Flexibilní obalová hliníková fólie je tenká fólie vyrobená z hliníku, která se běžně používá při balení potravin a farmaceutických obalů. Na rozdíl od tvrdé hliníkové fólie, flexibilní obalová hliníková fólie je měkká a dokáže se přizpůsobit různým tvarům nádob, takže je široce používán pro balení potravin a léků.

Flexibilní obalová hliníková fólie je tenká fólie vyrobená z hliníku, která se běžně používá při balení potravin a farmaceutických obalů. Na rozdíl od tvrdé hliníkové fólie, flexibilní obalová hliníková fólie je měkká a dokáže se přizpůsobit různým tvarům nádob, takže je široce používán pro balení potravin a léků.

Flexibilní balení hliníkové fólie se vyznačuje dobrou vzduchotěsností a odolností proti vodě, které mohou chránit jídlo a léky před vnikáním kyslíku a těkavou vlhkostí, čímž se prodlužuje čerstvost potravy a životnost léků. Navíc, flexibilní obalová hliníková fólie má také odolnost proti korozi a stínění proti světlu, které mohou zabránit korozi potravin a léků fotooxidací a zachovat jejich původní kvalitu.

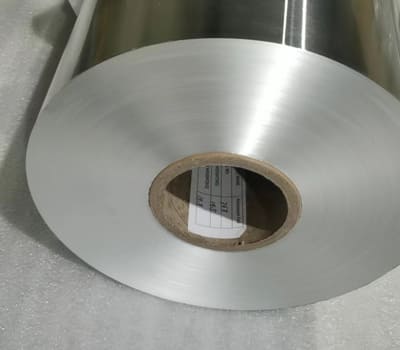

flexibilní balení hliníkovou fólie

Další výhodou flexibilní obalové hliníkové fólie je, že se snadno přenáší a otevírá, který je pro spotřebitele vhodný k použití. Ve stejnou dobu, flexibilní obalová hliníková fólie může také tisknout různé vzory a znaky, což může zvýšit estetiku produktu a hodnotu značky.

Ve zkratce, flexibilní obalová hliníková fólie je vysoce kvalitní potravinářský a farmaceutický obalový materiál, který má výhody vzduchotěsnosti, voděodolnost, odolnost proti korozi a zastínění světla, které mohou chránit čerstvost a kvalitu produktů, a zároveň usnadnit používání spotřebitelů a zvýšit estetiku produktů.

Typy slitin hliníkové fólie vybrané pro flexibilní obaly jsou převážně 1000 série a 8000 série. Z hlediska kompozice, 1000 série obsahuje více jiných slitinových komponent než 8000 série. Proto, z hlediska zpracovatelnosti hliníkové fólie na flexibilní obaly, výkon 8000 série hliníková fólie bude lepší.

Je lepší a má lepší zpracovatelnost než 1000 série. Mezi nimi, 8011, 8021, a 8079 hliníkové fólie jsou klíčovými produkty společnosti 8000 série hliníkových fólií. S jejich vynikajícím těsněním, plasticity, a odolnost proti korozi, jsou široce používány v potravinářství, nápoje, a cigarety. V balení léků, výrobky pro domácnost a další výrobky.

| Slitina | Hlavní slitinové komponenty kromě AL | Typická aplikace |

| 1145 | Ano + Víra 0.55 ; Cu 0.05; Mn 0.05 ; Mg 0.05 ; Zn 0.1 | Kabelová fólie, farmaceutická fólie, průmyslová fólie |

| 1200 | Ano + Víra 1.0 ; Cu 0.05; Mn 0.05 ; Zn 0.1 | Hadicová fólie |

| 1235 | Ano + Víra 0.65 ; Cu 0.05; Mn 0.05 ; Mg 0.05 ; Zn 0.1 | Farmaceutická kompozitní fólie |

| 8011 | A 0,5~0,9 ; Fe 0,6~1,0 ; Cu 0.1 ; Mn 0.2 ; Mg 0.1 ; Cr 0.1 ; Zn 0.1 | Tabáková fólie, flexibilní balicí fólie, tepelně svařovací fólie, léčivá fólie, průmyslová izolační deska fólie |

| 8021 | A 0.15 ; Fe 1,2~1,7 ; Cu 0.05 | Hadicová fólie, léčivá fólie, léčivá kompozitní fólie |

| 8079 | A 0,05 ~ 0,3 ; Fe 0,7 ~ 1,3 ; Cu 0.05 ; Zn 0.1 | Hadicová fólie, farmaceutická fólie, léčivá kompozitní fólie, Flexibilní balení potravin |

Utěsnění: Krystalová struktura kovu poskytuje vysoké bariérové vlastnosti. Například, Hliníková fólie má tloušťku 6,3 ~ 9 um a obvykle se používá pro kombinování materiálů, jako je film nebo papír, k dosažení lepší síly a těsnění.

Světelné stínění: Hliníková fólie je pevný kov, který může blokovat viditelné světlo (včetně ultrafialového světla).

Stabilita: S výjimkou kyselin a alkaliků, má vysokou stabilitu pro většinu látek.

Neabsorbent: Neabsorbuje lipidy, oleje, voda a další kapaliny.

Flexibilní balicí fólie

Hygiena a bezpečnost: Po dokončení celého výrobního procesu hliníkové fólie, Hotová hliníková fólie byla sterilizována a může být dodávána ve sterilním stavu. Hliníková fólie je bezpečná pro kontakt s potravinami a nezpůsobí růst bakterií.

Kontakt s jídlem: Evropský standard EN602 Hliníková fólie může kontaktovat jídlo, a západní hliníková fólie se obvykle používá pro balení potravin, lék a kosmetika.

Chuť, Vůně: Hliníková fólie je bez chuti, produkt bez zápachu.

Recyklovatelné: Hliník lze recyklovat bez ohrožení kvality. Použití moderní technologie separace, hliník lze oddělit a využívat od denních potřeb.

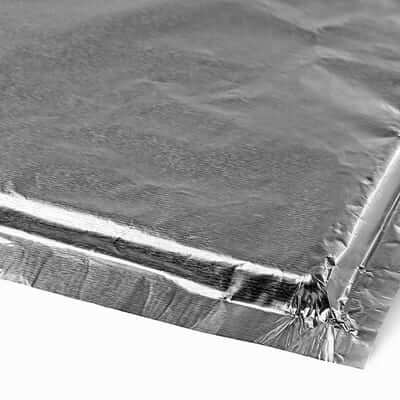

Plně složené: Po plně žíhání hliníku, Vrátí se do plně měkkého stavu a po vytvoření si může udržovat dobrý tvar.

Plastičnost: Hliník má velmi dobrou plasticitu a může produkovat velké deformace, aniž by to ovlivnilo jeho bariérové vlastnosti.

Odolnost proti korozi: V přirozeném stavu, hliník vytvoří oxidový film pod působením kyslíku, který hraje dobrou roli stínění. Hliník je také stabilní v rozsahu pH 4-9.

Odrazivost: Odrazivost sálavého tepla a světla je 98%. Odrazivost obou stran hliníkové fólie je stejná.

Proces výroby flexibilního balení hliníkové fólie obvykle zahrnuje následující klíčové odkazy: Výběr prázdného materiálu, Hliníková fólie válcování, rozřezání, Čištění a dezinfekce, atd.

Níže uvedeme konkrétní kroky a klíčové body v těchto odkazech podrobně.

Suroviny (mezery) Pro produkci hliníkové fólie jsou převážně rozděleny na mezery s válcovanými a horkými mezerami. Ve srovnání s mezerami válcovanými horkými, Kvalita litiovaných polotovarů je obtížnější ovládat. Vzhledem k tomu, že deformace hliníkové fólie válcovaná s odlitými sochy je mnohem menší, Kvalita obsazených sochorů, například vzduchové pasáže, inkluze, segregace, hrubá zrna a další vady, mít přímější dopad na válcování hliníkové fólie. Následující obrázek ukazuje různé mezery. Úroveň krystalického obrazu materiálu.

Hlavní válcovací zařízení pro hliníkovou fólii zahrnuje: hrubý válcovací mlýn, meziprodukt, Coiler, a dokončovací mlýn; Decoilers, Náží, žíhací pece, atd. v následujících procesech; a brusky pro pravidelné zpracování a údržbu tlakových válců. K dispozici je také vybavení přizpůsobené každým výrobcem podle odrůd produktu a specifikací, které vytváří.

Proces výrobního procesu flexibilního balení hliníkové fólie

Proces výrobního procesu kalendářství hliníku:

Hliníková fólie drsná, Střední a povrchové válcovací mlýny jsou rozděleny hlavně podle rozsahu tloušťky produktu, a jejich odpovídající řídicí režimy se liší.

Hrubé válcování: minimální tloušťka výstupu: 0.02~ 0,04 mm, Hlavně na základě kontroly polohy mezery a řízení po napětí;

Přechodné válcování: minimální tloušťka výstupu: 0.01mm, s ovládáním napětí jako hlavním zaměřením;

Dokončete válcování: minimální tloušťka výstupu: 0.004.4*2mm, hlavně řízená rychlostí a přídavným napětím;

Řezání: Podle potřeb, jemně válcovaná dvojitá hliníková fólie je rozřezána na hotové hliníkové svitky různých průměrů a šířek, obecně se dělí na vnitřní průměry 3 palce a 6 palců;

Kalení: Obvykle, používá se elektricky vyhřívaná přetlaková nebo podtlaková žíhací pec, a různé teploty a časy žíhání jsou nastaveny podle potřeby k rekrystalizaci hliníkové fólie, aby se dosáhlo účelu odstranění oleje a obnovení výkonu.

Srolovaná hliníková fólie bývá větší, což není vhodné pro balení a použití. Proto, řezání je nutné během výrobního procesu. Sliting je použití profesionálního vybavení k snížení velkých kusů hliníkové fólie na malé kousky různých velikostí podle požadavků. Přesnost a efektivita musí být věnována pozornost během procesu rozřezání, aby se zajistil hladký pokrok následujícího výrobního procesu.

Flexibilní balení hliníkové fólie používá hlavně kovový lesk, Světelná bariéra, Letecká bariéra a určitá síla a tažnost hliníkové fólie. Podle různého použití, zdůrazněný výkon je také odlišný. Hliníková fólie pro flexibilní obaly lze rozdělit do tří kategorií podle použití:

První kategorie, Balení potravin a drog, je hlavně uzavřen, hlavně zdůrazňování vlastností plynové bariéry, Světelné bariérové vlastnosti, a netoxicita. Tento druh hliníkové fólie zahrnuje: Balení léků a kvazi-drog (lékařské vybavení, zdravotnické potřeby), 0.02MM, 0.015MM, 0.009MM, 0.007MM.

Flexibilní použití hliníkové fólie

Jídlo, téměř jídlo (zubní pasta) obal, 0.015, 0.012, 0.009, 0.007MM.

Druhá kategorie, dekorace, Zaměřuje se hlavně na estetiku, zdůrazňování jednotného povrchového lesku. Tento druh hliníkové fólie zahrnuje: Různé vnější obaly tisku, inzerce.

Třetí kategorie, mezi první a druhou kategorií, Vyžaduje jak určitý stupeň těsnění, tak určitý stupeň estetiky. Hlavně cigarety, alkohol, balení potravin.

|

|

|

| Balíček medicíny | Balení kávy | Balení potravin |

|

|

|

| Tkáňové obaly | Balení potravin | Balení jam |

Flexibilní balení hliníkové fólie má v současné době několik problémů, které mají být vyřešeny.

● Uniformita povrchového stavu flexibilního balení hliníkové fólie je příliš drahá. Pokud je vyžadován dobrý povrch, Výrobní náklady se výrazně zvýší. Dosud, neexistuje dobré řešení.

● Jako produkt extrémní tloušťky, hliníková fólie téměř vyčerpává veškerou svou plasticitu. Přepracovatelnost flexibilního balení hliníkové fólie není vysoká, Navzdory použití nových slitin a procesů, (např: 8011, 8079). Stále neexistuje dobrý způsob, jak výrazně zlepšit plasticitu. nicméně, Metoda zpracování flexibilních obalů složených pytlů má pro tento aspekt menší pozornost, takže k prasknutí často dochází.

● Index pro měření plasticity hliníkové fólie je nevědecký a nemůže pravdivě vyjádřit plasticitu hliníkové fólie. Výkon flexibilní obalové hliníkové fólie je stále ve zkušební fázi. Bez vědeckého měření indikátorů, nelze provést kontrolu výroby.

● Vědecký výběr tloušťky, rozumné kompozitní technologie, a podpůrné materiály jsou stejně důležité jako výkon samotné hliníkové fólie. Rozumné sladění může nejen stabilizovat kvalitu produktu, ale také snížit náklady.

Jako výrobce s více než 20 letité zkušenosti s výrobou hliníkových fólií, Huawei Aluminium poskytuje vysoce kvalitní hliníkovou fólii v různých slitinách. Následují flexibilní obalové hliníkové fólie, které často poskytujeme:

8011 O Flexibilní balení hliníkové fólie

Slitina: 1100 hliníková fólie, 1235 hliníková fólie, 8011 hliníková fólie, 8021 hliníková fólie, 8079 hliníková fólie

Tloušťka: 0.005mm - 0,020 mm

Šířka: Maximálně 1850 mm

ID: 3″ (76mm) nebo 6 ″ (152mm)

Běžné aplikace: vakuové balení, balení cigaret, Tetra Pak Packaging, Tašky na obaly potravin, Izolační materiály, Pentort tašky, atd.

Hliníková fólie je jednou ze součástí zařízení výkonových kondenzátorů. Přidání materiálu hliníkové fólie může nejen zlepšit kvalitu kondenzátoru, ale také zvýšit napěťový odpor kondenzátoru a zároveň zajistit výkon a životnost kondenzátoru.

Elektronická hliníková fólie je druh hliníkové fólie zpracované sérií válcování, procesy čištění a řezání vysoce čistých hliníkových ingotů. Je klíčovou surovinou pro výrobu hliníkových elektrolytických kondenzátorů.

Tenký hliníkový plech obvykle označuje plochý kus hliníkového materiálu, který má tloušťku menší než 6 mm (0.24 palce).

6016 Hliníková deska je součástí 6000 řady slitin hliníku, které jsou primárně známé pro jejich vynikající odolnost proti korozi, dobrá svařitelnost, a snadnost formovatelnosti.

Běžný hliníkový kruhový kotouč pro lampy je 1050-O, 1060-Ó, 1100-Ó, atd., protože stínidlo se získává lisováním hliníkových disků, a hliníkové disky ve stavu O mají lepší tažnost a jsou vhodnější pro lisování;

Prozkoumejte jedinečné vlastnosti, výrobní proces, a rozsáhlé aplikace 1060 hliníková fólie. Zjistěte, proč je tato slitina s vysokou čistotou nezbytnou v balení, elektronika, HVAC, a více.

č.52, Dongming Road, Zhengzhou, Henan, Čína

Henan Huawei Aluminium Co., Ltd, Jeden z největších dodavatelů hliníku v Číně Henan,Jsme založena v roce 2001 a máme bohaté zkušenosti s dovozem a vývozem a vysoce kvalitními hliníkovými výrobky

Po – So, 8AM – 17:00

Neděle: ZAVŘENO

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Nejnovější komentáře

Ahoj, mě zajímá 3*1500*3500 mm 5754 H111 Checkered Aluminium Plate - Diamond Shape Powermaster Ltd. Moskva, Volokolamskoe dálnice 1, str. 1, z. 19, Moskva, 125080

Dobré ráno, Me interesaría saber el costo de Paneles de nido de abeja de aluminio para usar como refuerzo interior de bandejas, police na knihy , pracovní desky, které vyrábíme z nerezové oceli AISI 304. tloušťka panelu 10 y 20 mm, con la piel superior e inferior de aluminio espesor 0.8 mm hladké nebo kartáčované nebo pouze hliníkové voštinové jádro; s velikostí buňky 10 Ó 15 mm ( nebo standardní ) . velikost desek 1500 X 3000 mm nebo co mi doporučíte pro použití, které to chci dát. Předem moc děkuji

Prosím o nabídku na hliníkový plech tl 20 mm, v žánru 1060. 8000 kg

Vážení, Hledám dodavatele hliníku 7075-T651 in 1.0 nebo 1.5 tloušťka mm. Potřebujeme asi 180 desky z 200 mm x 200 mm. Jste schopni poskytnout cenovou nabídku a dodací lhůtu pro toto? Předem moc děkuji. S pozdravem, Francisco Silva

Ahoj, Doufám, že vás tato zpráva dobře potká. Prohlédl jsem si vaše webové stránky a chci podrobnou cenovou nabídku na váš produkt; po vaší odpovědi na tuto zprávu vám předám další podrobnosti týkající se této objednávky/projektu. Těším se na spolupráci s vámi. Vřelé díky. S pozdravem, Ahmet Emir Purchase Manager SER MEKATRONIK SANAYI VE TICARET LTD.STI. Turkgucu O.S.B. Mahallesi 216.Sokak NO:5/1 Kudrnatý / Tekirdag / Turkey Email: [email protected]