Lembaran aluminium anodisasi adalah lembaran aluminium yang ditempatkan dalam elektrolit yang sesuai (seperti asam sulfat, asam kromat, asam oksalat, dll.) sebagai anoda, dan elektrolisis dilakukan dalam kondisi tertentu dan pengaruh arus eksternal.

Lembaran aluminium anodisasi adalah lembaran aluminium yang ditempatkan dalam elektrolit yang sesuai (seperti asam sulfat, asam kromat, asam oksalat, dll.) sebagai anoda, dan elektrolisis dilakukan dalam kondisi tertentu dan pengaruh arus eksternal. Film oksida padat terbentuk pada permukaan lembaran aluminium, dan sifat film anodisasi yang tidak berwarna dan berpori digunakan untuk mewarnai dan melindungi matriks aluminium.

Lembaran aluminium anodisasi

Lapisan tipis aluminium oksida terbentuk pada permukaan lembaran aluminium yang teroksidasi, dengan ketebalan 5 ke 20 mikron, dan film anodisasi yang keras dapat dijangkau 60 ke 200 mikron.

Akhirnya, itu mengakibatkan aluminium menjadi lebih keras daripada berlian. Ini biasanya digunakan di lingkungan yang keras atau aplikasi yang memerlukan paparan terhadap elemen. Prosesnya menciptakan lapisan keras yang menggantikan bahan aslinya. Plus, itu tidak akan mengelupas seperti karat biasa, jadi lembaran aluminium oksida dapat digunakan dalam banyak aplikasi.

5052 lembaran aluminium memiliki kinerja anodisasi yang baik, dan perbedaan warna setelah anodisasi kecil.

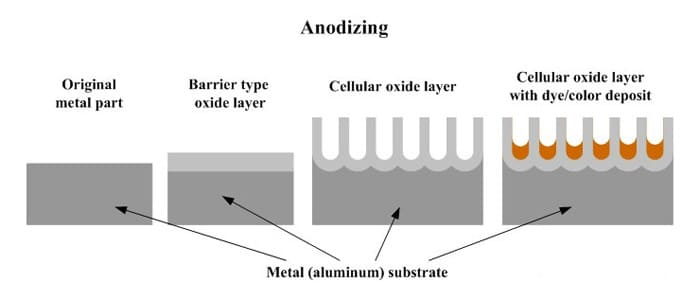

Anodisasi dilakukan dengan merendam aluminium ke dalam bak elektrolit asam dan mengalirkan arus listrik melalui medium. Katoda dipasang di bagian dalam tangki anodisasi; aluminium bertindak sebagai anoda, sehingga ion oksigen dilepaskan dari elektrolit untuk bergabung dengan atom aluminium pada permukaan bagian yang dianodisasi. Anodisasi adalah, Karena itu, masalah oksidasi yang sangat terkontrol—peningkatan fenomena yang terjadi secara alami.

Proses anodisasi lembar aluminium

Pembersihan → perlakuan awal → elektrolit → arus dan waktu → anodisasi → penyegelan → pembersihan dan pengeringan

Pembersihan: Sebelum dianodisasi, bagian logam perlu dibersihkan untuk menghilangkan lemak dan kotoran di permukaan. Proses pembersihan biasanya dilakukan dengan larutan basa atau asam.

Pretreatment: Bagian logam terlebih dahulu menjalani beberapa perlakuan awal, seperti deburring, penggilingan atau pemolesan. Hal ini dapat meningkatkan permukaan akhir setelah anodisasi sampai batas tertentu.

Elektrolit: Bagian logam ditempatkan dalam elektrolit yang mengandung zat pengoksidasi dan bahan tambahan lainnya. Komposisi elektrolit tergantung pada logam yang digunakan dan perlakuan permukaan yang diinginkan.

Saat Ini dan Waktu: Buat bagian logam menjadi anodik dengan menambahkan arus searah ke elektrolit. Arus dan waktu perawatan disesuaikan dengan efek perawatan yang diinginkan.

Anodisasi: Dalam elektrolit, film oksida terbentuk pada permukaan bagian logam. Proses ini disebut anodisasi. Selama proses ini, ketebalan dan warna film oksida bergantung pada elektrolit dan parameter arus/waktu yang digunakan.

Penyegelan: Dengan cara merendamnya dalam air panas atau bahan penutup lainnya, mikropori film oksida disegel, sehingga meningkatkan ketahanan terhadap korosi dan kekerasan.

Pembersihan dan pengeringan: Bagian yang diproses perlu dibersihkan dan dikeringkan untuk menghilangkan kelebihan elektrolit dan sealant.

| Ketebalan film oksida | Oksidasi kimia: lapisan oksidanya tipis, dengan ketebalan sekitar 0.5 ke 4 mikron. Oksidasi elektrokimia: ketebalan film oksida sekitar 5 ke 20 mikron. Anodisasi keras: ketebalan film oksida dapat mencapai 60 ke 200 mikron. |

| Kekerasan film oksida | Sangat sulit: HV=1200-1500 Paduan aluminium: HV=400-800 |

| Tahan panas | Dibandingkan dengan sebelum oksidasi, kinerja ketahanan suhu tinggi sangat meningkat |

| Titik leleh film oksida | Hingga 2320K |

| Konduktivitas | Isolasi yang sangat baik, tegangan tembus 2000V |

| Tahan korosi | Bagus sekali, ketahanan korosi selama ribuan jam dalam semprotan garam ω=0,03NaCl |

| Adhesi | Perpaduannya dengan bodi sangat kuat |

| Apakah itu beracun | Ramah lingkungan dan tidak beracun, itu dapat menggantikan baja tahan karat dan proses penyemprotan dan pelapisan listrik tradisional |

| Tahan panas | Dapat menahan suhu sekitar 1500°C, sedangkan plat alumunium biasa hanya mampu bertahan pada suhu 660°C. |

| Aplikasi | Bahan abrasif dan alat pemotong, bagian aluminium yang membutuhkan ketahanan panas tinggi dan kinerja isolasi, seperti piston, silinder, bantalan, impeler peralatan pembangkit listrik tenaga air, dll.. |

Lembaran logam aluminium anodized merupakan jenis lembaran aluminium yang telah mengalami proses anodisasi. Anodisasi adalah proses elektrokimia yang mengentalkan lapisan oksida alami pada permukaan aluminium, membuatnya lebih tahan lama, tahan korosi, dan mampu menahan warna dan pewarna. Berikut adalah beberapa fitur utama dan kegunaan lembaran logam aluminium anodized:

Peningkatan Ketahanan Korosi: Aluminium anodized memiliki lapisan oksida yang lebih tebal dan stabil pada permukaannya, yang memberikan ketahanan yang sangat baik terhadap korosi dan oksidasi. Hal ini membuatnya cocok untuk aplikasi luar ruangan dan laut.

Peningkatan Daya Tahan: Proses anodisasi mengeraskan permukaan aluminium, menjadikannya lebih tahan gores dan tahan lama. Hal ini membuatnya cocok untuk aplikasi di mana material mungkin mengalami keausan.

Pilihan Warna: Aluminium anodisasi dapat diwarnai dalam berbagai warna selama proses anodisasi. Hal ini memungkinkan adanya berbagai pilihan warna untuk tujuan dekoratif dan estetika.

Insulasi listrik: Aluminium anodized memiliki sifat isolasi listrik yang baik, yang dapat bermanfaat dalam aplikasi tertentu di mana konduktivitas listrik perlu diminimalkan.

Penggunaan Dekoratif dan Arsitektur: Aluminium anodized umumnya digunakan dalam elemen arsitektur, seperti fasad bangunan, dinding tirai, dan hiasan dekoratif, karena daya tahan dan daya tarik estetika.

Produk konsumer: Hal ini juga digunakan dalam produksi produk konsumen seperti peralatan masak, peralatan, dan penutup elektronik, dimana daya tahan dan ketahanannya terhadap pewarnaan adalah penting.

Ringan: Aluminium sendiri merupakan bahan yang ringan, dan aluminium anodized mempertahankan sifat ini, sehingga cocok untuk aplikasi yang mengutamakan bobot.

Aplikasi Lembar Aluminium Anodized

Perawatan Mudah: Aluminium anodized relatif mudah dibersihkan dan dirawat, membutuhkan prosedur pembersihan sederhana untuk mempertahankan penampilannya.

Tidak Beracun dan Ramah Lingkungan: Anodisasi adalah proses yang tidak beracun, dan aluminium anodized dinilai ramah lingkungan karena awet dan tahan lama, mengurangi kebutuhan akan penggantian yang sering.

Aluminium anodized untuk bangunan

Harga

Harganya mahal. Karena proses yang rumit dan persyaratan teknis yang tinggi, harga lembaran aluminium anodized jauh lebih tinggi dibandingkan dengan lembaran aluminium mill finish.

Masalah perbedaan warna

Masalah perbedaan warna pada lembaran aluminium anodized bukan disebabkan oleh teknologi produksi karena cairan penangas oksidasi dibuat dari berbagai unsur kimia.. Setiap kali sekumpulan bahan aluminium teroksidasi, komposisi kimia dalam cairan mandi berubah, sehingga cairan mandi teroksidasi dan diwarnai dengan nilai yang bervariasi. Bahan alumunium selalu mempunyai perbedaan warna.

Lembaran cermin aluminium anodisasi PVD adalah proses di mana lapisan tipis material diendapkan ke permukaan aluminium melalui proses pengendapan vakum..

Panel sarang lebah aluminium adalah jenis material komposit yang terinspirasi oleh struktur sarang lebah heksagonal yang ditemukan di alam. Panel ini terkenal dengan bobotnya yang ringan, kekuatan tinggi, dan fleksibilitas, menjadikannya pilihan populer di berbagai industri, dari konstruksi hingga luar angkasa.

Kita 3003 Produk aluminium foil telah diekspor ke Australia, Maroko, Suriah, Kuwait, Turki, Arab Saudi, UEA, Irak, Yordania, Jerman, Polandia, Spanyol, Brazil, dll.. Kami dengan tulus menyambut Anda untuk mengunjungi pabrik kami.

3000 paduan aluminium seri adalah paduan AL-MG yang komponen utamanya adalah aluminium, mangan dan sejumlah kecil unsur lainnya. Ia memiliki sifat yang sangat baik seperti ketahanan korosi yang baik, kemampuan proses dan kemampuan las.

Itu 1000 Pelat Aluminium Cermin Gulung Seri adalah produk aluminium dengan kemurnian tinggi dengan permukaan akhir luar biasa yang memberikan tampilan seperti cermin.

Lingkaran aluminium untuk peralatan masak biasanya mengacu pada potongan atau lingkaran berbentuk lingkaran yang terbuat dari aluminium yang digunakan dalam pembuatan berbagai jenis peralatan masak., seperti pot, Panci, dan peralatan memasak.

No.52, Jalan Dongming, Zhengzhou, Henan, Cina

Henan Huawei Aluminium Co, Ltd, Salah Satu Pemasok Aluminium Terbesar Di Cina Henan,Kami Didirikan Pada Tahun 2001, Dan Kami Memiliki pengalaman yang kaya dalam impor dan ekspor dan produk aluminium berkualitas tinggi

Senin – Sabtu, 8PAGI – 5 sore

Minggu: Tertutup

© Hak Cipta © 2023 Henan Huawei Aluminium Co., Ltd

Komentar Terbaru

Tuan-tuan yang terhormat, Saya mencari penyedia alumunium 7075-T651 in 1.0 atau 1.5 ketebalan mm. Kami membutuhkan tentang 180 piring dari 200 mm x 200 mm. Apakah Anda dapat memberikan penawaran dan waktu pengiriman untuk ini? Terima kasih banyak sebelumnya. Salam baik, Francisco Silva

Halo, Saya harap pesan ini dapat diterima dengan baik oleh Anda. Saya telah membaca dengan teliti situs web Anda dan saya ingin penawaran harga terperinci untuk produk Anda; atas tanggapan Anda terhadap pesan ini, saya akan meneruskan rincian lebih lanjut mengenai pesanan/proyek ini kepada Anda. Saya berharap dapat berbisnis dengan Anda. Terima kasih yang hangat. Salam, Ahmet Emir Purchase Manager SER MEKATRONIK SANAYI VE TICARET LTD.STI. Turkgucu O.S.B. Mahallesi 216.Sokak NO:5/1 Keriting / Tekirdag / Turkey Email: [email protected]

Saya butuh kutipan untuk 3000 Seri Seri Aluminium/Gulungan (3104 H19) untuk tuna bisa produksi, Finishing-grade makanan, Pengiriman ke Mazzatlan, Meksiko.

Saya merencanakan perjalanan bisnis ke China dan saya sangat tertarik dengan aluminium Anda 8011 Produk untuk produksi wadah makanan. Saya ingin mengunjungi pabrik Anda selama saya tinggal di China: Lihat Jalur Produksi Anda (gulungan kertas timah, anil, menggorok, sedang mengemas). Diskusikan spesifikasi (8011-Wahai amarah, ketebalan 0,05-0,08 mm, Jumbo Roll). Tinjau Sertifikat Kualitas Anda dan Pengalaman Ekspor. Bisakah Anda memberi tahu saya: Your available dates for a visit The location of your factory If you can provide an invitation letter for my business visa (M visa). Terima kasih atas dukungan baik Anda. Menantikan balasan Anda. Hormati Terbaik: LOUNIS MUSTAPHA company name:TOP BARQUETTE SELECT [email protected] what's up:213 770 91 69 43

Halo ; Burak ünal i. Saya seorang pejabat perusahaan yang memasok produk pengemasan dan pembersih di Antalya. Saya juga melakukan pekerjaan transfer peregangan P.E. Mesin kami 9 ve 10 Kami akan merevisi transfer foil aluminium mikron. Apa yang saya inginkan dari Anda, 9 atau 10 mikron 35 cm dan 45 CM Jumbo Fooys Harga untuk Fooy, Termin dan saya ingin informasi berikut ; 35 Berat rata -rata cm jumbo foil. 45 Berat rata -rata cm jumbo foil. Ini karena itu akan menjadi persidangan 2 Berapa tonase pesanan minimum kami. Nikmati pekerjaan Anda.