調質指定システムは、鍛造アルミニウム合金と鋳造アルミニウム合金の両方に使用されます。.

アルミニウム合金を正しく選択するには質別の指定が必要です, その特性は、その組成だけでなく、合金の熱処理や部品の冷間加工にも依存します。.

アルミニウム合金の焼き戻し

アルミニウム合金の調質とは、アルミニウム合金素材を加熱後、室温まで冷却するまでの一定時間高温に保持した状態を指します。, 合金内の構造に特定の変化と調整が加えられるため、. アルミニウム合金の焼き戻し状態は、材料の機械的特性やその他の特性に大きな影響を与える可能性があります。.

アルミニウム合金の焼き戻しパラメータには焼き戻し温度が含まれます, 焼き戻し時間と焼き戻し工程. 焼き戻し温度は合金の組成と特性によって異なります。, 焼き戻し時間と焼き戻しプロセスは、材料の厚さや形状などの要因によって異なります。.

アルミニウム合金の焼き戻しにおいて, 粒子が成長し、粒界が広くなります. 同時に, 内部ストレスの解放により, 硬度などの合金の機械的特性, 強度や靭性も変化します. 加えて, アルミニウム合金の焼き戻し状態は、材料の耐食性や耐摩耗性などの他の特性にも影響します。.

アルミニウム合金の製造・加工工程において, 適切な焼き戻し状態を選択することが非常に重要です. 最適な材料特性を得るには、特定の用途と要件に従って焼き戻し条件を選択する必要があります。.

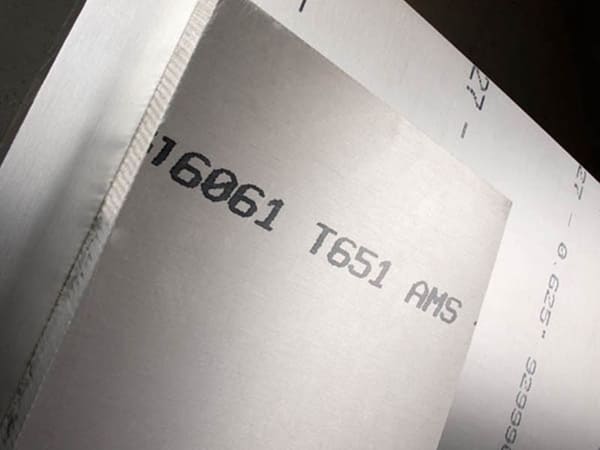

焼き戻し指定システムに使用される接尾辞は、合金指定とハイフンで区切られています。 (例: 2618-T61, 3003-H14, 1100-○, 6061-T6アルミニウム合金).

気質指定システムは文字を使用します, 基本的な気性と数字を決定する, 文字に続いて, 基本的な気性の状態を示す.

焼き戻し指定スキームを図に示します。.

治療 H では 3 桁目を使用できます.

H_ _1 は冷間加工された製品に適用されます (ひずみ硬化) 制御されたH_ _ 焼き戻しに必要な量より少ない.

H112 は、高温での作業により多少の焼き戻しが発生する可能性があり、機械的特性の制限がある製品に適用されます。.

3003 h114アルミニウム合金

トリートメント T1, T2, T5 および T10 は、高温成形プロセスからの冷却から開始します。 (熱間圧延, 鍛造, 押し出しなど). この冷却はあまり速くありません, したがって、この処理は部分的な溶解処理とみなされる場合があります。.

6061 t6アルミシート

治療 T は追加の数字を使用する場合があります (2番, 3番目と4番目).

2桁目 (ゼロではない) 熱処理のバリエーションを示すために T1…T10 に追加される場合があります.

T_51, T_510, T_511 溶体化処理後または高温成形プロセスからの冷却後に行われる延伸による平均応力除去.

T_52 は、溶体化処理後または高温成形プロセスからの冷却後に行われる圧縮による応力除去を意味します。.

T_54 は、仕上げ型の冷間再打撃による型鍛造品の応力除去を意味します。.

T_42, T_62 焼鈍からの平均溶体化処理 (○) または、自然な状態が続く人工的な状態として (T_42) または人工的な (T_62) エージング.

知識の源:アルミニウム合金の調質指定

異なるシリーズのアルミニウム合金の一般的な焼き戻しは異なります, 対応する機械的特性も異なります;

| グループ | 合金 | 共通の気性 &アンプ; 応用 |

| 1000 シリーズ | 1050 1060 1100 |

○: これが焼きなまし調質です, 強度が最も低く、延性が最も高いもの. 良好な成形性が要求される用途によく使用されます。, 屋根や断熱材など.

H12: これは 4 分の 1 の硬さ評価を持つひずみ硬化焼戻しです。. 焼鈍したものより若干強度が高くなります。 (○) 焼き戻しが施され、深絞り加工やスピニング加工によく使用されます。. H14: これは、半分の硬さの評価を持つひずみ硬化焼戻しです。. H12 焼戻しよりも強度が高く、適度な強度と良好な成形性が必要な用途によく使用されます。, 板金成形や溶接など. H16: これは、4 分の 3 の硬さ評価を持つひずみ硬化焼戻しです。. H14 焼戻しよりも強度が高く、より高い強度と良好な成形性が必要な用途によく使用されます。, 屋根や外壁など. H18: これは、フルハード等級のひずみ硬化焼戻しです。. すべてのひずみ硬化焼戻しの中で最高の強度を持ち、高強度と良好な成形性を必要とする用途に一般的に使用されます。, キッチン用品や調理器具など. |

| 3000 シリーズ | 3003 3004 3105 |

○: これが焼きなまし調質です, 強度が最も低く、延性が最も高いもの. 良好な成形性が要求される用途によく使用されます。, 屋根や断熱材など.

H14: これは、半分の硬さの評価を持つひずみ硬化焼戻しです。. 焼鈍したものより強度が高い (○) 焼き戻しが強く、適度な強度と良好な成形性を必要とする用途によく使用されます。, 板金成形や溶接など. H16: これは、4 分の 3 の硬さ評価を持つひずみ硬化焼戻しです。. H14 焼戻しよりも強度が高く、より高い強度と良好な成形性が必要な用途によく使用されます。, 屋根や外壁など. H18: これは、フルハード等級のひずみ硬化焼戻しです。. すべてのひずみ硬化焼戻しの中で最高の強度を持ち、高強度と良好な成形性を必要とする用途に一般的に使用されます。, キッチン用品や調理器具など. H22: これは 4 分の 1 の硬さ評価を持つひずみ硬化焼戻しです。. 焼鈍したものより若干強度が高くなります。 (○) 焼き戻しが施され、深絞り加工やスピニング加工によく使用されます。. |

| 3104 | ○: これが焼きなまし調質です, 強度が最も低く、延性が最も高いもの. 良好な成形性が要求される用途によく使用されます。, 屋根や断熱材など.

H14: これは、半分の硬さの評価を持つひずみ硬化焼戻しです。. 焼鈍したものより強度が高い (○) 焼き戻しが強く、適度な強度と良好な成形性を必要とする用途によく使用されます。, 板金成形や溶接など. H18: これは、フルハード等級のひずみ硬化焼戻しです。. すべてのひずみ硬化焼戻しの中で最高の強度を持ち、高強度と良好な成形性を必要とする用途に一般的に使用されます。, 飲料缶や蓋など. H19: これは、4 分の 3 の硬さ評価を持つひずみ硬化焼戻しです。. H18 焼戻しよりも強度が高く、高強度と良好な成形性が要求される用途によく使用されます。, 飲料缶や蓋など. |

|

| 5000 シリーズ | 5005 5052 |

○: これが焼きなまし調質です, 強度が最も低く、延性が最も高いもの. 良好な成形性が要求される用途によく使用されます。, 屋根や断熱材など.

H32: これはひずみ硬化され安定した焼き戻しで、硬度は 4 分の 1 です。. 焼鈍したものより強度が高い (○) 焼き戻しが強く、適度な強度と良好な成形性を必要とする用途によく使用されます。, 板金成形や溶接など. H34: これはひずみ硬化され、安定した焼き戻しであり、ハーフハード評価です。. H32 焼戻しよりも強度が高く、より高い強度と良好な成形性が必要な用途によく使用されます。, 屋根や外壁など. H36: これはひずみ硬化され安定した焼き戻しであり、4 分の 3 の硬さ評価を備えています。. H34 焼戻しよりも強度が高く、より高い強度と良好な成形性が必要な用途によく使用されます。, トラックやトレーラーのボディパネルなど. H38: これは、フルハード等級のひずみ硬化と安定化が施された焼き戻しです。. すべてのひずみ硬化および安定化焼戻しの中で最高の強度を備えており、高強度と良好な成形性を必要とする用途に一般的に使用されます。, 航空宇宙部品など. |

| 5083 | ○: これが焼きなまし調質です, 強度が最も低く、延性が最も高いもの. 良好な成形性が要求される用途によく使用されます。, タンク車や造船など.

H32: これはひずみ硬化され安定した焼き戻しで、硬度は 4 分の 1 です。. 焼鈍したものより強度が高い (○) 焼き戻しが強く、適度な強度と良好な成形性を必要とする用途によく使用されます。, 海洋および海洋構造物など. H116: これはひずみ硬化され安定した焼き戻しであり、少なくともマグネシウム含有量が 4%. H32焼戻しよりも強度が高く、高強度と優れた耐食性が要求される用途によく使用されます。, 造船や構造用途など. H321: これはひずみ硬化され安定した焼き戻しであり、少なくともマグネシウム含有量が 4%. H116調質よりも強度が高く、高強度と優れた耐食性が要求される用途によく使用されます。, 海洋および海洋構造物など. |

|

| 5754 | ○: これが焼きなまし調質です, 強度が最も低く、延性が最も高いもの. 良好な成形性が要求される用途によく使用されます。, 板金成形や溶接など.

H111: これは、焼鈍したものとほぼ同じ応力除去焼戻しです。 (○) 気性. 良好な成形性と高い耐食性が要求される用途によく使用されます。, 海洋部品など. H22: これはひずみ硬化され安定した焼き戻しで、硬度は 4 分の 1 です。. 焼鈍したものより強度が高い (○) 焼き戻しが強く、適度な強度と良好な成形性を必要とする用途によく使用されます。, 板金成形や溶接など. H32: これはひずみ硬化され安定した焼き戻しで、硬度は 4 分の 1 です。. 焼鈍したものより強度が高い (○) 焼き戻しが強く、適度な強度と良好な成形性を必要とする用途によく使用されます。, 板金成形や溶接など. H34: これはひずみ硬化され、安定した焼き戻しであり、ハーフハード評価です。. H32 焼戻しよりも強度が高く、より高い強度と良好な成形性が必要な用途によく使用されます。, 屋根や外壁など. |

|

| 6000 シリーズ | 6061 | ○: これが焼きなまし調質です, 強度が最も低く、延性が最も高いもの. 良好な成形性と溶接性が要求される用途によく使用されます。, 板金成形や溶接など.

T4: これは溶体化熱処理焼戻しです, T6 および T651 焼き戻しよりも強度と硬度が低い. 良好な成形性が要求される用途によく使用されます。, チューブや構造部品など. T6: これは、熱処理および人工時効焼戻しを施した溶液です。, すべての焼き戻しの中で最高の強度と硬度を備えています。. 高い強度と剛性が必要な用途によく使用されます。, 航空機や航空宇宙部品など, 構造コンポーネント, および自動車部品. T651: これは、溶体化熱処理および応力除去焼戻しです。, T6 焼き戻しと同様の強度と硬度を提供します。, 応力腐食割れに対する耐性が向上しています. 高い強度と耐食性が必要な用途によく使用されます。, 海洋および海洋構造物など, および輸送コンポーネント. |

3003 h14 アルミニウム コイルは、h14 焼き戻しを指します。 3003 アルミニウムコイル。そしてH14焼き戻しは通常、取得することを意味します 1/2 硬さによる強さ.

5000 シリーズアルミニウム合金は、高強度で耐食性に優れたAl-Mg合金シリーズです。. 船舶の製造によく使用されます, オイルタンク, 船, 自動車, 建材・その他の分野.

アルミニウム合金 8011 アルミ箔は、アルミプラスチック複合板のベーステープや食品包装に広く使用されています。. プロのアルミホイルとして 8011 中国のメーカー, ファーウェイのアルミニウムは、 8011 アルミ箔の生産拠点として、 20 長年にわたる豊富なアルミ箔生産経験と熟練した加工技術.

調理器具の底に使用されるアルミニウム製の円は通常、と呼ばれます。 "アルミディスク" または "アルミディスク。" これらはアルミニウムの円形部分で、さまざまな形状の調理器具の底面または裏側に使用される可能性があります。, 鍋も含む, 鍋, そして濾し器.

河南華為アルミニウム有限公司, 株式会社, 中国河南省最大のアルミニウムサプライヤーのひとつ,私たちは2001年に設立され、輸出入と高品質のアルミニウム製品の豊富な経験があります

月~土, 8午前 – 午後 5 時

日曜日: 閉まっている

© 著作権© 2023 河南華為アルミニウム有限公司, 株式会社

最新のコメント

拝啓, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% 最小) サイズ:450 X32 X6MM. あなたのもの 570 EN-AW 1050 あ, 数量=3400KG

こんにちは, 以下の商品を提供していただけませんか: コイル 0,6х1250 (1000)mm EN AW-3105 5tons

こんにちは, アルミ板を提供してもらえますか? 実際には必要です: 110mm×1700mm×1700mm 5083 H111 - 21 pcs Next year planed is 177 個

素晴らしい記事. 私は喜んでいました, この記事を見つけたこと. 多くの人がそう思っています, 彼らはこの件に関して信頼できる知識を持っていること, しかし、そうでないこともよくあります. したがって、私の嬉しい驚きは. 私が感銘を受けた. この場所を絶対にお勧めし、もっと頻繁に戻ってきます, 新しいものを見るために.

アルミニウムストリップの要件