De 6063 aluminiumplaat is een aluminiumlegering uit de 6000-serie met magnesium en silicium als de belangrijkste legeringselementen. De kracht van de 6063 legering is lager dan die van de 6061 legering, en het heeft een goede extrudeerbaarheid, corrosieweerstand, en goede oppervlaktebehandelingsprestaties.

6063 aluminum sheet is an aluminum alloy with magnesium and silicon as alloying elements. 6063 aluminum sheet generally has good mechanical properties and can be heat treated and welded. The comprehensive performance requirements of aluminum alloy are far higher than the industry standard.

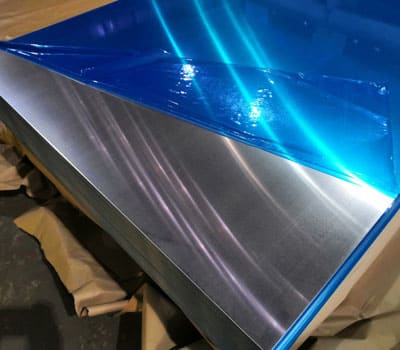

6063 aluminium plaat

De kracht van 6063 alloy is lower than that of 6061 aluminium, en het heeft een goede extrudeerbaarheid, corrosion resistance and good surface treatment performance. 6063 belongs to the low alloy Al-Mg-Si series high plasticity alloy. It has many valuable functions.

| Silicium | Ijzer | Koper | Magnesium | Mangaan | Chroom | Zink | Titanium | Anderen | Aluminium |

| 0.2~0,6 | 0.35 | 0.1 | 0.45~0.9 | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | Evenwicht |

De dichtheid van 6063 aluminum alloy is 2.69g/cm3.

6063 aluminiumplaat met blauwfilm

The above is about the element composition and element function of 6063 aluminium plaat. Shenzhen Wanxing Aluminum Co., Ltd. is a professional agent for sales of Southwest Aluminum, Korean Aluminum, and pure aluminum sheets and alloy sheets wholesaled by our major aluminum factories. With advanced Chinese and English technology and high-quality after-sales service, it is your best candidate.

Several key parameters in the melting and casting process: the furnace temperature is generally set at 1050°C during smelting, and the metal temperature is controlled not to exceed 770°C.

Melting and casting of 6063 aluminium

The melting and casting process of 6063 aluminium plaat is introduced above. After the material is melted at high temperature, it is directly cast into a product. It is generally dissolved in an electric arc furnace, then poured into high temperature resistant casting, and then cooled to crystallize, annealed or cut into products.

In production, mainly by controlling the melting atmosphere, melting temperature and cooling conditions to ensure high production efficiency, meet the requirements of crystal analysis, and form a network structure.

| Standards | ASTM B209 / ASME SB209 |

| Woedeaanval | O, T3,T4,T5, T6, T651 T6511 |

| Dikte | 0.3-600 mm |

| Breedte | 100-2600 mm |

| Lengte | 500-10000 mm |

| Oppervlak | Helder, gepolijst, hair line, brush, zandstraal, reliëf, etching, enz. |

| Finish | Mill, Customer specific finish |

| Aluminum Sheet/ Plate Coating | PVC Coated, Color Coated, Polyester, Fluorocarbon, polyurethane and epoxy coating |

| Type | Warm gewalst (HR) / Koudgewalst (CR) Laken |

| Dikte | Smeltpunt | Elasticiteitsmodulus | Elektrische weerstand | Warmtegeleiding | Thermische expansie |

| 2.69 g/cm3 | 600°C | 69.5 GPa | 0.035×10-6 O.m | 200 W/m.K | 23.5 X 10-6 /K |

| Mechanische eigenschappen | Metriek | Engels |

| Ultieme treksterkte | 241 MPa | 35000 psi |

| Treksterkte | 214 MPa | 31000 psi |

| Afschuifsterkte | 152 MPa | 22000 psi |

| Elasticiteitsmodulus | 68.9 GPa | 10000 ksi |

| Afschuifmodulus | 25.8 GPa | 3740 ksi |

1. The application of strips is widely used in decoration, verpakking, bouw, vervoer, elektronica, luchtvaart, ruimtevaart, weapons and other industries.

Building use 6063 aluminium plaat

2. Aluminum materials for aerospace are used to make aircraft skins, fuselage frames, girders, rotors, propellers, brandstoftanks, wall panels and landing gear pillars, as well as rocket forging rings, spacecraft wall panels, enz.

3. Aluminum materials for transportation are used for car body structural materials of automobiles, subway vehicles, railway passenger cars, high-speed passenger cars, deuren en ramen, shelves, automotive engine parts, airconditioners, radiatoren, body panels, wheels and ship materials.

4. Aluminum materials for packaging All-aluminum pop cans are mainly made of thin plates and foils as metal packaging materials to make cans, deksels, flessen, vaten, en verpakkingsfolies. Widely used in the packaging of beverages, voedsel, cosmetica, geneesmiddelen, industrial products, enz.

5. Aluminum materials for printing are mainly used to make PS plates. Aluminum-based PS plates are a new type of material for the printing industry and are used for automatic plate making and printing.

6. Aluminum materials for architectural decoration Aluminum alloys have good corrosion resistance, voldoende sterkte, excellent process performance and welding performance.

6063 aluminum sheet plate for car

7. Aluminum materials for electronic home appliances are mainly used in various busbars, wiring, geleiders, elektrische componenten, koelkasten, airconditioners, cables and other fields. Specificaties: Round rods and square rods represent applications including aerospace fixtures, electrical fixtures, and communication fields, and are also widely used in automated mechanical parts, precision machining, matrijzenbouw, electronics and precision instruments, SMT, PC board solder carriers, enz.

The 6063-t6 aluminum alloy means that its brand is 6063 legering, and the retreat process is T6 state. Over het algemeen, the yield strength value of T6 state treatment is: 210MPa, and the hardness of 6063-t6 is 73HB.

6063 is a representative product of the high-hardness aluminum plate alloy series, and its hardness can reach 95HB. Tegelijkertijd, 6063 aluminum alloy has the advantages of not easy to deform and high strength.

6063 aluminum sheet thickness measurement

The yield strength of 6063-T1 aluminum alloy aluminum plate is: 95Mpa and the hardness is: 42HB.

The yield strength of 6063-T5 aluminum alloy aluminum plate is: 175Mpa and the hardness is: 60HB.

The yield strength of the 6063-T6 aluminum alloy aluminum plate is: 210Mpa and the hardness is: 73HB.

The yield strength of the 6063-T832 aluminum alloy aluminum plate is: 240Mpa and the hardness is: 95HB.

Notes for reference: 10HW hardness corresponds to 120Mpa, 13HW hardness corresponds to 270MPa, you can extrapolate according to the state of the factory you want to know, and compare the reference data.

6063 aluminum sheet has half the strength of aluminum 6061 legeringen. It is typically produced with very smooth surfaces fit for anodizing and often used to make auto parts, architectural fabrication, window and door frames, aluminium furniture, electronic components as well as various consumer durable products.

| ALLOY | 6061 VS 6063 |

| Chemische samenstelling | In terms of Mg and SI, 6061 is 30-50% meer dan 6063. The most direct effect is that 6061 has a greater strengthening effect than 6063. |

| Mechanische eigenschappen | The strengthening effect of 6061 heat treatment is greater. In contrast, the higher the tensile strength, the greater the deformation resistance, so the plasticity of the 6061 alloy is lower than 6063. |

| Plasticiteit | 6061-T6 is used in occasions that require certain strength and hardness. 6063 is a representative alloy for extrusion with good extrudability. |

| Other Aspects | Oppervlakte behandeling: Beide 6061 En 6063 anodizing properties are very good. 6063 aluminum is better.

Bewerkbaarheid: Both are good. 6061 is better. Corrosieweerstand: Both are good. 6063 is slightly better. Lasbaarheid: 6063 is slightly better. Prijs: 6063 aluminum sheet price is a little higher than 6061. |

| Conclusie | Simply speaking, 6061’s advantage is strength, terwijl 6063 wins in extrudability. |

5086 aluminiumplaat is een hoge sterkte, corrosiebestendige al-mg-legering, veel gebruikt in de lucht- en ruimtevaart, vervoer, architecturale decoratie en andere gebieden.

6082 aluminiumplaat kan een warmtebehandeling ondergaan, versterkt en heeft een goede vervormbaarheid, lasbaarheid en bewerkbaarheid, ook bekend als structurele legering.

De 1000 serie aluminiumplaat is een serie pure aluminiumplaten. De samenstelling is voornamelijk aluminium, met een inhoud van meer dan 99%.

Aluminiumfoliecontainers van aluminiumfolie kunnen in verschillende vormen worden verwerkt, gebruikelijke legeringen zijn 8011, 3003, 3004, 5052 aluminiumfolie.

De verpakking van levensmiddelen, grondstof voor huishoudfolie 3004 aluminiumfolie, professionele productie-expert van aluminiumlegeringen, 20 productielijnen

Geperforeerde aluminiumplaten worden gemaakt van aluminiumplaten die zijn bewerkt met ronde gaten (of andere ontwerpen). De gaten kunnen in lijn of verspringend zijn om het aantal openingen te vergroten.

Nr.52, Dongming-weg, Zhengzhou, Henan, China

Henan Huawei Aluminium Co., Ltd, Een van de grootste aluminiumleveranciers in China Henan,We zijn opgericht in 2001 en hebben een rijke ervaring in import en export en hoogwaardige aluminiumproducten

Ma – Za, 8AM – 17.00 uur

Zondag: Gesloten

© Auteursrecht © 2023 Henan Huawei Aluminium Co., Ltd

laatste Reacties

Geachte heer, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99,50% MIN) MAAT:450 X32 X6MM. JOUW EEN 570 NL-AW 1050 A, AANTAL=3400KG

Hallo, Zou u zo vriendelijk willen zijn om het item als volgt aan te bieden: Spoel 0,6х1250 (1000)mm EN AW-3105 5tons

Hallo, Kunt u mij aluminiumplaten aanbieden?? Eigenlijk heb ik het nodig: 110mm x 1700 mm x 1700 mm 5083 H111 - 21 pcs Next year planed is 177 stuks

Geweldig artikel. Ik was blij verrast, dat ik dit artikel heb gevonden. Veel mensen denken van wel, dat zij over betrouwbare kennis over dit onderwerp beschikken, maar dit is vaak niet het geval. Vandaar mijn aangename verrassing. ik ben onder de indruk. Ik zal deze plek zeker aanbevelen en vaker terugkomen, om nieuwe dingen te zien.

eis van aluminium strip