Aluminum alloy welding is a process that involves joining two or more pieces of aluminum together through the use of heat and a filler material. This method of welding has become increasingly popular in a variety of industries due to the numerous advantages it offers.

Aluminum alloys are widely used in various industries due to their excellent properties such as light weight, Grote sterkte, superior malleability, goede corrosiebestendigheid, and high thermal conductivity. Echter, welding aluminum alloys can be challenging due to their unique metallurgical properties.

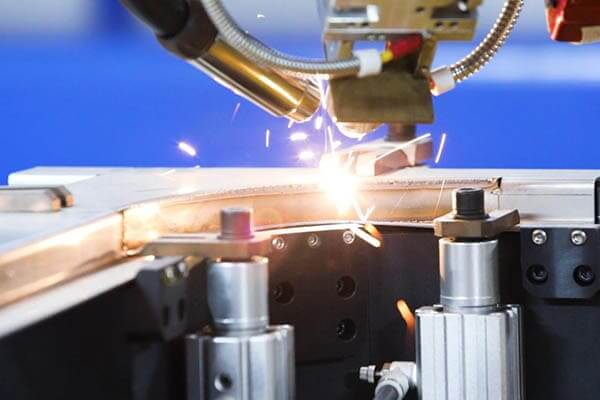

Lassen van aluminiumlegeringen

Aluminum has a high thermal conductivity and low melting point, which can lead to distortion and burn-through during welding. Aluminum also forms an oxide layer when exposed to air. This oxide layer has a much higher melting point than aluminum, which can cause issues during welding.

There are several welding techniques suitable for aluminum alloys:

Aluminum alloy welding is a process that involves joining two or more pieces of aluminum together through the use of heat and a filler material. This method of welding has become increasingly popular in a variety of industries due to the numerous advantages it offers. In this essay, we will explore some of the key benefits of aluminum alloy welding.

One of the main advantages of aluminum alloy welding is its lightweight nature. Aluminium is een lichtgewicht metaal, making it ideal for applications where weight is a concern. By using aluminum alloy welding, manufacturers can create strong and durable structures without adding unnecessary weight. This is particularly important in industries such as aerospace, automobiel, and marine, where weight reduction can lead to increased fuel efficiency and improved performance.

Another advantage of aluminum alloy welding is its high strength-to-weight ratio. Aluminum alloys are known for their excellent strength properties, allowing them to withstand heavy loads and harsh environments. By welding aluminum alloys together, manufacturers can create structures that are both lightweight and strong, making them ideal for a wide range of applications.

Furthermore, aluminum alloy welding offers excellent corrosion resistance. Aluminium is van nature bestand tegen corrosie, making it a popular choice for outdoor and marine applications. By welding aluminum alloys together, manufacturers can create structures that are highly resistant to rust and corrosion, ensuring their longevity and durability.

In addition to its lightweight nature, hoge sterkte-gewichtsverhouding, en corrosiebestendigheid, aluminum alloy welding also offers excellent thermal conductivity. Aluminum is a good conductor of heat, allowing for efficient heat transfer during the welding process. This results in faster welding speeds and reduced distortion, leading to higher productivity and cost savings.

Bovendien, aluminum alloy welding is known for its aesthetic appeal. Aluminum alloys can be easily shaped and formed into intricate designs, making them ideal for applications where aesthetics are important. By welding aluminum alloys together, manufacturers can create visually appealing structures that are both functional and attractive.

Ten slotte, aluminum alloy welding offers a wide range of advantages that make it a popular choice in various industries. From its lightweight nature and high strength-to-weight ratio to its corrosion resistance and aesthetic appeal, aluminum alloy welding provides numerous benefits that can improve the performance and longevity of structures. As technology continues to advance, the demand for aluminum alloy welding is expected to grow, making it an essential process for manufacturers looking to create strong, lichtgewicht, and durable structures.

Aluminum alloy welding process

The latest advancements in welding technology for aluminum alloys include:

Please note that the choice of welding technology depends on the specific requirements of the task, including the type of aluminum alloy, the thickness of the material, and the desired properties of the weld. Always consult with a welding professional or refer to the appropriate welding codes and standards for your specific application.

According to TWI Global, some of the precautions you should take when welding aluminum and its alloys are:

Use good shielding practices and parent material/consumable cleanliness to avoid contamination and porosity in the welds.

Select the proper filler metal and welding parameters to minimize the risk of hot cracking, which is a common defect in aluminum welding.

Consider using solid state welding processes such as friction stir welding, which can join aluminum alloys that are difficult to fusion weld.

Aanvullend, Chief Technology suggests some safety measures for aluminum welding, zoals:

Wear protective clothing to shield yourself from potential hazards, such as sparks, spatter, and radiation.

Ensure sufficient ventilation to remove potentially harmful gases, fumes, and smoke, especially ozone, which is produced by the ultraviolet radiation from welding and can cause respiratory issues.

Use appropriate eye and face protection, such as a welding helmet with a suitable shade level, to prevent eye damage and flash burns.

Meer: https://www.alufoil.cn/blog/aluminum-welding-a-practical-guide.html

Aluminium cirkel voor verkeersborden verwijst naar de aluminium cirkel die wordt gebruikt bij de productie van verkeersborden. Omdat aluminiumcirkels een sterke corrosieweerstand en weersbestendigheid hebben, aluminium cirkels zijn zeer geschikt voor de productie van verkeersborden.

De 1000 serie aluminiumplaat is een serie pure aluminiumplaten. De samenstelling is voornamelijk aluminium, met een inhoud van meer dan 99%.

5×10 aluminiumplaat is een gebruikelijke specificatie van aluminiumplaat geproduceerd door fabrikanten van aluminiumplaten,het is 5 voet breed en 10 voet lang.

3003 aluminium vliesgevelplaat is de buitenmuur van een gebouw. Het is een lichtgewicht muur van grote hoogbouw en heeft een zekere decoratieve werking.

5005 aluminium spoel verwijst naar de 5005 aluminiumplaat nadat deze is gegoten en gewalst en vervolgens door trekken en buigen tot een spoelvorm is verwerkt,

1100 Aluminium Coil is de legering met de hoogste commerciële zuiverheid van alle aluminiumkwaliteiten, met een aluminiumgehalte (massafractie) van 99.00%. De sterkte ervan is relatief laag, en het heeft een uitstekende ductiliteit, vervormbaarheid, lasbaarheid, en corrosiebestendigheid.

Nr.52, Dongming-weg, Zhengzhou, Henan, China

Henan Huawei Aluminium Co., Ltd, Een van de grootste aluminiumleveranciers in China Henan,We zijn opgericht in 2001 en hebben een rijke ervaring in import en export en hoogwaardige aluminiumproducten

Ma – Za, 8AM – 17.00 uur

Zondag: Gesloten

© Auteursrecht © 2023 Henan Huawei Aluminium Co., Ltd

laatste Reacties

Geachte heer, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99,50% MIN) MAAT:450 X32 X6MM. JOUW EEN 570 NL-AW 1050 A, AANTAL=3400KG

Hallo, Zou u zo vriendelijk willen zijn om het item als volgt aan te bieden: Spoel 0,6х1250 (1000)mm EN AW-3105 5tons

Hallo, Kunt u mij aluminiumplaten aanbieden?? Eigenlijk heb ik het nodig: 110mm x 1700 mm x 1700 mm 5083 H111 - 21 pcs Next year planed is 177 stuks

Geweldig artikel. Ik was blij verrast, dat ik dit artikel heb gevonden. Veel mensen denken van wel, dat zij over betrouwbare kennis over dit onderwerp beschikken, maar dit is vaak niet het geval. Vandaar mijn aangename verrassing. ik ben onder de indruk. Ik zal deze plek zeker aanbevelen en vaker terugkomen, om nieuwe dingen te zien.

eis van aluminium strip