Hydrofiele aluminiumfolie wordt verkregen door het oppervlak van aluminiumfolie te bekleden met een hydrofiele coating, het doel is om de hydrofiele eigenschappen te verbeteren (wateraantrekkend) prestaties van de aluminiumfolie, en het heeft een hogere warmteoverdrachtsefficiëntie en corrosieweerstand.

Hydrophilic Aluminum Foil is a specialized type of aluminum foil that has undergone a surface treatment to enhance its hydrophilic (wateraantrekkend) eigenschappen.

Hydrophilic Aluminum Foil is commonly used in various applications where efficient heat transfer and moisture management are required. The hydrophilic coating applied to the foil’s surface allows it to rapidly and uniformly distribute condensation or liquid, facilitating better heat exchange in heat exchangers, air conditioning systems, en radiatoren.

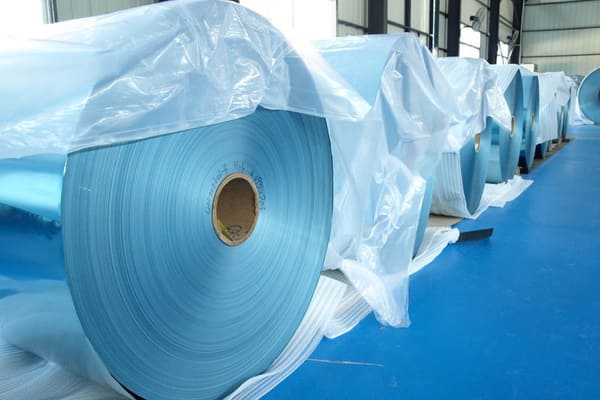

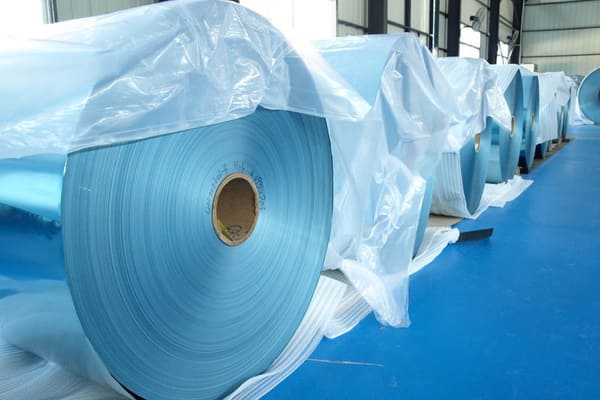

Hydrofiele aluminiumfolie

Compared to regular aluminum foil, which has hydrophobic properties and repels water, Hydrophilic Aluminum Foil offers superior performance in terms of heat transfer efficiency and corrosion resistance.

| Legering | Woedeaanval | Dikte(mm) | Treksterkte(MPA) | Elogation At 50mm Interval(%) | Cup I.E,mm |

| 1100 3102 8011 |

O | 0.08-0.20 | 80-110 | ≥20 | ≥6,0 |

| H22 | 0.08-0.20 | 100-130 | ≥18 | ≥6.5 | |

| H24 | 0.08-0.20 | 115-145 | ≥16 | ≥6,0 | |

| H26 | 0.08-0.20 | 135-165 | ≥10 | ≥5,5 | |

| H18 | 0.08-0.20 | ≥160 | ≥6 | – |

Opmerking: As the raw material of hydrophilic foil, 8011 aluminiumfolie is the most common alloy

| INNER DIAMETER | 76/152MM. |

| Thickness And Thickness Tolerance : | |

| Dikte(mm) | Dikte tolerantie |

| 0.080 | ±0.005 |

| > 0.115-0.130 | ±0.008 |

| > 0.130-0.32 | ±0.010 |

| Width And Tolerance : | |

| Breedte(mm) | Breedtetolerantie |

| ≤500 | ±0.005 |

| > 0.115-0.130 | ±0.008 |

| > 0.130-0.32 | ±0.010 |

| REEL : | |

| Breedte(mm) | Breedtetolerantie |

| ≤1400 | +2.0,0 |

| Telescopic And Layer : | |

| Telescopicy: 5MM | Laag: 0.5mm |

Opmerking: Hydrophilic aluminum foil is available in jumbo rolls, there is a certain relationship between tolerance and size.

| Item | Inspection Methods | Technical Requirements | |

| Film (Double Surface) |

Weighing | Anti-Corrosion:1.6—2.0G/M2

Hydrophilic:0.4-0.7G/M2 |

|

| Hechting | Cup Test:5mm | No De-Laying | |

| Jis4001 Network Test(100/100) | No Peeling | ||

| T Test(180 Degree) | No De-Laying | ||

| Hydrophilic | Initial Phase | Coating Status | ®≤5C |

| Continuous Test Phase | Dipping 100 Hours In Flow Water (300 L/H),Drying For 2 H, Then Test | Humidity100%:®≤20C | |

| Dry Cycle 300 Times | Humidity 100%:®≤28c | ||

| Dipping Into Volatilizing Solvant For 5min. And Drying It In Temperature 150 Degree, Then Dipping Into Flow Water For 5min. Then Drying In Oven Of Temperature 150 Degree For 150 Degree, Then Test It | Humidity 100%:®≤28C | ||

| Anti-Corrosion | Jisz2371 Nutual Salt Spray Test(72 H) | R.NO.≥9.8 | |

| Anti-Alikalinity | Sample Dip For 3min In 20% Naoh For 20 C+/-1 C | No Changing | |

| Anti-Hot | In 200+/-5c Oven For 10min. View Film Color | No Changing | |

| In 300+/-5 Oven For 5min, View The Color | Slightly Green | ||

| Anti-Oil | Dipping Into Volatilizing

Oil(Af-2c,Af-2as,T7k18b,Rf-190) Voor 24 H |

No Peeling | |

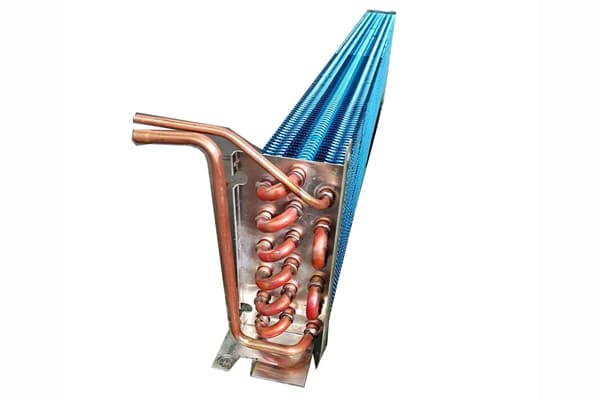

The hydrophilic coating on the aluminum foil promotes improved moisture absorption and increases the surface area, resulting in enhanced heat transfer efficiency. This allows for better cooling and heat dissipation, making it ideal for heat exchangers, air conditioning systems, and refrigeration units.

Hydrophilic Aluminum Foil is highly resistant to corrosion, making it suitable for applications in humid and corrosive environments. This resistance ensures the durability and longevity of the foil, even in challenging conditions, thereby reducing maintenance needs and extending the lifespan of equipment.

By facilitating efficient heat exchange, Hydrophilic Aluminum Foil helps optimize energy usage. It allows systems to cool more effectively, reducing the energy consumption required for maintaining desired temperatures. This can lead to energy savings and cost reduction in long-term operations.

Aluminium is een recyclebaar materiaal, and the hydrophilic foil can be recycled after use, contributing to sustainable practices and reducing environmental impact. Choosing Hydrophilic Aluminum Foil aligns with eco-friendly initiatives and supports a circular economy.

The production process of hydrophilic aluminum foil is basically the same as that of aluminum foil, except that 3 processes are added in the middle;

Aluminum Hydrophilic Foil Production Line

After the rolling of the aluminiumfolie is completed, the following 3 steps are performed:

Rewind after the above 3 stappen (this process is exactly the same as aluminum foil production)

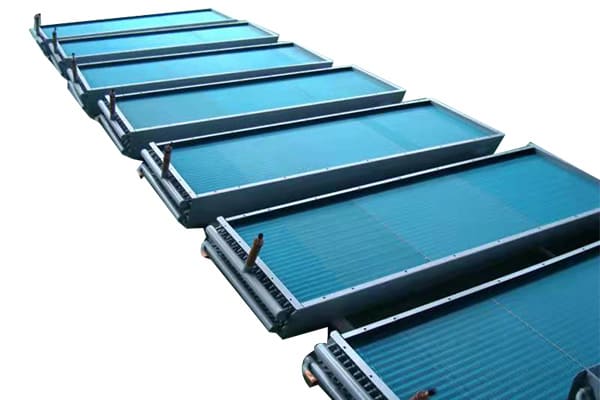

Hydrophilic foil is widely used in refrigeration equipment such as air conditioners and refrigerators, as well as some industrial heat exchange systems;

|

|

|

| Air conditioning systems | Refrigerator | Warmtewisselaars |

|

|

|

| Radiatoren | Condenser | Evaporator |

Dry Environment: Store hydrophilic aluminum foil in a dry environment with low humidity levels. Moisture can affect the hydrophilic properties of the foil and lead to degradation.

Temperature Control: Maintain a stable temperature for the storage area. Extreme temperatures can impact the structural integrity and performance of the foil.

Protection from Contaminants: Keep the hydrophilic foil away from dust, dirt, and other contaminants that could potentially affect its surface or hydrophilic coating.

Hydrophilic Aluminum Foil Storage

Avoid Pressure and Impact: Avoid placing heavy objects or applying pressure on the stored hydrophilic foil. Excessive pressure or impact can cause deformation or damage to the foil, compromising its effectiveness.

Ordinary aluminum foil cannot meet the requirements of energy saving, milieubescherming, corrosieweerstand, and antibacterial for air conditioners. Hydrophilic aluminum foil has strong hydrophilicity. The water droplets condensed on the heat sink are easy to spread and flow down the heat sink to avoid low ventilation effect.

The surface of the hydrophilic aluminum foil is covered with a hydrophilic layer, and the condensed water will spread rapidly on the hydrophilic aluminum foil without condensing into water droplets, which increases the heat transfer area, speeds up the cooling and heating speed, and effectively avoids the noise caused by air flow.

| Hydrofiele aluminiumfolie | Koperfolie | |

|---|---|---|

| Heat Transfer | Goed | Uitstekend |

| Moisture Management | Uitstekend | Beperkt |

| Corrosieweerstand | Goed | Uitstekend |

| Gewicht | Lichtgewicht | Relatively Heavy |

| Kosten | Betaalbaar | Duur |

| Beschikbaarheid | Widely Available | Beperkt |

| Elektrische geleiding | Gematigd | Uitstekend |

| Verenigbaarheid | Suitable for most applications | Suitable for specific applications |

Q:What is hydrophilic coating?

A:acrylic or epoxy

Q:Can Hydrophilic Aluminum Foil be recycled?

A:Ja, Hydrophilic Aluminum Foil can be recycled. Aluminum is highly recyclable and can be processed repeatedly without losing its properties. Recycling Hydrophilic Aluminum Foil helps conserve natural resources and reduces the environmental impact associated with primary aluminum production.

5754 aluminiumplaat heeft de kenmerken van uitstekende verwerkbaarheid, goede corrosiebestendigheid, lasbaarheid en gemakkelijk vormen. Als een smeedlegering, 5754 aluminiumplaat kan worden gevormd door walsen, extrusie, en smeden, maar niet door te gieten.

Ons 3003 Aluminiumfolieproducten zijn geëxporteerd naar Australië, Marokko, Syrië, Koeweit, Kalkoen, Saoedi-Arabië, VAE, Irak, Jordanië, Duitsland, Polen, Spanje, Brazilië, enz. Wij heten u oprecht welkom om onze fabriek te bezoeken.

Aluminiumfolie voor waterpijp wordt vaak gebruikt voor het bereiden en gebruiken van een waterpijp, ook wel shisha of waterpijp genoemd. Het dient een specifiek doel bij de bereiding van de waterpijp, met name bij de plaatsing en het beheer van de houtskool en tabak.

Huawei Aluminium aluminium schijven worden op grote schaal geëxporteerd naar Ghana, Guatemala, Burkina Faso, Algerije, Gaan, Kenia, Nigeria, Zuid-Afrika, Marokko en andere Afrikaanse landen; de Verenigde Arabische Emiraten, Jemen, Katar, Koeweit, Iran, Jordanië, Saoedi-Arabië en andere landen uit het Midden-Oosten.

6016 Aluminiumplaat maakt deel uit van de 6000-serie aluminiumlegeringen, die vooral bekend staan om hun uitstekende corrosieweerstand, goede lasbaarheid, en gemak van vormbaarheid.

6061 aluminiumplaat is een al-si-mg-legering die is versterkt door precipitatieharding. 6061 Aluminium heeft een hoge sterkte-gewichtsverhouding, bovengemiddelde corrosieweerstand, goede bewerkbaarheid, en is zeer geschikt voor lassen.

Nr.52, Dongming-weg, Zhengzhou, Henan, China

Henan Huawei Aluminium Co., Ltd, Een van de grootste aluminiumleveranciers in China Henan,We zijn opgericht in 2001 en hebben een rijke ervaring in import en export en hoogwaardige aluminiumproducten

Ma – Za, 8AM – 17.00 uur

Zondag: Gesloten

© Auteursrecht © 2023 Henan Huawei Aluminium Co., Ltd

laatste Reacties

Ik heb een offerte nodig 3000 serie aluminium vellen/spoelen (3104 H19) Voor tonijn kan de productie, Food-grade afwerking, Levering aan Mazzatlán, Mexico.

Ik ben van plan een zakenreis naar China en ik ben erg geïnteresseerd in je aluminium 8011 Producten voor voedselcontainerproductie. Ik zou graag je fabriek bezoeken tijdens mijn verblijf in China: Zie uw productielijnen (Folie rollen, gloeien, spleet, verpakking). Bespreek specificaties (8011-O humeur, dikte 0,05-0,08 mm, jumbo -rol). Bekijk uw kwaliteitscertificaten en exporteren ervaring. Kunt u het me alsjeblieft laten weten: Your available dates for a visit The location of your factory If you can provide an invitation letter for my business visa (M visum). Bedankt voor je vriendelijke ondersteuning. Ik kijk uit naar uw antwoord. Beste achting: LOUNIS MUSTAPHA company name:TOP BARQUETTE SELECT [email protected] what's up:213 770 91 69 43

Hallo ; Burak ünal i. Ik ben een functionaris van een bedrijf dat verpakking en schoonmaakproducten in Antalya levert. Ik doe ook P.E Stretch Transfer Job. Onze machines 9 vele 10 We zullen Micron Aluminium Foil -overdracht herzien. Wat ik van je wil, 9 of 10 micron 35 cm en 45 Cm jumbo fooys prijs voor fooy, Termin en ik wil de volgende informatie ; 35 Gemiddeld gewicht van CM Jumbo -folie. 45 Gemiddeld gewicht van CM Jumbo -folie. Dit komt omdat het een proef zal zijn 2 Hoeveel is onze minimale besteltonnage. Geniet van uw werk.

Wij zijn de onderdelen- en accessoires van een commerciële verlichting in Egypte hieronder zijn onze huidige vereisten voor productieproces van aluminium spoel (Legering 1050 humor o dikte 0.3 mm width 25cm=10tons width 29.5cm=6tons width 33.5cm=5tons width 37 cm=5tons kindly send us your best quotation ASAP according to our company below details: Hieronder staan onze bedrijfsgegevens : Volledige juridische bedrijfsnaam: Gerichte Ligth voor industriële investeringen ., Co address: Plot NR 8 - uitbreiding van 4e industrieel - Zone Sadat - Minofia - egypt Telephone number Ahmed nseem +201016644789 & +201010879400 A Moh El Shref : Menigte : +2 01016644789 Belasting -ID -nummer : 699-483-174

Ik schrijf om te informeren naar de producten die uw bedrijf aanbiedt. Ik ben vooral geïnteresseerd in het onderstaande product: *Aluminum Coil QTY-20 Units Could you please provide me with more information on these products, inclusief prijzen, beschikbaarheid, en eventuele aanvullende details die relevant kunnen zijn? en citeer ook uw gewone eenheidsprijs voor het leveren van dit product, Samen met uw kortingsprijs voor de volume -aankoop van volledige vrachtwagenbelasting. Opmerking: Bovendien voor het bovenstaande, Onze standaard betalingsvoorwaarden:Netto 15 dagen tot 30 Dagen vanaf de datum van levering met de factuur van de leverancier.