5052 aluminum alloy is a representative product of the 5000 serie aluminiumlegering. It has excellent performance and is also the most common among the 5000 serie aluminiumlegeringen.

5052 aluminum alloy is a representative product of the 5000 serie aluminiumlegering. It has excellent performance and is also the most common among the 5000 serie aluminiumlegeringen.

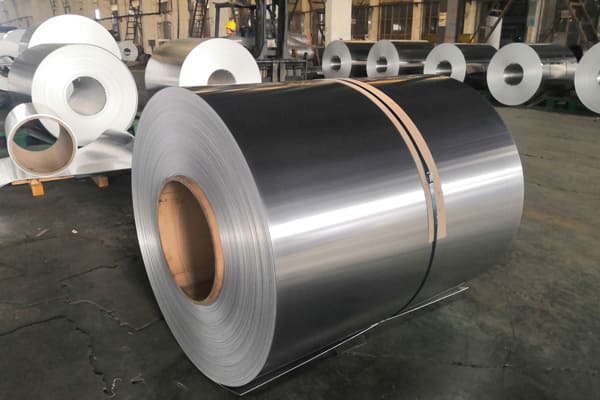

5052 aluminium spoel

5000 series aluminum alloy is an aluminum alloy with magnesium as the main alloy element. It is a non-heat treatable strengthened aluminum alloy. This series of alloys has a low density and higher strength than 1000 serie en 3000 serie aluminiumlegeringen. It is a medium-to-high-strength aluminum alloy and has good formability, corrosieweerstand, weldability and fatigue resistance.

Onder hen, the representative and widely used 5052 aluminum alloy is mainly used to manufacture aircraft fuel tanks, olie leidingen, sheet metal parts of transportation vehicles and ships, instrumenten, straatlantaarnbeugels en klinknagels, hardwareproducten, rear projection TVs and other electrical appliance casings. This article mainly takes 5052 alloy as an example to conduct analysis and research on cold rolling, annealing and user usage.

The raw materials are 99.7% pure aluminum ingots, and corresponding alloy elements are added to make 5052 alloy large flat ingots, which are then trial-rolled by a 1450mm double-coiling hot rolling mill, and finally rolled into hot-rolled coils with a size of: 7. Omm×1120mm.

7.0mm×1120mm×Cmm 5052 alloy aluminum coil is rolled in multiple passes on the 1850 six-fold irreversible cold rolling mill at a processing rate of about 30%. The rolled product thickness is 1.42mm, and is further trimmed on the 1850 recoiler. , and finally achieve industrial annealing to remove surface residual oil and ensure the performance of the final product.

5052 aluminum alloy production process

5052 alloy has a high magnesium content, poor processing performance, hard material, and stronger work hardening than 1000 serie en 3000 serie aluminiumlegeringen. Tijdens het walsproces, edge cracks are easy to expand, which may cause severe strip breakage and interrupt the rolling process. . In order to achieve stable continuous rolling, the roughness Ra of the rolling mill work roll is selected from 0.7 to 0.8um, and the surface is inspected pass by pass to ensure that the surface is good and there are no rolling marks.

The trimming of the finished product is controlled according to the width of 1019mm without a sleeve. Due to the hard material, it is difficult to start rolling. The speed of the entire trimming process is controlled at 200m/min, and the tension is around 21000N. When the edge crusher crushes, some of the edges are broken. Adhesion phenomenon, the overall process is relatively stable, and the plate shape is good when observed at the online entrance.

When rerolling and trimming, in order to reduce the residual oil stains on the board surface when the two small rollers of the edge trimming machine are pressed down, which affects the annealing effect, when producing 5052 legering, it is necessary to remove the small rollers on both sides.

Hot rolling process

The finished product status requirement is H32. Momenteel, the tensile strength is 210~230Mpa and the elongation can reach 12~22%. To meet customer requirements, the industrial annealing metal temperature can be determined to be 290~300~C. Combined with the furnace loading volume and roll size, Considering the degreasing condition of the surface, further determine the annealing system.

De 5052 aluminium spoel are straightened and cut into specifications of 1.42x1018x590ram, and are packaged and delivered in stacks. The end user conducts inspection and acceptance. The acceptance items focus on the thickness of different areas of the plate, the flatness of the final plate shape, and the surface quality.

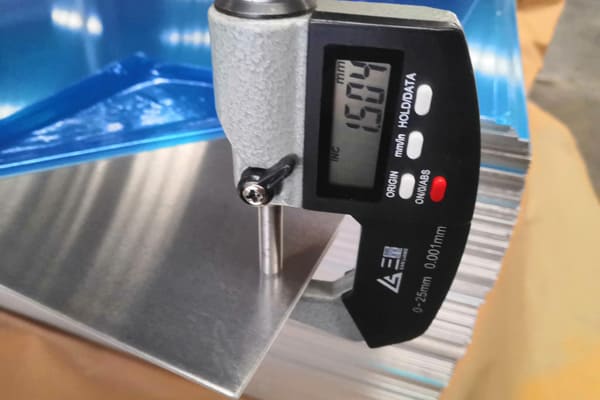

The user selects the head sample and measures the thickness around the plate to further detect the uniformity of the overall thickness.

5052 alloy aluminum sheet thickness detection

Flat shape detection is divided into flat shape detection after correction by the straightening machine and final stamping, riveting, and manual correction flat shape detection. Onder hen, the flat shape detection after correction is online detection, and the online detection platform at the beginning of stretch straightening, the operator performs slicing Measure to ensure final product quality.

After the 5052 alloy hot-rolled coil is cold-rolled to the finished product, the overall surface structure is uniform and delicate. The user does not conduct further inspections on the surface roughness. According to the current roughness control, it can meet the user’s requirements. There are no scratches on the upper and lower surfaces of each plate. Defects such as scratches and roll marks that affect use; annealing oil spots on the surface of the plate are the focus of inspection by the user. Once the straightened slice is found, the finished product cannot be sent to the user.

Huawei Aluminium is een toonaangevende fabrikant van aluminiumstrips in China, gespecialiseerd in de productie en verkoop van aluminium spoelen, aluminiumstrips en aluminiumfolies.

5086 aluminiumplaat is een hoge sterkte, corrosiebestendige al-mg-legering, veel gebruikt in de lucht- en ruimtevaart, vervoer, architecturale decoratie en andere gebieden.

3104 aluminiumfolie is een gespecialiseerde legering in de aluminiumindustrie, bekend om zijn unieke combinatie van kracht, vervormbaarheid, en corrosiebestendigheid. Dit artikel onderzoekt de chemische samenstelling, mechanische eigenschappen, voordelen, toepassingen, en vergelijkingen met soortgelijke legeringen.

Als u op zoek bent naar voorgelakte aluminium spoelen van topkwaliteit met verschillende legeringsmodellen en specificaties, Huawei Aluminium is uw ultieme keuze.

8021 aluminiumfolie heeft de kenmerken van reinheid en hygiëne, en kan met vele andere verpakkingsmaterialen tot een geïntegreerd verpakkingsmateriaal worden gemaakt. In aanvulling, het oppervlaktedrukeffect van 8021 aluminiumfolie is beter dan andere materialen. Daarom, 8021 aluminiumfolielegeringen kunnen ook worden gebruikt op het gebied van voedselverpakkingen.

3mm aluminiumplaat verwijst naar een aluminiumplaat met een dikte van 3 mm, en 3 mm is een gebruikelijke dikte van aluminiumplaat

Nr.52, Dongming-weg, Zhengzhou, Henan, China

Henan Huawei Aluminium Co., Ltd, Een van de grootste aluminiumleveranciers in China Henan,We zijn opgericht in 2001 en hebben een rijke ervaring in import en export en hoogwaardige aluminiumproducten

Ma – Za, 8AM – 17.00 uur

Zondag: Gesloten

© Auteursrecht © 2023 Henan Huawei Aluminium Co., Ltd

laatste Reacties

Geachte heer, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99,50% MIN) MAAT:450 X32 X6MM. JOUW EEN 570 NL-AW 1050 A, AANTAL=3400KG

Hallo, Zou u zo vriendelijk willen zijn om het item als volgt aan te bieden: Spoel 0,6х1250 (1000)mm EN AW-3105 5tons

Hallo, Kunt u mij aluminiumplaten aanbieden?? Eigenlijk heb ik het nodig: 110mm x 1700 mm x 1700 mm 5083 H111 - 21 pcs Next year planed is 177 stuks

Geweldig artikel. Ik was blij verrast, dat ik dit artikel heb gevonden. Veel mensen denken van wel, dat zij over betrouwbare kennis over dit onderwerp beschikken, maar dit is vaak niet het geval. Vandaar mijn aangename verrassing. ik ben onder de indruk. Ik zal deze plek zeker aanbevelen en vaker terugkomen, om nieuwe dingen te zien.

eis van aluminium strip