5052 En 6061 aluminum alloy are aluminum alloy products that have received great attention in industry and construction because of their excellent performance and wide range of applications.

Compare 5052 aluminum alloy and 6061 aluminium profiel. Not only do they have a lot in common, even 5052 aluminum alloy and 6061 aluminum alloy can be replaced with each other in certain specific usage scenarios, but they also have many differences. We will compare 5052 aluminum in detail below. alloy and 6061 aluminium profiel.

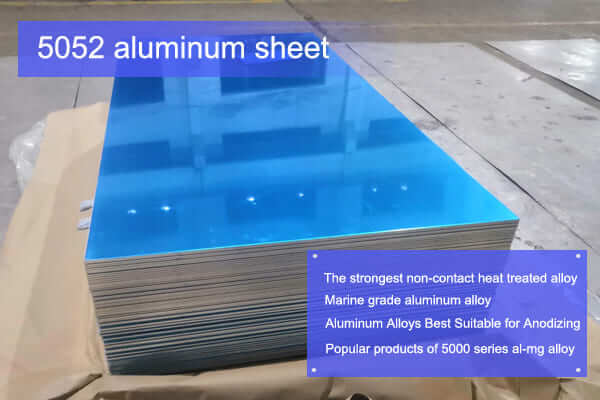

5052 aluminiumlegering behoort tot de 5000 serie legeringen. The main added element is magnesium, over 3-5%, which is called aluminum-magnesium alloy.

5052 aluminum also happens to be the strongest non-heat treatable sheet and plate commonly used.

De dichtheid van 5052 aluminum alloy is 2.68g/cm3, which is slightly lower than pure aluminum, so it is very commonly used in the aerospace field, such as aircraft fuel tanks.

5052 Aluminium profiel

5052 aluminum alloy does not contain any copper, so its resistance to salt water corrosion is higher than other aluminum alloys, making 5052 aluminum plate a perfect choice for boat building.

5052 aluminum alloy is very suitable for anodizing because its color change is very small after anodizing.

The main elements added to the 6000 series aluminum alloy are magnesium and silicon, en de 6061 aluminum alloy is its representative product. It has the characteristics of medium strength, goede corrosiebestendigheid, lasbaarheid, no deformation after processing, easy coloring, en goed oxidatie-effect.

6061 aluminum is widely used in various industrial structural parts that require a certain strength and high corrosion resistance, such as mobile phone slots, mobile phone casings, manufacturing trucks, tower buildings, structural materials, schepen, railway vehicles, precision machining, enz.

6061 Aluminium

| Element | Samenstelling (%) | |

| 5052 Legering | 6061 Legering | |

| En | 0.25 | 0.4-0.8 |

| Fe | 0.4 | 0.7 |

| Cu | 0.1 | 0.15-0.4 |

| Mn | 0.1 | 0.15 |

| mgr | 2.2-2.8 | 0.8-1.2 |

| Cr | 0.15-0.35 | 0.04-0.35 |

| In | – | – |

| Zn | 0.1 | 0.25 |

| Van | – | 0.15 |

| Anderen:Elk | 0.05 | 0.05 |

| Anderen:Totaal | 0.15 | 0.15 |

| Aluminumin | Rest | Rest |

Beide 5052 En 6061 alloys have strong corrosion resistance, but due to the higher mg content in the 5052 legering, 5052 has stronger corrosion resistance and is more suitable for use in the ocean.

|

Material properties |

Type 6061 Aluminium profiel |

Type 5052 Aluminium profiel |

||

|

Units |

Metriek |

Engels |

Metriek |

Engels |

|

Opbrengststerkte |

276 MPa |

40000 psi |

193 MPa |

28000 psi |

|

Elasticiteitsmodulus |

68.9 GPa |

10000 ksi |

70.3 GPa |

10200 ksi |

|

Vermoeidheid Sterkte |

96.5 MPa |

14000 psi |

117 MPa |

17000 psi |

|

Warmtegeleiding |

167 W/m-K |

1160 BTU-in/hr-ft²-°F |

138 W/m-K |

960 BTU-in/hr-ft²-°F |

|

Bewerkbaarheid |

Goed |

Arm |

The yield strength of a material is the minimum amount of stress that will cause a test piece to change shape, or permanently deform.

6061 is more difficult to permanently deform than 5052 (276 MPa VS. 193 MPa), which means that 6061 has higher strength. On the other hand, it also shows that the machining performance of 6061 aluminum alloy will be somewhat lacking.

De kracht van 6061 is hoger dan die van 5052 under the same condition (the zn and cr content of 6061 alloy is higher than that of 5052).

The modulus of elasticity can be thought of as the “stiffness” of an alloy; it is a measure of how much a material resists plastic deformation. Materials with higher moduli are considered more elastic because it takes more work to permanently deform the material.

Most metals are good conductors of heat, and these alloys are no different. The thermal conductivity of a metal describes how much heat can move through a material, and is useful in thermal components such as heat sinks and heat exchangers. 6061 aluminum has a higher thermal conductivity than 5052 aluminium, making it the preferred choice for heat dissipation applications.

6061 aluminum machines well because it is more brittle, meaning smaller bits of the alloy (called “chips” in machine shops) fracture off more easily when machined. 5052 aluminum is more difficult to machine, as its elastic nature causes larger chips which cause excessive wear on tooling and less precise cuts. Dus, terwijl 5052 aluminum is the premier material for welded sheet work, 6061 aluminum shines as a tough machining alloy.

| Legering | 5052 | 6061 |

| Woedeaanval | F,O,H12,H14,H16,H18,H19,H22,H24,H26,H28,H32,H34,H36,H38,H111,H112,H114 | F,O,T4,T451,T42,T5,T6,T651,T6511,H112 |

Het belangrijkste verschil tussen 5052 aluminum sheet and 6061 aluminum sheet is:

5052 aluminium plaat kan niet worden versterkt door warmtebehandeling, which means that 5052 aluminum alloy can be strengthened by cold working or strain hardening (such as rolling or forging). 5052 H112 aluminum sheet and 5052 H32 aluminum sheet are the most common hardening processes.

Maar 6061 aluminum plate can be heat treated. It will be heated in a submerged furnace at 533 °C (990°F) and then water quenched. 6061 T4 aluminum alloy and 6061 T6 aluminum alloy are the most common forms of 6061 and are often used in heavy-duty structures. Daarom, strength and formability under T tempering are very important.

Vanwege zijn uitstekende prestaties, 5052 aluminum alloy has strong corrosion resistance, hoge sterkte-gewichtsverhouding, excellent tensile strength, verlenging, enz. Daarom, 5052 aluminum alloy is widely used in the marine industry and electronics industry. and chemical applications.

Toepassing van 5052 Aluminium

6061 aluminum alloy is also known as “structural aluminum”. It is one of the commonly used extruded aluminum profiles. Thanks to its formability, it can be formed into sheets, rounds, squares, extrusions, rolling or any form.

The uses of Huawei Aluminum 6061 aluminum alloy mainly include the following aspects:

6061 Aluminum Alloy Applications

In terms of aluminum alloy prices, there is not much price difference between 5052 En 6061. Echter, due to the complex and more difficult processing technology of 6061 aluminium profiel, the price will be slightly higher than that of 5052 aluminium profiel.

Huawei-aluminium Aluminum Plate Price Structure

De 1000 serie aluminiumplaat is een serie pure aluminiumplaten. De samenstelling is voornamelijk aluminium, met een inhoud van meer dan 99%.

5005 aluminium spoel verwijst naar de 5005 aluminiumplaat nadat deze is gegoten en gewalst en vervolgens door trekken en buigen tot een spoelvorm is verwerkt,

Corrosiebestendige zwarte aluminiumfolie te koop, China Aluminiumfolie Fabrikant Lage prijspromotie, Kleur gecoate aluminiumfolie geanodiseerde folie grondstoffenleverancier

De 3003 aluminium strip is gemaakt van 3003 aluminium legering. De 3 serie aluminiumlegering wordt ook wel een aluminium-mangaanlegering genoemd.

5×10 aluminiumplaat is een gebruikelijke specificatie van aluminiumplaat geproduceerd door fabrikanten van aluminiumplaten,het is 5 voet breed en 10 voet lang.

3105 Aluminium Sheet voegt nog enkele andere elementen toe op basis van puur aluminium, zoals cu, mg, En, mn, enz., het doel is om de sterkte van aluminiumlegeringen te verbeteren

Nr.52, Dongming-weg, Zhengzhou, Henan, China

Henan Huawei Aluminium Co., Ltd, Een van de grootste aluminiumleveranciers in China Henan,We zijn opgericht in 2001 en hebben een rijke ervaring in import en export en hoogwaardige aluminiumproducten

Ma – Za, 8AM – 17.00 uur

Zondag: Gesloten

© Auteursrecht © 2023 Henan Huawei Aluminium Co., Ltd

laatste Reacties

Geachte heer, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99,50% MIN) MAAT:450 X32 X6MM. JOUW EEN 570 NL-AW 1050 A, AANTAL=3400KG

Hallo, Zou u zo vriendelijk willen zijn om het item als volgt aan te bieden: Spoel 0,6х1250 (1000)mm EN AW-3105 5tons

Hallo, Kunt u mij aluminiumplaten aanbieden?? Eigenlijk heb ik het nodig: 110mm x 1700 mm x 1700 mm 5083 H111 - 21 pcs Next year planed is 177 stuks

Geweldig artikel. Ik was blij verrast, dat ik dit artikel heb gevonden. Veel mensen denken van wel, dat zij over betrouwbare kennis over dit onderwerp beschikken, maar dit is vaak niet het geval. Vandaar mijn aangename verrassing. ik ben onder de indruk. Ik zal deze plek zeker aanbevelen en vaker terugkomen, om nieuwe dingen te zien.

eis van aluminium strip