소개 3104 알루미늄 호일

3104 알루미늄 호일은 알루미늄 산업의 특수 합금입니다., 독특한 힘의 조합으로 유명합니다., 성형성, 및 내식성. 이 기사에서는 화학 성분을 탐구합니다., 기계적 성질, 이점, 애플리케이션, 유사한 합금과의 비교.

3104 알루미늄 호일

화학 성분 3104 알루미늄 호일

화학 성분의 3104 aluminum foil is crucial for its performance:

| 요소 |

백분율 (%) |

| 알루미늄 (알) |

균형 |

| 망간 (미네소타) |

0.8-1.4 |

| 마그네슘 (마그네슘) |

0.8-1.3 |

| 구리 (구) |

≤ 0.25 |

| 규소 (시) |

≤ 0.6 |

| 철 (철) |

≤ 0.8 |

| 아연 (증권 시세 표시기) |

≤ 0.25 |

| 타이타늄 (의) |

≤ 0.10 |

| 기타 요소 |

≤ 0.15 각, ≤ 0.5 총 |

The presence of manganese and magnesium enhances the alloy’s strength and formability, while copper and other elements contribute to its corrosion resistance.

기계적 성질

3104 aluminum foil exhibits the following mechanical properties:

- 인장 강도: 270-310 MPa

- 항복 강도: ≥ 160 MPa

- 신장: ≥ 10%

- 경도 (브리넬): 70-85 증권 시세 표시기

These properties make 3104 aluminum foil suitable for applications requiring high strength and good formability.

장점 3104 알루미늄 호일

- 고강도: Compared to pure aluminum, 3104 합금 has significantly higher strength due to the presence of manganese and magnesium.

- Excellent Formability: Its ability to be shaped without cracking or fracturing makes it ideal for complex shapes.

- 내식성: The alloying elements provide good resistance to atmospheric corrosion and saltwater.

- 용접성: Can be welded using conventional methods like TIG, 나, 및 저항 용접.

- 경량: As with all aluminum alloys, it offers a high strength-to-weight ratio.

- 재활용 가능성: 알루미늄은 재활용성이 뛰어납니다., reducing environmental impact.

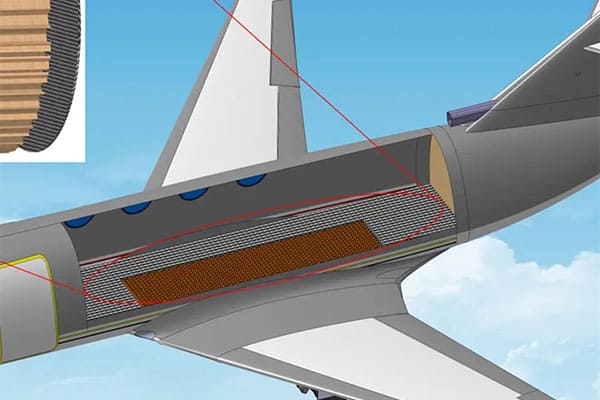

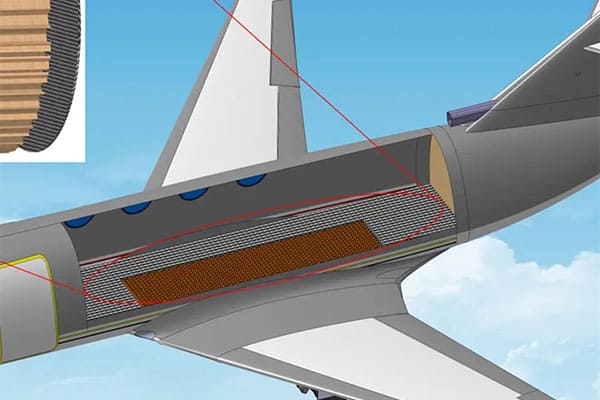

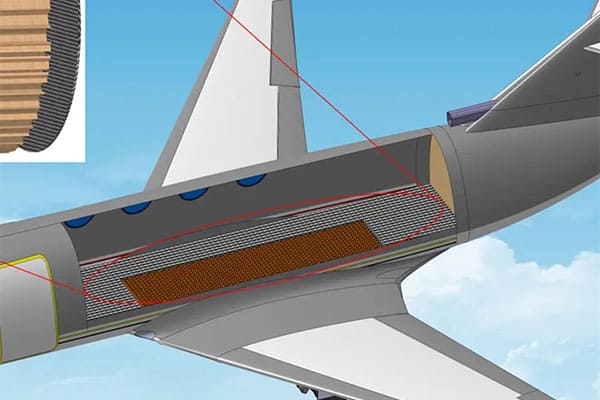

Honeycomb Core used 3104 알루미늄 호일

3104 알루미늄 합금, known for its high strength, 성형성, 및 내식성, finds extensive use in various industries. One of the most notable applications of 3104 aluminum foil is in the manufacturing of honeycomb panels, which are lightweight, 강한, and versatile structures.

3104 aluminum foil for honeycomb Panel

Honeycomb Panels: Structure and Composition

Honeycomb panels consist of:

- Face Sheets: Typically made from 3104 알루미늄 호일, providing strength and a smooth, corrosion-resistant surface.

- 핵심: A honeycomb structure, often made from aluminum, aramid, or other materials, which gives the panel its characteristic lightweight and high strength-to-weight ratio.

- Adhesive: Binds the face sheets to the core, ensuring structural integrity.

장점 3104 Aluminum Foil in Honeycomb Panels

- 고강도: The alloy’s high tensile strength (270-310 MPa) and yield strength (≥ 160 MPa) make it ideal for applications requiring structural integrity.

- 성형성: 3104 aluminum foil can be easily shaped into complex geometries without cracking or fracturing, facilitating the creation of curved or contoured honeycomb panels.

- 내식성: Its chemical composition provides good resistance to atmospheric and saltwater corrosion, making it suitable for outdoor and marine applications.

- 경량: Aluminum honeycomb panels are significantly lighter than solid panels, reducing weight in applications where this is critical.

- Thermal and Acoustic Insulation: The honeycomb structure provides excellent insulation properties, reducing heat transfer and sound transmission.

- 충격 저항: The combination of 3104 aluminum foil and honeycomb core offers excellent impact resistance, important in aerospace and automotive applications.

Applications of Honeycomb Panels Made with 3104 알루미늄 호일

항공우주 산업:

- 항공기 인테리어: Used for floor panels, ceiling panels, and sidewalls, providing a lightweight, 튼튼한, and fire-resistant solution.

- Aircraft Structures: Wing panels, 격벽, and control surfaces benefit from the strength and weight savings offered by honeycomb panels.

- Satellites and Spacecraft: Where weight reduction is critical, honeycomb panels are used for structural components, solar panels, and thermal insulation.

Honeycomb panels for aircraft

자동차 산업:

- Vehicle Interiors: Trunk floors, 좌석 구조, and interior panels to reduce weight while maintaining strength and safety.

- 본체 패널: Some high-end vehicles use honeycomb panels for their body panels, reducing weight and improving fuel efficiency.

건설:

- Building Facades: Used for curtain walls and cladding, providing both aesthetic appeal and structural integrity.

- 지붕 이기: Lightweight roofing materials, especially for curved or complex roof designs.

- Partitions and Ceilings: In commercial buildings, honeycomb panels are used for partition walls and suspended ceilings.

해양 응용 분야:

- Ship Interiors: Bulkheads, 파티션, and ceilings in ships, leveraging the alloy’s corrosion resistance.

- Decking: Lightweight decking materials, reducing the overall weight of the vessel.

운송:

- Railway Carriages: Interior panels, 바닥, and structural components in trains and subways.

- Bus and Truck Body: For body panels and interior components, reducing weight while maintaining durability.

전자공학:

- 방열판: The honeycomb structure provides excellent thermal dissipation, 그리고 3104 aluminum foil offers good thermal conductivity.

- 인클로저: Used for electronic equipment enclosures, providing both lightweight and robust protection.

기타 애플리케이션:

- 가구: 경량, strong furniture components, especially for outdoor and marine environments.

- 사이니지: Large, lightweight panels for outdoor advertising and signage.

- Art and Decor: Unique, lightweight structures for sculptures and decorative panels.

Manufacturing Process of Honeycomb Panels

- Face Sheet Preparation: 3104 aluminum foil is cut, 모양의, and sometimes pre-formed to fit the desired panel geometry.

- Core Fabrication: The honeycomb core is either expanded from a block or formed by bonding together corrugated sheets of aluminum.

- Adhesive Application: An adhesive is applied to the core or face sheets to ensure a strong bond.

- 라미네이션: The face sheets are laminated to the core under controlled conditions of temperature and pressure.

- 양생: The panel is cured to allow the adhesive to set, ensuring structural integrity.

- Finishing: Trimming, edge sealing, and sometimes painting or anodizing for additional protection and aesthetics.

포장됨 3104 알루미늄 호일

Comparison with Similar Alloys

Here is a comparison of 3104 aluminum foil with other commonly used aluminum alloys:

| 합금 |

인장 강도 (MPa) |

항복 강도 (MPa) |

신장 (%) |

내식성 |

응용 프로그램 |

| 3104 |

270-310 |

≥ 160 |

≥ 10 |

좋은 |

자동차, 포장, 건축 |

| 3003 |

140-180 |

≥ 110 |

≥ 18 |

Very Good |

General-purpose, 지붕 이기, 식품 용기 |

| 3105 |

185-215 |

≥ 145 |

≥ 10 |

좋은 |

건축자재, 식품 포장 |

| 5052 |

228-269 |

≥ 193 |

≥ 12 |

훌륭한 |

해병, 항공 우주, 수송 |

| 8011 |

125-165 |

≥ 110 |

≥ 2 |

좋은 |

식품 포장, industrial applications |

- 3104 대. 3003: 3104 offers higher strength but lower elongation compared to 3003, making it more suitable for structural applications where strength is a priority.

- 3104 대. 3105: Both have similar formability and strength, 하지만 3104 has a higher magnesium content, providing better strength.

- 3104 대. 5052: 5052 has superior corrosion resistance due to its higher magnesium content, 하지만 3104 is stronger.

- 3104 대. 8011: 8011 is commonly used for food packaging due to its excellent workability, 하지만 3104 offers better strength for more demanding applications.

결론

3104 aluminum foil stands out for its unique combination of high strength, 좋은 성형성, 및 내식성, making it an excellent choice for various industrial applications. Its chemical composition and mechanical properties make it particularly suitable for automotive, 항공 우주, 포장, 및 건설 산업. While it has similarities with other aluminum alloys, its specific properties offer advantages in specific applications where a balance of strength, 성형성, and corrosion resistance is required. As industries continue to seek lightweight, 튼튼한, and environmentally friendly materials, 3104 aluminum foil’s role is likely to expand, furthering its relevance in modern manufacturing and design.

최신 댓글

귀하에게, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% 최소) 크기:450 X32 X6 MM. 당신의 하나 570 EN-AW 1050 ㅏ, 수량=3400KG

안녕하세요, 다음과 같이 항목을 제공하는 것이 친절하겠습니까?: 코일 0,6х1250 (1000)mm EN AW-3105 5tons

안녕하세요, 알루미늄 판을 제공 할 수 있습니까?? 사실 나는 필요하다.: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 PCS (개)

훌륭한 기사. 나는 기뻤다, 나는이 기사를 발견. 많은 사람들이, 그들이 그것에 대해 정확한 지식을 가지고 있다는 것, 하지만 종종 그렇지 않다. 따라서 나의 즐거운 놀라움. 나는 감동. 나는 확실히이 장소를 추천하고 더 자주 돌아올 것입니다, 새로운 것을 보기 위해.

알루미늄 스트립의 요구 사항