4′ (1,219mm) | 8′ (2,438mm) | 3.0mm | 12mm | 18mm |

Aluminum perforated sheets are available in full and cut sizes in a variety of applications. Stamped aluminum sheet features include:

Advantages of perforated aluminum sheet

Perforated aluminium sheet reduce weight and reduce the passage of light, liquids, sound and air while providing a decorative or decorative effect. Perforated aluminum panels are corrosion resistant and are commonly used in interior and exterior design, HVAC, noise control, sunscreens, building exteriors, ceilings, furniture, shielding and fencing.

Perforated Aluminum Sheet Ceiling

3003 aluminum alloy is the most widely used of all aluminum alloys.

Aluminum Perforated Sheet 3003 is a 3003 aluminum alloy metal sheet that has been stamped with a pattern.

It is basically commercial pure aluminum with the addition of manganese, which increases the strength by about 20% over 1100.

Aluminum Perforated Sheet 3003

It has all the properties of 3003 alloy aluminum sheet, it has excellent corrosion resistance and machinability, it can be deep drawn or spun, welded or brazed.

Discover the benefits of 5052 H32 aluminum checkered plates. Lightweight, corrosion-resistant, and anti-slip design ideal for flooring, ramps, vehicles, and marine projects.

3A21 aluminum plate is an Al-Mn series aluminum alloy, which belongs to the weldable LF21 aluminum alloy and is known for its excellent anti-rust properties.

Learn how non-stick aluminum foil works, its high-performance coatings, heat resistance, and benefits in food safety and sustainability. A must-read guide for chefs and manufacturers.

Discover premium PVDF color coated aluminium sheets with excellent durability, UV resistance, and vibrant color retention. Perfect for architectural, industrial, and decorative applications.

3105 Aluminum Sheet is adding some other elements on the basis of pure aluminum, such as cu, mg, si, mn, etc., the purpose is to improve the strength of aluminum alloy

Aluminum foil is one of the components of power capacitor equipment. The addition of aluminum foil material can not only improve the quality of the capacitor, but also increase the voltage resistance of the capacitor while ensuring the performance and life of the capacitor.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

I am planning a business trip to China and I am very interested in your aluminium 8011 products for food container production. I would like to visit your factory during my stay in china: See your production lines (foil rolling, annealing, slitting, packing). Discuss specifications (8011-O temper, thickness 0.05–0.08 mm, jumbo roll). Review your quality certificates and export experience. Could you please let me know: Your available dates for a visit The location of your factory If you can provide an invitation letter for my business visa (M visa). Thank you for your kind support. Looking forward to your reply. Best regard: LOUNIS MUSTAPHA company name:TOP BARQUETTE SELECT [email protected] what's up:213 770 91 69 43

Merhaba ; Burak ÜNAL ben. Antalya ' da Ambalaj ve Temizlik ürünleri tedarik eden bir firmanın yetkilisiyim. Ayrıca P.E Streç aktarım işi yapmaktayım. Makinalarımızı 9 ve 10 micron alüminyum folyo aktarımına uyacak şekilde revize edeceğiz. Sizden istediğim, 9 veya 10 micron olacak şekilde 35 cm ve 45 cm jumbo folyolar için fiyat, termin ve şu bilgileri istiyorum ; 35 cm jumbo folyonun ortalama ağırlığı. 45 cm jumbo folyonun ortalama ağırlığı. Deneme olacağı için bu 2 ölçüde minimum sipariş tonajımız ne kadar olması gereklidir. İyi çalışmalar.

We are A Commercial Lighting 's parts and accessories Manufacturer in egypt below is our current requirements for production process from aluminum coil (Alloy 1050 temper O thickness 0.3 mm width 25cm=10tons width 29.5cm=6tons width 33.5cm=5tons width 37 cm=5tons kindly send us your best quotation ASAP according to our company below details: Below is our company details : Full legal company name: Focused ligth for industrial investment ., Co address: Plot no 8 - extension of 4th industrial - zone sadat - minofia - egypt Telephone number Ahmed nseem +201016644789 & +201010879400 Eng Moh El shrief : Mob : +2 01016644789 Tax ID number : 699-483-174

I am writing to inquire about the products that your company offers. I am particularly interested in the product listed below: *Aluminum Coil QTY-20 Units Could you please provide me with more information on these products, including pricing, availability, and any additional details that may be relevant? and also quote your ordinary unit price for supplying these product, together with your discount price for the volume purchase of full truck load. Note: Additionally to the above, our standard Payment Terms:Net 15days to 30 days from the date of supply with the supplier's Invoice.

Bonjour, Je souhaiterait savoir si vous faites des feuilles aluminium de grande taille ? dimension souhaiter: 2500mm X 8000mm pour 0,3 épaisseur . je suis un particulier et vivant en France pour la livraison. merci a vous d'avance Cordialement Mr NEVEU