の製造工程 5052 aluminum alloy is: melting and casting → ingot sawing and milling → billet heating → hot rolling → cold rolling → finished product annealing → cross cutting → packaging.

5052-H32 aluminum alloy

On-line double rotor degassing, then use Al5TiB in the chute to refine the grain, and finally filter through the ceramic filter plate, enter the crystallizer and cast into a flat ingot of 630mm×1400mm×8000mm.

The ingot is cut off by a sawing machine, and then enters the milling machine for peeling, removing the surface segregation layer and oxide scale, and then transfers to the heating furnace for heating. Heating process system: 480 ° C for 3 時間, after the heat preservation is completed, it is taken out of the furnace and rolled.

The high-temperature ingot undergoes 19 passes of hot rough rolling to become an intermediate billet. After cutting the material head, it enters the 4-stand hot finish rolling mill. After continuous rolling and thinning, high-temperature coiling begins to control the hot-rolled coil The thickness is 6.7mm, the final rolling temperature is 325°C±5°C, and the coil is naturally cooled after it is off the machine.

The cooled hot-rolled coils are rolled out of the finished products one by one on the cold rolling mill, and the total processing rate of cold rolling is 25%. 加えて, the cold rolling mill must control the angle and air pressure of the edge purge to prevent oil and splash on the surface of the coil, so as to reduce the risk of oil spot defects.

For direct annealing without cleaning, it is first necessary to ensure that there are no oil spots on the surface of the coil, and it is also necessary to ensure that the residual oil can be completely volatilized, and the process window is very narrow. If the temperature is too low, there will be no oil spots, but there will be residual oil; if the temperature is too high, there will be no residual oil, but there will be oil spots.

The special annealing process system adopted:

In the first stage, the furnace gas is set to 180°C, the heating rate is set to 35°C/h, and the negative pressure and purging are turned on to play the role of pre-drying in the air environment;

In the second stage, when the furnace gas reaches 180°C, start filling N2 gas to control the oxygen content in the furnace below 0.1%, and then keep it warm for 6 hours to play the role of pre-drying in an oxygen-free environment. Will cause oil spots due to oxidation;

In the third stage, the furnace gas is changed to 235°C, and the heating rate is set to 30°C/h. When the temperature of the coil reaches 230°C, it is kept for 3 時間, and the quenching and tempering of the coil is completed, and the expected mechanical properties are achieved. 現時点では, the residual oil is also volatilized, but it has not entered the dangerous temperature range of oil spots (245 ° C ~ 400 ℃);

In the fourth stage, the furnace gas is set to 0°C, and the side cooling fan is started to quickly cool down. When the metal temperature drops below 150°C, it is out of the furnace and exposed to air.

| そして | 鉄 | 銅 | ん | マグネシウム | Cr | の | アル |

| 0.1 | 0.2~0.3 | 0.05 | 0.08 | 2.5~2.7 | 0.18~0.24 | 0.01~0.03 | 残り |

1) そして in the alloy is an impurity element. During casting and solidification, it can form complex ternary compounds with Fe and Al. The primary phase has a large size and is distributed on the dendrite boundary. It is an insoluble phase during the melting process, which is harmful to the plasticity of the alloy . Strict control of w(そして)≤0.10% in the test can reduce the overall amount of AlFeSi complex ternary compounds, thereby improving the plasticity of the alloy.

2) 鉄 in the alloy is not all impurity elements, and its mass fraction is controlled at 0.2% に 0.3%, which can avoid its harmful effects and play its beneficial role. Part of the Fe element in the alloy exists in a supersaturated form. During the homogenization process at high temperature, the AlFeSi dispersed phase can be precipitated inside the grain, and its size is very small, which can refine the recrystallized grain and contribute to the strength and plasticity.

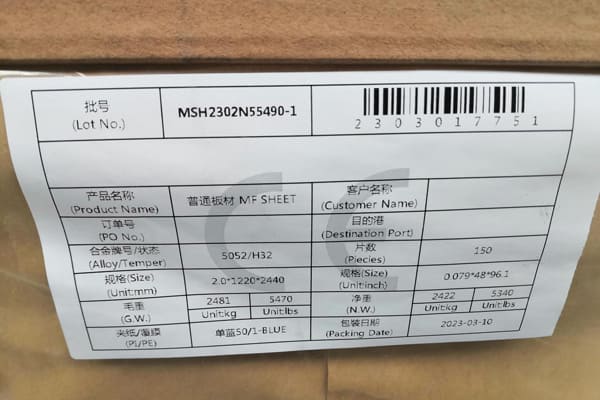

Packaged 5052-H32 aluminum sheet

3) In the alloy, w(鉄)/w(そして)>2.0 is controlled, and the α phase (AlFeSi) and a small amount of β phase (AlFeSi) are mainly formed during solidification, and the morphology of the α phase is bone-like. It can be fully broken during the rolling process and is harmless to plasticity. The β phase (AlFeSi) is a needle-like hard and brittle phase, which is difficult to break during hot rolling and is harmful to plasticity.

4) 銅 in the alloy is an impurity element, which has an impact on the corrosion resistance of the alloy. The w(銅) is controlled to be no more than 0.05%.

5) ん in the alloy is an impurity element. のために 5052 アルミニウム合金, Cr is used to refine the recrystallized grains, not Mn, so w(ん) should be controlled within 0.08%.

6) マグネシウム in the alloy is an alloying element, and Mg is dissolved in the aluminum matrix, which can hinder the movement of dislocations and play a role in work hardening. Controlling w(マグネシウム) で 2.5% に 2.7% can ensure a faster work hardening effect, and sufficient tensile strength can be guaranteed without a large cold working rate.

7) Cr in the alloy is an alloying element. It exists in a supersaturated form when the ingot is solidified, and it precipitates during the subsequent heating process to form a dispersed phase CrAl7. The particles have good thermal stability and can refine the recrystallized grains. It can improve the strength and plasticity of the alloy. Control w(Cr) で 0.18% に 0.24%. If the chromium content is too high, a harmful coarse phase will be formed; if the chromium content is too low, the dispersed phase will be insufficient and the beneficial effect will be weakened.

8) の in the alloy can form TiAl3 and AlTi5B1, which can refine the grains of the ingot, thereby improving the mechanical properties of the ingot.

1) The coil produced by the new process has good surface quality, no oil spots and residual oil, and meets the requirements of the standard. Internal structure observation: the crystal grains are fine and uniform, without fibrous structure. The anisotropy of this organizational state is small, and it is not easy to crack when bent. しかし, the conventional hot-rolled low-temperature directly off-line products are fibrous structures with large anisotropy, and the plates are prone to cracking when they are bent transversely.

2) The mechanical properties and bending test results of the 5.0mm thick 5052-H32 aluminum alloy plate produced by the new process are shown in Table 4. The plates were sent to the end users for trial use. The results were good, and the 90°0t bending did not crack. The new craft products reached the predetermined target requirements.

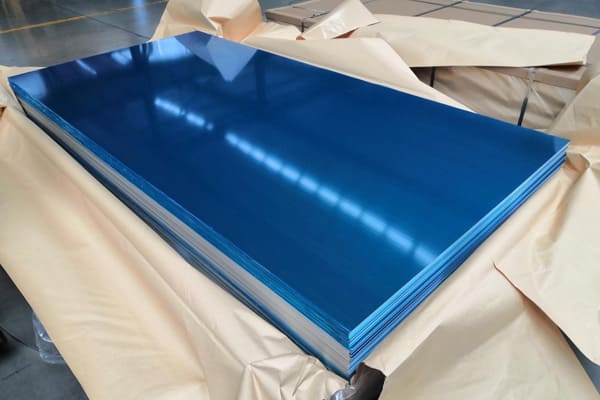

2mm thickness 5052-H32 aluminum sheet

1060 アルミニウムストリップケーブルは優れた耐荷重性を備えています, 特に自立能力. アルミニウム線の長さは次のとおりです。 4000 落ちずに数メートル, 銅ケーブルが到達できるのは 2750 メートル.

ハニカムアルミホイル, アルミニウムハニカムコアとも呼ばれます, 一連の六角形のセルを作成する方法で貼り合わせられた 2 層のアルミニウム箔から作られた一種の軽量コア材料です。, 蜂の巣によく似ています.

私たちの 3003 アルミ箔製品をオーストラリアに輸出しました, モロッコ, シリア, クウェート, 七面鳥, サウジアラビア, アラブ首長国連邦, イラク, ヨルダン, ドイツ, ポーランド, スペイン, ブラジル, 等. 私たちの工場を訪問することを心から歓迎します.

河南華為アルミニウム有限公司, 株式会社, 中国河南省最大のアルミニウムサプライヤーのひとつ,私たちは2001年に設立され、輸出入と高品質のアルミニウム製品の豊富な経験があります

月~土, 8午前 – 午後 5 時

日曜日: 閉まっている

© 著作権© 2023 河南華為アルミニウム有限公司, 株式会社

最新のコメント

拝啓, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% 最小) サイズ:450 X32 X6MM. あなたのもの 570 EN-AW 1050 あ, 数量=3400KG

こんにちは, 以下の商品を提供していただけませんか: コイル 0,6х1250 (1000)mm EN AW-3105 5tons

こんにちは, アルミ板を提供してもらえますか? 実際には必要です: 110mm×1700mm×1700mm 5083 H111 - 21 pcs Next year planed is 177 個

素晴らしい記事. 私は喜んでいました, この記事を見つけたこと. 多くの人がそう思っています, 彼らはこの件に関して信頼できる知識を持っていること, しかし、そうでないこともよくあります. したがって、私の嬉しい驚きは. 私が感銘を受けた. この場所を絶対にお勧めし、もっと頻繁に戻ってきます, 新しいものを見るために.

アルミニウムストリップの要件