Materiaal van aluminiumlegering, als een metaalmateriaal gelegeerd met aluminium en andere elementen (zoals koper, magnesium, mangaan, silicium, zink, enz.), wordt gebruikt in de industriële productie en het dagelijks leven vanwege zijn unieke fysische en chemische eigenschappen en uitstekende prestaties.

Materiaal van aluminiumlegering, als een metaalmateriaal gelegeerd met aluminium en andere elementen (zoals koper, magnesium, mangaan, silicium, zink, enz.), wordt gebruikt in de industriële productie en het dagelijks leven vanwege zijn unieke fysische en chemische eigenschappen en uitstekende prestaties. speelt een belangrijke rol. Dit artikel introduceert de kenmerken van aluminiumlegeringen in detail en onderzoekt het brede scala aan toepassingen op verschillende gebieden.

Materialen van aluminiumlegering

Gangbare legeringen van aluminiumlegeringen bestrijken meerdere series. Hier zijn enkele belangrijke series aluminiumlegeringen en typische legeringen:

1000 serie aluminium: serie met een hoger zuiver aluminiumgehalte, zoals 1050, 1060, enz., voornamelijk gebruikt in gelegenheden waar hoge eisen worden gesteld aan geleidbaarheid en corrosiebestendigheid, zoals kabels, folies, en bekledingen voor chemische apparatuur.

2000 serie: Duraluminiumlegeringen met koper als belangrijkste legeringselement, zoals 2014 En 2024, hebben hoge sterkte-eigenschappen en worden veel gebruikt in de lucht- en ruimtevaart, structurele onderdelen voor spoorwegvervoer en productie van sportuitrusting.

3000 serie: Mangaan toegevoegd als het belangrijkste legeringselement, zoals 3003 En 3004, die goede roestwerende eigenschappen hebben en vaak in containers worden gebruikt, pijpen, auto-radiatoren, bouwmaterialen en andere gebieden.

3000 serie aluminiumlegering plaat

5000 serie: Bevat voornamelijk magnesium, zoals 5052, 5083, En 5754. Deze legeringen hebben een hoge corrosieweerstand en lasbaarheid, en worden meestal gebruikt in schepen, voertuigen, drukvaten, en het bouwen van vliesgevelsystemen.

6000 serie: Met magnesium en silicium als belangrijkste legeringselementen, zoals 6061, 6063, En 6082, het is een van de meest gebruikte series aluminiumlegeringen. Het heeft een matige sterkte en een uitstekende verwerkbaarheid. Het is geschikt voor diverse industriële profielen, pijpen, draden, en precisieonderdelen. Het wordt vaak gebruikt bij het bouwen van deur- en raamkozijnen, structurele componenten van vliegtuigen, fietsenrekken en andere producten.

7000 serie: Aluminiumlegeringen met hoge sterkte, zoals 7075, bevatten zink als het belangrijkste legeringselement. Ze hebben de hoogste sterkte maar relatief lage corrosieweerstand. Ze worden voornamelijk gebruikt in geavanceerde structurele componenten, raceonderdelen en hoogwaardige sportuitrusting in de luchtvaartindustrie.

Materialen van aluminiumlegeringen zijn alomtegenwoordig in het leven, en producten van aluminiumlegeringen bestaan in verschillende vormen. Hieronder volgt een introductie voor u.

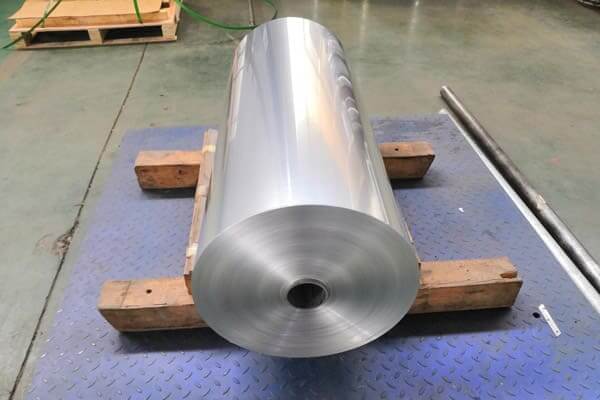

Materiaal aluminiumfolie

Huawei Aluminium is gespecialiseerd in de productie en verkoop van aluminium platen/rollen, aluminiumfolie, aluminiumwafels en andere materialen. Onze producten worden door klanten op maat gemaakt en de prijs is uitstekend. Als u enige behoeften heeft, Contacteer ons alsjeblieft.

1050 aluminium profiel: Dit is een soort industrieel puur aluminium met een hoge zuiverheid. Het aluminiumgehalte is meestal meer dan 99.5%, en het heeft een goede elektrische geleidbaarheid en corrosieweerstand. Het wordt voornamelijk gebruikt in productietoepassingen die geen hoge sterkte vereisen, maar wel een hoge elektrische of thermische geleidbaarheid, zoals afschermingslagen van stroomkabels, elektronische folies, en aluminiumfolie voor voedselverpakkingen. 1050 Aluminiumlegering kan worden verwerkt tot platen of folies van verschillende diktes en behoudt een goede vervormbaarheid na de O-toestand (Volledig gegloeid) behandeling.

3003 aluminium profiel: Deze serie aluminiumlegeringsmaterialen bevat een kleine hoeveelheid mangaan, waardoor het goede mechanische eigenschappen en corrosieweerstand heeft. Het is een veelgebruikte roestwerende aluminiumlegering. Het is geschikt voor het maken van tanks, auto radiatoren, huishoudelijk keukengerei en andere onderdelen die zowel lichtgewicht als corrosiebestendig zijn. 3003 aluminium plaat kan koud worden gewalst tot platen van verschillende diktes of worden geëxtrudeerd tot profielen met verschillende dwarsdoorsnedevormen. De statuscodes omvatten H14 (halfhard), H16 (gemiddelde hardheid), H18 (Volledig zacht), enz., en verschillende tempereertoestanden. Komt overeen met verschillende vorm- en gebruiksvereisten.

5052 aluminium profiel: Deze legering bevat magnesium en is een typische roestbestendige aluminiumlegering met hoge sterkte en uitstekende lasbaarheid. Het is geschikt voor gebruik in corrosiebestendige velden met hoge sterkte, zoals schepen, voertuigen, en containers, evenals complexe structurele onderdelen zoals drukvaten en ruimtevaartcomponenten. 5052 Materialen van aluminiumlegeringen worden vaak verwerkt tot dikke of middeldikke platen. De staten omvatten H32 (solide oplossing + lichte onvolledige gloeien), H34 (verder gloeien om de taaiheid te vergroten) en H38 (hogere mate van uitgloeien om de ductiliteit te verbeteren), afhankelijk van het eindproduct. Selecteer de overeenkomstige staat volgens de mechanische prestatie-eisen.

6061 aluminium profiel: Behoort tot de 6xxx-serie. Het voegt voornamelijk silicium en magnesium toe. Het kan worden versterkt na een warmtebehandeling, het heeft dus een hoge mechanische sterkte en een goede corrosieweerstand. Het wordt veel gebruikt in bouwconstructies, bruggen, fietsframes, ruimtevaartonderdelen en andere velden. 6061 aluminium profiel producten kunnen de status T6 hebben (solide oplossing + kunstmatige verouderingsbehandeling). In deze staat, het materiaal bereikt de beste balans tussen mechanische eigenschappen. De maatspecificaties kunnen worden aangepast aan de ontwerpvereisten, en kan worden geproduceerd van dunne platen tot dikwandige buizen.

7075 aluminium profiel: Deze ultrasterke aluminiumlegering bevat zink en magnesium en staat bekend als een “aerospace-grade” aluminiumlegering met extreem hoge sterkte en hardheid. Het wordt voornamelijk gebruikt in structurele onderdelen van vliegtuigen, hoogwaardige sportuitrusting, precisiemechanische onderdelen en andere toepassingsscenario's die een extreem hoge sterkte-gewichtsverhouding vereisen. 7075 Materialen van aluminiumlegeringen worden over het algemeen verwerkt onder T6- of T73/T76-omstandigheden om de beste mechanische eigenschappen te verkrijgen. De producten zijn er in verschillende vormen, dunne platen bedekken, dikke platen, balken, smeedstukken, enz.

5005 aluminiumplaat is een plaat van aluminiumlegering met gemiddelde sterkte, die middelmatige en hoge sterkte kan bereiken door koud werken, en het heeft een goede vervormbaarheid

5052 aluminiumplaat is onderdeel van de 5000 serie aluminium. De kwaliteiten in deze serie zijn gelegeerd met magnesium (2.5%) en hebben eigenschappen met gemiddelde tot hoge sterkte.

1050 Aluminiumrol behoort tot het commercieel zuivere smeedwerk 1000 reeks legeringen met een zuiverheid van 99.5% aluminium. Deze legering wordt meestal gebruikt voor koudwalsen of extrusie. Het heeft de kenmerken van hoge plasticiteit, corrosieweerstand, elektrische geleiding, en thermische geleidbaarheid.

Aluminium platen met traanplaat 4x8 zijn verkrijgbaar in de maten 6061-T6 en 3003-H14. ze hebben een hogere sterkte, slijtvastheid, dragend, bewerkbaarheid, corrosieweerstand, enz. Daarom, populair in de bouw, productie, voertuigen, schepen en diverse velden.

3105 Aluminium Sheet voegt nog enkele andere elementen toe op basis van puur aluminium, zoals cu, mg, En, mn, enz., het doel is om de sterkte van aluminiumlegeringen te verbeteren

Export van grondstoffen voor gecoate aluminiumfolie, fabriekslevering met de beste prijs, hoge kwaliteit, corrosiebestendigheid en lange levensduur

Nr.52, Dongming-weg, Zhengzhou, Henan, China

Henan Huawei Aluminium Co., Ltd, Een van de grootste aluminiumleveranciers in China Henan,We zijn opgericht in 2001 en hebben een rijke ervaring in import en export en hoogwaardige aluminiumproducten

Ma – Za, 8AM – 17.00 uur

Zondag: Gesloten

© Auteursrecht © 2023 Henan Huawei Aluminium Co., Ltd

laatste Reacties

Geachte heer, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99,50% MIN) MAAT:450 X32 X6MM. JOUW EEN 570 NL-AW 1050 A, AANTAL=3400KG

Hallo, Zou u zo vriendelijk willen zijn om het item als volgt aan te bieden: Spoel 0,6х1250 (1000)mm EN AW-3105 5tons

Hallo, Kunt u mij aluminiumplaten aanbieden?? Eigenlijk heb ik het nodig: 110mm x 1700 mm x 1700 mm 5083 H111 - 21 pcs Next year planed is 177 stuks

Geweldig artikel. Ik was blij verrast, dat ik dit artikel heb gevonden. Veel mensen denken van wel, dat zij over betrouwbare kennis over dit onderwerp beschikken, maar dit is vaak niet het geval. Vandaar mijn aangename verrassing. ik ben onder de indruk. Ik zal deze plek zeker aanbevelen en vaker terugkomen, om nieuwe dingen te zien.

eis van aluminium strip