3104 aluminum foil is a specialized alloy in the aluminum industry, renowned for its unique combination of strength, şekillendirilebilirlik, ve korozyon direnci. This article explores the chemical composition, Mekanik özellikler, Avantaj -ları, uygulamalar, and comparisons with similar alloys.

3104 aluminum foil is a specialized alloy in the aluminum industry, renowned for its unique combination of strength, şekillendirilebilirlik, ve korozyon direnci. This article explores the chemical composition, Mekanik özellikler, Avantaj -ları, uygulamalar, and comparisons with similar alloys.

3104 aliminyum folyo

Kimyasal bileşimi 3104 aluminum foil is crucial for its performance:

| Öğe | Yüzde (%) |

| Alüminyum (Al) | Denge |

| Manganez (Mn) | 0.8-1.4 |

| Magnezyum (Mg) | 0.8-1.3 |

| Bakır (Cu) | ≤ 0.25 |

| Silikon (Si) | ≤ 0.6 |

| Ütü (Fe) | ≤ 0.8 |

| Çinko (çinko) | ≤ 0.25 |

| Titanyum (Nın-nin) | ≤ 0.10 |

| Diğer Unsurlar | ≤ 0.15 her biri, ≤ 0.5 toplam |

The presence of manganese and magnesium enhances the alloy’s strength and formability, while copper and other elements contribute to its corrosion resistance.

3104 aluminum foil exhibits the following mechanical properties:

These properties make 3104 aluminum foil suitable for applications requiring high strength and good formability.

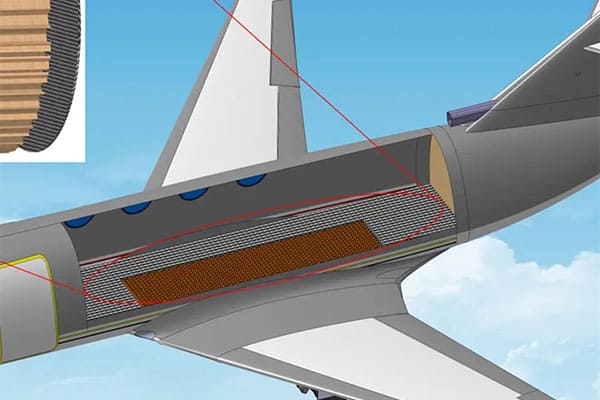

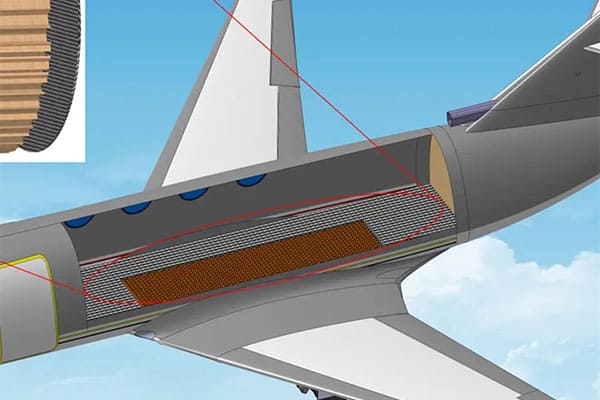

3104 alüminyum alaşım, known for its high strength, şekillendirilebilirlik, ve korozyon direnci, finds extensive use in various industries. One of the most notable applications of 3104 aluminum foil is in the manufacturing of honeycomb panels, which are lightweight, güçlü, and versatile structures.

3104 aluminum foil for honeycomb Panel

Honeycomb panels consist of:

Havacılık ve Uzay Endüstrisi:

Honeycomb panels for aircraft

Otomotiv Endüstrisi:

Yapı:

Denizcilik Uygulamaları:

Ulaştırma:

Elektronik:

Diğer uygulamalar:

Paketlenmiş 3104 aliminyum folyo

Here is a comparison of 3104 aluminum foil with other commonly used aluminum alloys:

| Alaşım | Gerilme direnci (Mpa) | Akma Dayanımı (Mpa) | Uzama (%) | Korozyon Direnci | Uygulamalar |

| 3104 | 270-310 | ≥ 160 | ≥ 10 | İyi | Otomotiv, Ambalaj, inşaat |

| 3003 | 140-180 | ≥ 110 | ≥ 18 | Very Good | General-purpose, çatı kaplama, yemek kapları |

| 3105 | 185-215 | ≥ 145 | ≥ 10 | İyi | Yapı malzemeleri, yemek paketleme |

| 5052 | 228-269 | ≥ 193 | ≥ 12 | Mükemmel | Deniz, Havacı -lık, ulaştırma |

| 8011 | 125-165 | ≥ 110 | ≥ 2 | İyi | Gıda ambalajı, industrial applications |

3104 aluminum foil stands out for its unique combination of high strength, iyi şekillendirilebilirlik, ve korozyon direnci, making it an excellent choice for various industrial applications. Its chemical composition and mechanical properties make it particularly suitable for automotive, Havacı -lık, Ambalaj, ve inşaat sektörleri. While it has similarities with other aluminum alloys, its specific properties offer advantages in specific applications where a balance of strength, şekillendirilebilirlik, and corrosion resistance is required. As industries continue to seek lightweight, dayanıklı, and environmentally friendly materials, 3104 aluminum foil’s role is likely to expand, furthering its relevance in modern manufacturing and design.

Uçak Sınıfı Alüminyum Levha Levha, yüksek sıcaklıkta oksidasyon gibi özel işlemlerden geçmiş bir alaşımdır., ve binlerce derece yüksek sıcaklığa veya güçlü darbeye dayanabilir.

1050 Alüminyum Bobin ticari olarak saf dövme aittir 1000 saflık derecesine sahip bir dizi alaşım 99.5% alüminyum. Bu alaşım genellikle soğuk haddeleme veya ekstrüzyon için kullanılır.. Yüksek plastisite özelliklerine sahiptir., korozyon direnci, elektiriksel iletkenlik, ve termal iletkenlik.

3104 aluminum foil is a specialized alloy in the aluminum industry, renowned for its unique combination of strength, şekillendirilebilirlik, ve korozyon direnci. This article explores the chemical composition, Mekanik özellikler, Avantaj -ları, uygulamalar, and comparisons with similar alloys.

Lambalar için ortak alüminyum disk çemberi 1050-O'dur, 1060-Ö, 1100-Ö, vb., çünkü abajur alüminyum disklerin damgalanmasıyla elde edilir, ve O-state alüminyum diskler daha iyi sünekliğe sahiptir ve damgalama işlemi için daha uygundur;

3003 alüminyum levha çok iyi korozyon direncine ve orta mukavemete sahip bir alaşımdır, Bu metalin yaygın olarak kullanılmasının nedeni, uygun fiyatlı ve güçlü olmasıdır..

3003 Giydirme cephe alüminyum levha bir binanın dış duvarıdır. Büyük yüksek binaların hafif bir duvarıdır ve belirli bir dekoratif etkiye sahiptir..

No.52, Dongming Yolu, Zhengzhou Belediyesi, Arjantin, Çin

Henan Huawei Alüminyum Co, Ltd Şti, Çin Henan'daki En Büyük Alüminyum Tedarikçilerinden Biri,Biz 2001 Yılında Kurulduk, Ve ithalat ve ihracat ve yüksek kaliteli alüminyum ürünler konusunda zengin deneyime sahibiz

Pzt – Ctst, 8– 5PM

Pazar: Kapalı

No.52, Dongming Yolu, Zhengzhou Belediyesi, Arjantin, Çin

© Telif hakkı © 2023 Henan Huawei Alüminyum Co, Ltd Şti

son Yorumlar

Sayın Bay, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) BOYUT:450 X32 X6 AA. SENİN BİRİN 570 TR-AW 1050 A, MİKTAR=3400KG

Merhaba, Aşağıdaki gibi öğe teklif etmek için çok nazik olur musunuz?: Bobin 0,6х1250 (1000)mm EN AW-3105 5tons

Merhaba, Bana Alüminyum plakalar sunabilir misiniz?? Aslında ihtiyacım var: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 Adet

Harika makale. çok sevindim, bu makaleyi buldum. Birçok insan görünüyor, hakkında kesin bilgiye sahip olduklarını, ama çoğu zaman değil. Bu yüzden benim hoş sürprizim. etkilendim. Burası kesinlikle tavsiye edeceğim ve daha sık geri geleceğim, yeni şeyler görmek için.

alüminyum şerit gereksinimi