Gepoedercoate aluminiumplaat verwijst naar de aluminiumplaat die is verwerkt door middel van een poederspuitproces;

Powder coated aluminum sheet refers to the aluminum sheet processed by powder spraying process;

The purpose is to change the surface of the aluminum sheet, so that the surface has beautiful colors and patterns, and at the same time enhance the weather resistance of the aluminum sheet;

Gepoedercoat aluminium blad

Powder coating is to spray a powder coating on the surface of aluminum alloy substrate through electrostatic action. The adhesion, weather resistance, peeling resistance, strong UV resistance and dense coating of the coating are incomparable to the surface treatment of general aluminum profiles. The spraying effect is superior to the spraying process in terms of mechanical strength and aging resistance, and the cost is also lower. Under spray paint with the same effect.

PE: polyurethaan, polyurethane resin, epoxy resin, hydroxyl polyester resin and epoxy polyester resin

PVDF: Fluorkoolstofcoating

Bekledingsdikte: It can be divided into single coating (4μm-20 μm); dubbele coating (25μm-28 μm); 3 coating (35μm-38μm).

Momenteel, the current situation of Our country powder coated aluminium sheet is that the production capacity of ordinary products is excessive, and the production capacity of high-tech, high-precision and high-quality products is insufficient, which also leads to a large number of imports.

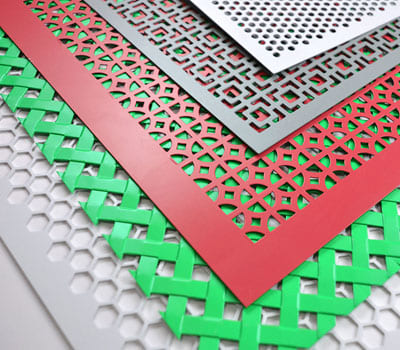

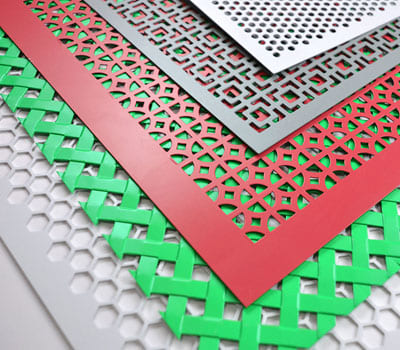

Punched Powder Coated Aluminum Sheet

Features of powder spraying: manual spraying equipment, automatic hanging type, simple construction, coating thickness of more than 30 micron, goede slagvastheid, abrasion resistance, corrosieweerstand, weather resistance, enz., the coating price is cheaper than fluorocarbon .

The biggest disadvantage of powder spraying is: fear of ultraviolet radiation from the sun, long-term exposure will cause natural fading, and the color difference between the sunny side and the non-sunny side of the door and window profiles will be obvious after a few years, usually within 2-5 jaren.

Loading → pretreatment (chromizing) → spraying → curing → dropping

Purpose of chromizing: to form a fine and stable chromizing film on the surface of aluminum. This film layer has a certain degree of wear resistance, corrosion resistance and good adsorption capacity, so that the paint can improve its adhesion when it is painted.

Powder Coating Process

Uitharding: Powder spraying is baked and leveled at high temperature and cured to form a final coating with different effects; in powder spraying, the baking and curing temperature and time of powder coating play a decisive role in the curing performance of the coating film. Daarom, it is necessary to classify the objects to be sprayed reasonably through multiple tests to determine the number and arrangement of the pendants, as well as the corresponding baking and curing temperature and time, in order to ensure the quality of the coated product.

| Huawei Coat’s Aluminum Powder coated sheet Data Sheet | |||

| Item | Standaard | Test Result | Opmerking |

| Bekledingsdikte | ≥40 um | ≥40 um | |

| Gloss | +/-5 | 30 | |

| Potloodhardheid | ≥HB | 2H | |

| Impact weerstand | 50KG.cm no peel off | 50KG.cm no peel off | |

| Wear Resistance | ≥5L/um | 16L/um | |

| Outlook | No flow marks, bubbels, inclusions, and other surface defects | No flow marks, bubbels, inclusions, and other surface defects | |

| Noise Insulation Factor | Noise insulation RW=40dB | ||

| Adhesive Force | Follow the standard | Kriging Grade 0 | |

| Chemische weerstand | Follow the standard | 15 minutes drip no bubbles, no change in appearance | Resistant to hydrochloric acid |

| E=0.48NBS | Resistance to nitric acid | ||

| No bubbles, no film loss | Detergent-resistant | ||

Powder coating of aluminum veneer is to use powder spraying equipment (electrostatic spraying machine) to spray powder coating on the surface of aluminum sheet, and there are many types of powder coating process. Under the action of static electricity, the powder will be evenly adsorbed on the surface of the workpiece to form a powder coating; the powder coating is then baked and leveled at a high temperature to become a final coating with different effects (different types of powder coating effects). The spraying effect of powder spraying is better than that of spraying paint in terms of mechanical strength, adhesion, corrosieweerstand, aging resistance, enz. Compared with spraying paint with the same effect, the cost is lower.

Gepoedercoat aluminium blad

Advantages of powder coating compared with traditional painting process:

Powder coating of aluminum sheets is a common surface coating technique that involves spraying fine powder paint onto the surface of aluminium platen through a spray gun, and then forming a solid coating during drying and curing. This technique has wide applications in many fields, here are some examples:

Construction and building materials: Powder coated aluminum sheets are commonly used in construction for the coating of exterior walls, raamkozijnen, deuren, railings and other metal components. This coating provides weather and corrosion resistance, making the building structure more durable.

Brown Powder Coated Aluminum Sheet

Household items: Household items such as furniture, lampen, door handles, enz. are also often used powder coating aluminum sheet technology to endow the products with rich colors and decorative effects.

Automobiles and vehicles: Powder coated aluminum sheets are used for surface coating of body, wielen, frame and other components in automobile manufacturing. This coating provides scratch resistance, corrosion resistance and improved appearance.

Elektronische producten: Powder coated aluminum sheets are also used on the casing and exterior parts of electronic products, such as computer casings, audio casings, enz., which can protect the equipment and give it a beautiful appearance.

Outdoor facilities: Seats and sunshade structures of outdoor facilities such as parks and squares can also use powder coated aluminum sheet technology to increase the durability and visual appeal of the product.

Industrial equipment: Mechanische uitrusting, pijpleidingen, storage tanks and other metal components in the industrial field can also be surface coated by powder spraying aluminum sheet technology to prolong service life and improve corrosion resistance.

Sports facilities: sports venues, fitness equipment, enz. can also use powder coated aluminum sheets for surface decoration and protection.

In het algemeen, powder coated aluminum sheets are widely used, mainly because they can provide metal surfaces with multiple functions such as durability, beauty, en corrosiebestendigheid, and are suitable for various industries and fields.

1/8 aluminiumplaat wordt vaak gebruikt bij de vervaardiging van tanks en schepen vanwege de sterke hardheid en corrosieweerstand, enz.

6082 aluminiumplaat kan een warmtebehandeling ondergaan, versterkt en heeft een goede vervormbaarheid, lasbaarheid en bewerkbaarheid, ook bekend als structurele legering.

De gebruikelijke legeringen van aluminiumfolie voor luchtkanalen zijn 1000 serie, 3000 serie en 8000 serie aluminiumfolie, die een sterke corrosieweerstand en vochtbestendigheid hebben.

1050 aluminium strips behoren tot de familie van commercieel zuivere smeedbare strips 1000 serie legeringen, en het aluminium is 99 zuiver. 5%, met uitstekende vormverwerkingseigenschappen, hoge corrosieweerstand, goede elektrische en thermische geleidbaarheid.

5052 aluminiumplaat is onderdeel van de 5000 serie aluminium. De kwaliteiten in deze serie zijn gelegeerd met magnesium (2.5%) en hebben eigenschappen met gemiddelde tot hoge sterkte.

1100 Aluminium Coil is de legering met de hoogste commerciële zuiverheid van alle aluminiumkwaliteiten, met een aluminiumgehalte (massafractie) van 99.00%. De sterkte ervan is relatief laag, en het heeft een uitstekende ductiliteit, vervormbaarheid, lasbaarheid, en corrosiebestendigheid.

Nr.52, Dongming-weg, Zhengzhou, Henan, China

Henan Huawei Aluminium Co., Ltd, Een van de grootste aluminiumleveranciers in China Henan,We zijn opgericht in 2001 en hebben een rijke ervaring in import en export en hoogwaardige aluminiumproducten

Ma – Za, 8AM – 17.00 uur

Zondag: Gesloten

© Auteursrecht © 2023 Henan Huawei Aluminium Co., Ltd

laatste Reacties

Geachte heer, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99,50% MIN) MAAT:450 X32 X6MM. JOUW EEN 570 NL-AW 1050 A, AANTAL=3400KG

Hallo, Zou u zo vriendelijk willen zijn om het item als volgt aan te bieden: Spoel 0,6х1250 (1000)mm EN AW-3105 5tons

Hallo, Kunt u mij aluminiumplaten aanbieden?? Eigenlijk heb ik het nodig: 110mm x 1700 mm x 1700 mm 5083 H111 - 21 pcs Next year planed is 177 stuks

Geweldig artikel. Ik was blij verrast, dat ik dit artikel heb gevonden. Veel mensen denken van wel, dat zij over betrouwbare kennis over dit onderwerp beschikken, maar dit is vaak niet het geval. Vandaar mijn aangename verrassing. ik ben onder de indruk. Ik zal deze plek zeker aanbevelen en vaker terugkomen, om nieuwe dingen te zien.

eis van aluminium strip