5005 aluminiumplaat is een plaat van aluminiumlegering met gemiddelde sterkte, die middelmatige en hoge sterkte kan bereiken door koud werken, en het heeft een goede vervormbaarheid

5005 aluminium blad hoort bij 5 serie al-mg legering, Maar de belangrijkste legering MG -inhoud is lager dan andere 5 serie legeringen, bevattend 0.8% magnesium, Dus de corrosieweerstand is iets hoger dan 3 serie legeringen;

5005 Aluminiumlegering is een aluminiumlegering die resistent is tegen atmosferische corrosie. Het wordt gebruikt in decoratieve en architecturale toepassingen;

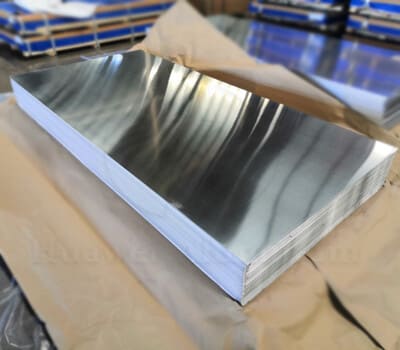

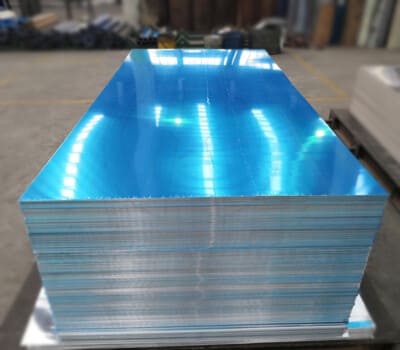

5005 Display van aluminium platen

5005 Aluminium plaat is een aluminium legeringsplaat met gemiddeld sterkte dat koud kan worden bewerkt om middelhoge sterkte te bereiken. Het heeft een goede vormbaarheid en is geschikt voor toepassingen die moeten worden gebogen, draaien, tekening, stempelen, en roll -vorming. Het wordt meestal gebruikt in toepassingen die moeten worden geanodiseerd.

| Al | mgr | Fe | En | Zn | Cu | Mn | Cr |

| 97-99.5% | 0.50 – 1.10% | 0 – 0.70% | 0 – 0.30% | 0 – 0.25% | 0 – 0.20% | 0 – 0.20% | 0 – 0.10% |

Chemische samenstelling voldoet aan het Chinees, Amerikaans, en Europese standaardspecificatie

Tabelbron: Wikipedia

Vergeleken met andere aluminiumlegeringsreeksen, Het heeft een hogere lassterkte, Werkbaarheid en corrosieweerstand.

Het heeft ook de lage dichtheid en uitstekende thermische geleidbaarheid die gemeenschappelijk is voor aluminiumlegeringen. Het is het meest gebruikte vel en plaatvorm van aluminium.

5005 Aluminium blad voor het bouwen van decoratie

De uitvoering van 5005 Aluminiumlegering is vergelijkbaar met die van 3 serie 3003 aluminium profiel, met gematigde kracht, Goede fusie, Werkbaarheid en vormbaarheid, maar het anodische oxidatie -effect is beter dan 3003 aluminium profiel, en de oxidefilm is helderder, en kan hetzelfde niveau bereiken als 6063 legering. kleur! Daarom, 5005 Aluminium plaat wordt vaak gebruikt in high-end brede breedte vliesgevel wandpanelen, architecturale decoraties, Automotive interieur materialen, instrumentenpanelen, geoxideerde materialen, kookgerei, geleiders, enz.

Merk op dat hoewel legering 5005 is geschikt om te anodiseren, strepen kunnen optreden.

| Eigendom | Bij | Waarde | eenheid |

| Dikte | 20°C | 2,700 | kg/m³ |

| Smeltbereik | 632 – 655 | °C | |

| Elasticiteitsmodulus | |||

| Spanning | 20°C | 68.2 | GPa |

| Torsie | 20°C | 25.9 | GPa |

| Compressie | 20°C | 69.5 | GPa |

| Specifieke hitte | 20°C | 900 | J/kg. °C |

| Gemiddelde expansiecoëfficiënt | 20°C | 23.75 | X 10 -6 / °C |

| Warmtegeleiding | 25°C | 201 | W / M. °C |

| Elektrische weerstand | 20°C | 0.034 | micro-ohm . M |

| Elektrische geleiding | |||

| Gelijk volume | 20°C | 52 | % IACS |

| Gelijk gewicht | 20°C | 172 | % IACS |

| Woedeaanval | 0.2% Bewijs stress, MPa min † | Treksterkte, MPa | Verlenging % min ‡ |

| O (gegloeid) | 35 | 105 – 145 | 12 – 22 |

| H12 | 95 | 125 – 165 | 2 – 8 |

| H14 | 115 | 145 – 185 | 1 – 6 |

| H16 | 135 | 165 – 205 | 1 – 3 |

| H18 | – | > 185 | 1 – 3 |

| H32 | 85 | 115 – 160 | 3 – 9 |

| H34 | 105 | 135 – 180 | 2 – 7 |

| H36 | 125 | 160 – 200 | 1 – 4 |

| H38 | – | > 180 | 1 – 4 |

H34 - gestabiliseerd - een thermische behandeling of warmte op lage temperatuur die tijdens de productie wordt geïntroduceerd die de mechanische eigenschappen stabiliseert en resterende interne spanning verlicht, Plus verbetert meestal de ductiliteit.

Tempers H116 en H321 kunnen worden gebruikt in vers en zout water.

5005 Aluminium plaat heeft dezelfde hoge corrosieweerstand als andere niet-verwarmde behandelbare aluminiumlegeringen. Het heeft ook een hoge weerstand tegen zwakke alkalische aandoeningen die gemeenschappelijk zijn voor 5000 serie legeringen.

De atmosferische corrosieweerstand van 5005 is vergelijkbaar met die van 3003.

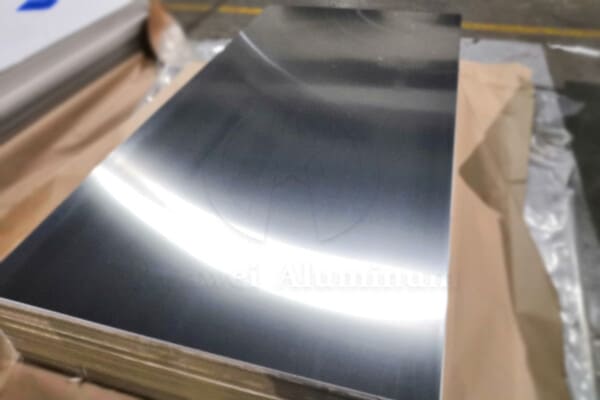

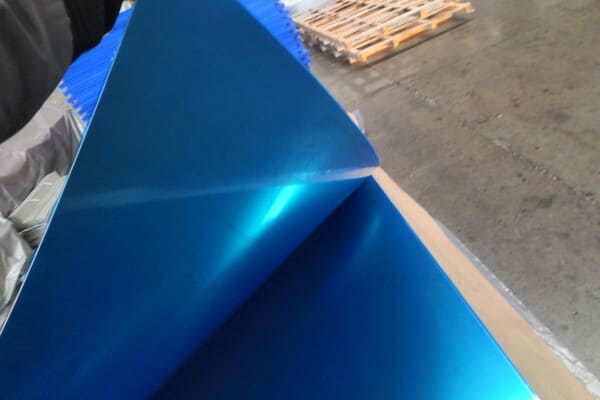

5005 Aluminium blad bedekt met blauwe film

Wanneer anodiseren wordt gebruikt om de corrosieweerstand te verbeteren, de film op 5005 is duidelijker dan dat op 3003 Aluminium plaat, en de kleur matching met 6063 Architecturale profielen zijn beter.

De corrosieweerstand van aluminiumlegeringen hangt af van de beschermende oxidefilm op het oppervlak. Wanneer beschadigd, De snelle reactie van aluminium en zuurstof kan gemakkelijk worden gerepareerd.

Maar als de film niet kan worden gerepareerd, De hoge reactiviteit van basismetalen kan leiden tot snelle corrosie, Dus aluminiumlegeringen zijn niet geschikt voor gebruik met het verminderen van media.

5005 kan gemakkelijk worden afgehandeld door conventionele methoden. Het moet met hoge snelheid worden verwerkt en volledig gesmeerd om thermische vervorming van het werkstuk te voorkomen. Scherpe gereedschappen zijn essentieel.

Hoge snelheid staal of wolfraamcarbide kan worden gebruikt. De snit moet diep en continu zijn, en de snijsnelheid moet hoog zijn. Woodworking machines kunnen geschikt zijn voor banen op korte termijn.

Bewerking van 5005 Aluminium plaat

5005 kan gemakkelijk worden gesoldeerd door standaardtechnieken. Meestal wolfraam gasbooglassen (TIG) of gas afgeschermd lassen (MIJ) lassen. Aluminium moet erg droog en schoon zijn om lasverontreiniging en porositeit te voorkomen.

Gebruik vulmetaal 1100, 4043 of 4047. 4043 is het meest scheurbestendig. Gebruik 1188 vul metaal voor de beste kleur matching. Het afschermingsgas moet droog zijn en vrij van waterstof.

Aluminium 5005 wordt gegloeid bij 345 ° C, De tijd en koelsnelheid bij deze temperatuur zijn niet kritisch. Stressverlichting is zelden vereist, maar kan worden gedaan op ongeveer 220 ° C, Als er bezorgdheid is over krachtverlies, Er moet een stressverlichtingstest worden uitgevoerd.

5005 is de aluminiumvereniging (AA) aanduiding voor dit materiaal. In Europese normen, het zal worden gegeven als en AW-5005. ALMG1(B) is de en chemische aanduiding. N41 is de Britse standaard (BS) aanduiding. En A95005 is het UNS -nummer.

Het is sindsdien in gebruik 1935, maar heeft alleen zijn standaardaanduiding ontvangen in 1954.

5005 Productieproces van aluminiumplaten

Aluminium 5005 is over het algemeen niet hot werkzaam. Het is gemakkelijk koud gevormd in de gegloeide toestand omdat het een relatief zachte en ductiele legering is. Het vormen van belastingen en gereedschaps- en perslijtage zijn over het algemeen minder dan koolstofstaal. Voor ponsen en blanco, De punch to die -klaring zou ongeveer moeten zijn 6% van de dikte van elke zijde in H32- en H34 -omstandigheden. Er zijn scherp gereedschap vereist.

5005 Aluminiumlegering die algemeen verkrijgbaar is in plat opgerichte spoel,Henan Huawei biedt hoge kwaliteit 5005 Aluminium plaat, Welkom bij bestelling.

Typische toepassingen: Architecturale toepassingen, Algemene verwerking, Folies met hoge sterkte.

Legering 5005 wordt vaak gebruikt in:

5005 Aluminium blad voor tank

3A21 aluminiumplaat is een aluminiumlegering uit de Al-Mn-serie, die behoort tot de lasbare aluminiumlegering LF21 en bekend staat om zijn uitstekende antiroesteigenschappen.

5052 aluminiumplaat is onderdeel van de 5000 serie aluminium. De kwaliteiten in deze serie zijn gelegeerd met magnesium (2.5%) en hebben eigenschappen met gemiddelde tot hoge sterkte.

Ontdek LDPE-composiet aluminiumfolie, ontworpen voor superieure vochtbestendigheid, thermische isolatie, en veelzijdige toepassingen in verpakkingen, bouw, en meer.

In dit artikel, we zullen de eigenschappen verkennen, voordelen, toepassingen, tempereerprocessen, en factoren waarmee u rekening moet houden bij het kiezen 6061 T4 T6 T651 aluminiumplaat voor uw project.

Vind duurzame en betrouwbare 4x10 aluminium platen voor uw behoeften. Ontdek ons ruime assortiment en bestel vandaag nog.

5086 aluminiumplaat is een hoge sterkte, corrosiebestendige al-mg-legering, veel gebruikt in de lucht- en ruimtevaart, vervoer, architecturale decoratie en andere gebieden.

Nr.52, Dongming-weg, Zhengzhou, Henan, China

Henan Huawei Aluminium Co., Ltd, Een van de grootste aluminiumleveranciers in China Henan,We zijn opgericht in 2001 en hebben een rijke ervaring in import en export en hoogwaardige aluminiumproducten

Ma – Za, 8AM – 17.00 uur

Zondag: Gesloten

© Auteursrecht © 2023 Henan Huawei Aluminium Co., Ltd

laatste Reacties

2000x3000mm aluminum sheet Price and transport

Onze vereiste hoeveelheid: Aluminiumplaat op rol (620mm x 1,20 mm) Aantal: 200 MT. Kunt u mij met spoed het nummer van de contactpersoon geven?. Thanks Matiur Rahman Director of Technical Sales dept.

Bonjour ; Wij zijn een straattheatergezelschap " carabose bedrijf " wij werken met de vlam . wij zijn op zoek naar aluminium reflectorplaat om een nieuw object te kunnen creëren op basis van een metaaldraad ontstoken met vloeibare ethanol van ongeveer hoogte 1 M . Welke producten heeft u ons te bieden? ? Cordialement Fabrice

Hallo, Ik ben geïnteresseerd in 3*1500*3500 mm 5754 H111 Checkered Aluminium Plate - Diamond Shape Powermaster Ltd. Moskou, Volokolamskoe-snelweg 1, str. 1, van. 19, Moskou, 125080

Goedemorgen, Me interesaría saber el costo de Paneles de nido de abeja de aluminio para usar como refuerzo interior de bandejas, boekenplanken , werkbladen die wij maken in AISI roestvrij staal 304. paneel dikte 10 j 20 mm, con la piel superior e inferior de aluminio espesor 0.8 mm glad of geborsteld of gewoon aluminium honingraatkern; met celgrootte 10 O 15 mm ( of standaard ) . grootte van de platen 1500 X 3000 mm of wat je ook aanbeveelt voor het gebruik dat ik het wil geven. Bij voorbaat hartelijk dank