軟包装アルミ箔は、食品包装や医薬品包装によく使われるアルミニウム製の薄い箔です。. 硬いアルミホイルと違って, 軟包装アルミ箔は柔らかく、さまざまな形状の容器に適応できます。, そのため、食品や医薬品の包装に広く使用されています。.

軟包装用アルミ箔は気密性、耐水性に優れているのが特徴です, 食品や医薬品を酸素の侵入や水分の揮発から保護します。, これにより、食品の鮮度や医薬品の保存期間が延長されます。. 加えて, 軟包装用アルミ箔は耐食性と遮光性も兼ね備えています, 食品や医薬品の光酸化による腐食を防ぎ、本来の品質を維持します。.

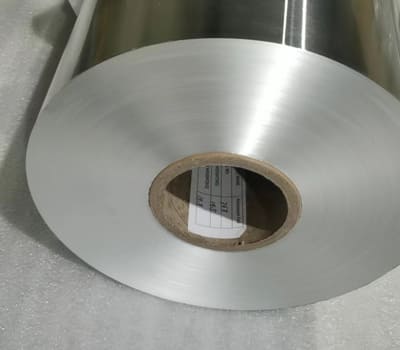

軟包装アルミ箔

軟包装アルミホイルのもう一つの利点は、持ち運びや開封が簡単であることです。, 消費者にとって使いやすいもの. 同時に, 軟包装用アルミ箔にも様々な柄や文字を印刷可能, 製品の美しさとブランド価値を高めることができます.

要するに, 軟包装アルミ箔は高品質の食品および医薬品の包装材料です。, 気密性の利点がある, 耐水性, 耐食性と遮光性, 製品の鮮度と品質を守ることができます, 同時に消費者の使用を促進し、製品の美学を増やす.

柔軟な包装用に選択されたアルミホイル合金グレードは、主に 1000 シリーズと 8000 シリーズ. 構成の観点から, 1000 シリーズには、他の合金コンポーネントが含まれています 8000 シリーズ. したがって, 柔軟なパッケージのためのアルミホイルの加工性に関して, のパフォーマンス 8000 シリーズアルミホイル 良くなります.

それは優れており、よりも優れた処理可能性を持っています 1000 シリーズ. その中で, 8011, 8021, そして 8079 アルミホイルはの重要な製品です 8000 シリーズアルミホイル. 彼らの優れたシーリングで, 可塑性, 耐食性, それらは食べ物で広く使用されています, 飲み物, そしてタバコ. 薬の包装で, 家庭用品およびその他の製品.

| 合金 | ALを除く主要な合金成分 | 代表的な用途 |

| 1145 | はい+信仰 0.55 ; 銅 0.05; ん 0.05 ; マグネシウム 0.05 ; 亜鉛 0.1 | ケーブルフォイル, 医薬品ホイル, 工業用ホイル |

| 1200 | はい+信仰 1.0 ; 銅 0.05; ん 0.05 ; 亜鉛 0.1 | ホースホイル |

| 1235 | はい+信仰 0.65 ; 銅 0.05; ん 0.05 ; マグネシウム 0.05 ; 亜鉛 0.1 | 医薬品複合箔 |

| 8011 | および0.5〜0.9 ; FE 0.6〜1.0 ; 銅 0.1 ; ん 0.2 ; マグネシウム 0.1 ; Cr 0.1 ; 亜鉛 0.1 | タバコ箔, 軟包装用ホイル, ヒートシールホイル, 薬ホイル, 工業用断熱材ホイル |

| 8021 | そして 0.15 ; Fe 1.2〜1.7 ; 銅 0.05 | ホースホイル, 薬ホイル, 薬用複合箔 |

| 8079 | および0.05〜0.3 ; FE 0.7〜1.3 ; 銅 0.05 ; 亜鉛 0.1 | ホースホイル, 医薬品ホイル, 薬用複合箔, 食品柔軟な包装箔 |

シーリング: 金属の結晶構造により高いバリア性を実現. 例えば, アルミニウム箔は厚さ6.3~9μmで、通常フィルムや紙などの材料と複合して強度とシール性を高めるために使用されます。.

遮光性: アルミホイルは可視光を遮断する固体金属です (紫外線も含めて).

安定性: 酸、アルカリを除く, ほとんどの物質に対して高い安定性を持っています.

非吸収性: 脂質を吸収しない, 油, 水やその他の液体.

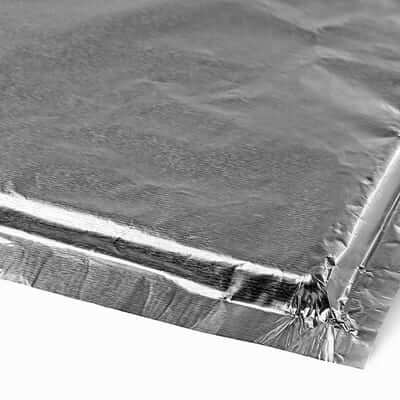

軟包装用ホイル

衛生と安全: アルミ箔の全製造工程が完了した後, 完成したアルミホイルは滅菌済みで、無菌状態で出荷できます。. アルミホイルは食品と接触しても安全で、細菌の増殖を引き起こしません。.

食品との接触: 欧州規格 EN602 アルミホイル包装は食品と接触する可能性があります, 西洋のアルミ箔は通常食品の包装に使用されます, 薬と化粧品.

味, 匂い: アルミホイルは無味です, 無臭の製品.

リサイクル可能: アルミニウムは品質を損なうことなくリサイクル可能. 最新の分離技術を使用する, アルミニウムは日用品から分別して活用できます.

完全に折りたたんだ状態: アルミニウムが完全に焼きなまされた後, 成形後は完全に柔らかい状態に戻り、良好な形状を維持できます。.

可塑性: アルミニウムは非常に優れた可塑性を備えており、バリア特性に影響を与えることなく大きな変形を起こすことができます。.

耐食性: 自然な状態で, アルミニウムは酸素の作用により酸化皮膜を形成します, それは良いシールドの役割を果たします. アルミニウムはpHの範囲でも安定です 4-9.

反射率: 輻射熱や光の反射率は 98%. アルミ箔の両面の反射率は同じです.

軟包装用アルミ箔の製造プロセスには通常、次の重要なリンクが含まれます。: ブランク素材の選択, アルミホイルを巻く, スリッティング, 洗浄と消毒, 等.

以下に、これらのリンクの具体的な手順と重要なポイントを詳しく紹介します。.

原材料 (ブランク) アルミニウム箔を製造するための製品は、主に鋳造圧延ブランクと熱間圧延ブランクに分けられます。. 熱間圧延ブランクとの比較, 鋳造圧延ブランクの品質を制御するのはさらに困難です. 鋳造圧延ビレットで圧延したアルミ箔は変形が非常に小さいため, 鋳造圧延ビレットの品質, 空気の通り道など, 内包物, 分離, 粗大粒子およびその他の欠陥, アルミ箔の圧延により直接的な影響を与える. 次の図はさまざまなブランクを示しています. 素材のクリスタルイメージレベル.

アルミ箔の主な圧延設備には以下のものがあります。: 粗圧延機, 中間圧延機, コイラー, および仕上げミル; アンコイラー, ハサミ, 焼鈍炉, 等. その後のプロセスで; 加圧ローラーの定期的な加工とメンテナンスのためのグラインダー. 各メーカーが生産する製品の品種や仕様に応じてカスタマイズされた装置もあります.

軟包装用アルミ箔の製造工程

アルミ箔カレンダー加工の製造工程:

アルミホイル粗目, 中圧延機と仕上げ圧延機は製品の厚さの範囲に応じて主に分類されます, 対応する制御モードが異なります.

粗圧延: 最小出口厚さ: 0.02~0.04mm, 主にロールギャップ位置制御とポストテンション制御に基づく;

中間圧延: 最小出口厚さ: 0.01んん, 張力制御を主眼とした;

仕上げ圧延: 最小出口厚さ: 0.004.4*2んん, 主に速度とポストテンションによって制御されます;

スリッティング: ニーズに応じて, 細かく巻いた二重アルミニウム箔をスリットして、さまざまな直径と幅の完成したアルミニウムコイルを形成します。, 一般的に内径は 3 インチと 6 インチに分けられます。;

焼入れ: 一般的に, 電気加熱式の正圧または負圧焼鈍炉が使用されます。, 必要に応じて異なるアニーリング温度と時間を設定して、アルミニウム箔を再結晶させ、油を除去して性能を回復するという目的を達成します。.

丸めたアルミホイルは通常より大きいです, 梱包や使用に適さないもの. したがって, 製造工程上スリット加工が必要となります. スリッティングは、専門的な機器を使用して、要件に応じて大きなアルミホイルをさまざまなサイズの小さな断片に切断することです。. スリット工程では、その後の生産工程をスムーズに進めるために、精度と効率に注意を払う必要があります。.

軟包装用アルミ箔は主に金属光沢を利用しています。, ライトバリア, 空気バリアとアルミ箔の確かな強度と延性. さまざまな用途に応じて, 強調されるパフォーマンスも異なります. 軟包装用アルミ箔は用途に応じて3つに分類されます。:

最初のカテゴリー, 食品および医薬品の包装, 主に密閉されています, 主にガスバリア性を重視, 光バリア特性, そして非毒性. この種のアルミホイルには、: 医薬品・医薬部外品の包装 (医療機器, 医薬品), 0.02んん, 0.015んん, 0.009んん, 0.007んん.

軟包装アルミ箔貼り付け

食べ物, 準食品 (歯磨き粉) 梱包, 0.015, 0.012, 0.009, 0.007んん.

2番目のカテゴリー, 装飾, 主に美学に重点を置く, 均一な表面光沢を強調. この種のアルミホイルには、: 各種印刷外箱, 広告.

3番目のカテゴリー, 最初のカテゴリと 2 番目のカテゴリの間, ある程度の密閉性とある程度の美観の両方が必要. 主にタバコ, アルコール, 食品包装.

|

|

|

| 薬のパッケージ | コーヒーの包装 | 食品の真空包装 |

|

|

|

| ティッシュの包装 | 食品包装 | ジャムの包装 |

軟包装用アルミ箔には現在解決すべき課題がいくつかある.

●軟包装用アルミ箔の表面状態の均一性が高すぎる. 良好な表面が必要な場合, 生産コストが大幅に増加する. これまでのところ, 良い解決策はありません.

●極厚品として, アルミホイルはその可塑性をほぼすべて使い果たします. 軟包装用アルミ箔のリワーク性は高くない, 新しい合金やプロセスを使用しているにもかかわらず, (例えば: 8011, 8079). 可塑性を大幅に改善する良い方法はまだありません. しかし, 軟包装複合製袋加工の方法では、この点はあまり考慮されていません。, 破裂が頻繁に起こるため.

● アルミ箔の可塑性を測定する指標は非科学的であり、アルミ箔の可塑性を真に表現することはできません。. 軟包装用アルミ箔の性能はまだ試行段階. 科学的指標測定なし, 製造検査ができない.

●科学的な厚さの選択, 合理的な複合技術, アルミ箔自体の性能と同じくらい重要なのが支持材です。. 合理的なマッチングにより製品品質の安定化だけでなくコスト削減にもつながります.

以上のメーカーとして 20 アルミ箔生産における長年の経験, Huawei Aluminium は、さまざまな合金の高品質アルミニウム箔を提供しています. 弊社でよく提供している軟包装用アルミ箔は以下の通りです。:

8011 ○軟包装用アルミ箔

合金: 1100 アルミホイル, 1235 アルミホイル, 8011 アルミホイル, 8021 アルミホイル, 8079 アルミホイル

厚さ: 0.005mm – 0.020mm

幅: 最大1850mm

ID: 3” (76んん) または6インチ (152んん)

一般的なアプリケーション: 真空包装袋, タバコの包装, テトラパックの包装, 食品包装袋, 断熱材, レトルト袋, 等.

8006 アルミニウム箔は、優れたバリア特性で知られる特殊な合金です。, 包装用途に最適です. 湿気から効果的に保護します, ライト, そして酸素, 食品の鮮度と品質の保持に貢献します.

6061 アルミニウムシートは、析出硬化によって強化されたal-si-mg合金です。. 6061 アルミニウムは高い強度対重量比を持っています, 平均以上の耐食性, 良好な機械加工性, 溶接に適しています.

中国のアルミホイルジャンボロールシールの専門メーカーおよび輸出業者として. 私たちはこの分野に何年も携わってきました 20 年, 私たちは工場と防塵ワークショップを持っています 100,000 平方メートル

河南華為アルミニウム有限公司, 株式会社, 中国河南省最大のアルミニウムサプライヤーのひとつ,私たちは2001年に設立され、輸出入と高品質のアルミニウム製品の豊富な経験があります

月~土, 8午前 – 午後 5 時

日曜日: 閉まっている

© 著作権© 2023 河南華為アルミニウム有限公司, 株式会社

最新のコメント

こんにちは, 興味があります 3*1500*3500 んん 5754 H111 Checkered Aluminium Plate - Diamond Shape Powermaster Ltd. モスクワ, ヴォロコラムスコエ高速道路 1, str. 1, の. 19, モスクワ, 125080

おはよう, Me interesaría saber el costo de Paneles de nido de abeja de aluminio para usar como refuerzo interior de bandejas, 本棚 , AISIステンレススチール製のカウンタートップ 304. パネルの厚さ 10 y 20 んん, con la piel superior e inferior de aluminio espesor 0.8 mm スムーズまたはブラッシュ仕上げ、または単なるアルミニウム ハニカム コア; セルサイズ付き 10 ああ 15 んん ( または標準 ) . プレートのサイズ 1500 バツ 3000 mmまたはあなたが使用するために推奨したものなら何でも差し上げたいです. よろしくお願いします

アルミ板の厚さのオファーを求めています 20 んん, ジャンルで 1060. 8000 kg

拝啓, アルミニウム 7075-T651 のプロバイダーを探しています。 1.0 または 1.5 厚さmm. 必要なのは約 180 のプレート 200 mm× 200 んん. こちらの見積もりと納期を教えていただけますか? よろしくお願いします. 敬具, フランシスコ・シルバ

こんにちは, このメッセージがあなたにうまく届くことを願っています. 貴社のウェブサイトを熟読しましたので、製品の詳細な価格見積もりが必要です; このメッセージにご返信いただきましたら、この注文/プロジェクトに関する詳細をお送りします。. あなたと取引できることを楽しみにしています. 温かい感謝を. よろしくお願いします, Ahmet Emir Purchase Manager SER MEKATRONIK SANAYI VE TICARET LTD.STI. トゥルクク O.S.B. マハレシ 216.ソカク NO:5/1 縮れた / テキルダーグ / Turkey Email: [email protected]