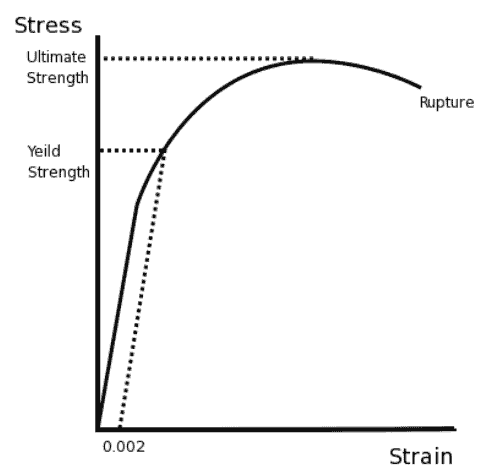

A simplified definition of a fabric’s power is its potential to withstand a positive quantity of load, also known as force or strain, earlier than it reaches specific factors of deformation or strain. A normal way of visualizing this is by the well-known stress-strain curve, proven in the example under.

Stress strain graph aluminum

Those curves are commonly made by means of using a sample of material, which includes aluminum, and making use of tensile pressure to motive deformation up till the factor of rupture. The pressure, and consequently the power of the fabric, is typically measured in gadgets of megapascals (MPa) or kilopounds consistent with square inch (クシ). Deformation is measured as a percent of the authentic length of the sample.

The strength of metallic materials can be measured by several indicators:

抗張力: The maximum force or pressure that a metal material can withstand under tensile stress. Tensile strength is usually expressed in megapascals (MPa).

降伏強さ: The point at which a metallic material begins to plastically deform or flow under tensile stress. It is the ability of a metal material to resist deformation. Yield strength is usually expressed in megapascals (MPa).

伸長: The degree to which a metal material undergoes plastic deformation during stretching. It expresses the percentage by which a material is able to elongate before breaking.

破壊靱性: The ability of a metal material to resist fracture. It is the ability of a material to resist fracture when subjected to stress concentrations.

Aluminum bending test

These indicators reflect the strength and deformation ability of metal materials when they are subjected to external forces. Different metal materials have different strength properties, so when selecting and designing a metal structure or part, the strength of the material needs to be considered to ensure it meets the intended application needs.

The strength of materials can be measured by several common test methods:

Tensile Test: This is one of the most commonly used testing methods to measure the performance of materials under tensile stress. In the tensile test, the standard sample is stretched, and the stress and strain of the sample are measured at the same time, so as to determine the tensile strength, 降伏強さ, 伸長, 等. of the material.

Compression Test: This test method is used to measure the performance of materials under compressive stress. The specimen is compressed while stress and strain are measured to determine the material’s compressive strength and ability to deform.

Bending Test: This test method is used to evaluate the performance of materials under bending loading. The specimen is bent to apply force to measure bending stress and strain and to determine the bending strength and toughness of the material.

Hardness Test: Hardness testing is a quick way to assess the strength of a material. Commonly used hardness testing methods include Brinell Hardness, Rockwell Hardness and Vickers Hardness.

Impact Test: Impact testing is used to evaluate the strength and toughness of materials under impact loads. Commonly used impact test methods include Charpy Test and Izod Test.

Metal after stress strain test

These test methods can provide quantitative data on properties such as strength, deformability, and toughness of materials. Depending on the application needs, it is very important to choose the appropriate test method to evaluate the strength of the material. 同時に, attention should also be paid to factors such as test conditions, standard specifications, and sample preparation to ensure the accuracy and comparability of test results.

Aluminum alloy materials can be divided into low-strength aluminum alloys, medium-strength aluminum alloys and high-strength aluminum alloys according to their strength;

The strength classification is not a strict dividing line, and different aluminum alloy materials can overlap within the strength range. 加えて, the specific composition and heat treatment process of aluminum alloy will also affect its strength characteristics;

The strength of different grades of aluminum alloys is different. 例えば, の強さ 3004 aluminum alloy is much higher than that of 1050, 1060, 1100 and other alloys;

The strength of aluminum alloys of the same grade is also different under different heat treatment states

| 強さ | 3004-○ | 3004-H | 3004-T |

| 抗張力 | 125-165 MPa | 165-215 MPa | 165-205 MPa |

| 降伏強さ | 100-140 MPa | 145-190 MPa | 145-180 MPa |

| 伸長 | 15%-25% | 5%-15% | 10%-20% |

| 硬度 | 30-45 HB | 50-65 HB | 45-55 HB |

Some aluminum alloys have high strength, even comparable to steel. Comparing the strongest aluminum alloy with the same size as steel, steel is generally the strongest.

As an instance, the most tensile energy of one of the normally-determined most powerful aluminum alloys, the AA7068-T6, and one of the strongest metallic alloys, the AISI 1080, are 710MPa and 965MPa, それぞれ. Here you may see a contrast in their Yield energy and remaining Tensile strength.

| Materials | 降伏強さ | Maximum Tensile Strength |

| AA 7068-T6 Aluminum Alloy | 683MPa | 710MPa |

| AISI 1080 鋼鉄 | 585MPa | 965MPa |

When it comes to strength-to-weight ratios, aluminum wins out because it’s only 1/3 the weight of steel with little difference in strength, and it wins when it comes to performance.

When choosing materials, strength is not the only measure, but the strength-to-weight ratio can highlight the performance of materials.

| アルミニウム合金 | Maximum Tensile Strength | アプリケーション |

| 2024 | 465MPa | High-strength structural applications, aircraft fittings, ミサイル部品, ピストン. |

| 5052 | 228MPa | 圧力容器, タンク, architectural uses, 自動車部品, 鉄道車両. |

| 6061 | 310MPa | Truck components, パイプライン, recreation vehicles, 航空機, 自動車部品. |

| 7075 | 572MPa | Highly-stressed structural and aircraft parts, machine parts, ordnance. |

Aluminum alloys for aircraft

反射アルミニウムシートは、反射率が高く、光学分野で広く使用されている金属シートです。, エレクトロニクス, 建設およびその他の分野. この記事ではその原則を紹介します, 反射アルミシートの特徴と用途.

の 6063 アルミニウムシートは、主な合金元素としてマグネシウムとシリコンを含む6000シリーズのアルミニウム合金です。. の強さ 6063 合金はそれよりも低いです 6061 合金, そしてそれは良好な押出性を持っています, 耐食性, 優れた表面処理性能.

5000 シリーズアルミニウム合金は、高強度で耐食性に優れたAl-Mg合金シリーズです。. 船舶の製造によく使用されます, オイルタンク, 船, 自動車, 建材・その他の分野.

河南華為アルミニウム有限公司, 株式会社, 中国河南省最大のアルミニウムサプライヤーのひとつ,私たちは2001年に設立され、輸出入と高品質のアルミニウム製品の豊富な経験があります

月~土, 8午前 – 午後 5 時

日曜日: 閉まっている

© 著作権© 2023 河南華為アルミニウム有限公司, 株式会社

最新のコメント

拝啓, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% 最小) サイズ:450 X32 X6MM. あなたのもの 570 EN-AW 1050 あ, 数量=3400KG

こんにちは, 以下の商品を提供していただけませんか: コイル 0,6х1250 (1000)mm EN AW-3105 5tons

こんにちは, アルミ板を提供してもらえますか? 実際には必要です: 110mm×1700mm×1700mm 5083 H111 - 21 pcs Next year planed is 177 個

素晴らしい記事. 私は喜んでいました, この記事を見つけたこと. 多くの人がそう思っています, 彼らはこの件に関して信頼できる知識を持っていること, しかし、そうでないこともよくあります. したがって、私の嬉しい驚きは. 私が感銘を受けた. この場所を絶対にお勧めし、もっと頻繁に戻ってきます, 新しいものを見るために.

アルミニウムストリップの要件