Aluminum alloys are widely used in a variety of industries due to their high strength-to-weight ratio, uitstekende corrosieweerstand, and good thermal and electrical conductivity. These alloys are composed of a combination of aluminum and other metals, such as copper, zink, magnesium, en silicium, to achieve specific properties and characteristics. In dit artikel, we will compare two popular aluminum alloys: 3003 aluminium En 6061 aluminium.

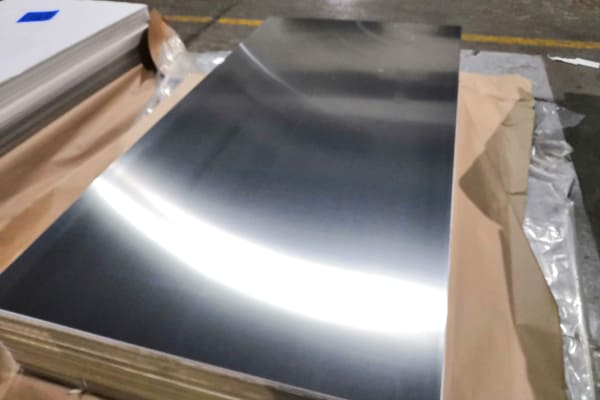

3003-h24-aluminum-sheet

3003 aluminum is a non-heat-treatable alloy that contains manganese as its primary alloying element. This alloy has excellent workability, high resistance to corrosion, and good weldability. 3003 aluminum is commonly used in the construction of heat exchangers, storage tanks, en drukvaten. It is also used for roofing and cladding in the building and construction industry.

Samenstelling en eigenschappen van 3003 Aluminium

3003 aluminum is composed of 97.5% aluminium, 0.1% koper, 1.2% mangaan, En 1.2% zink. This alloy has a density of 2.73 g/cm3, a melting point of 655°C, and a thermal conductivity of 204 W/m-K. 3003 aluminum has an ultimate tensile strength of 125-185 MPa and a yield strength of 55-110 MPa.

6061 aluminum is a heat-treatable alloy that contains magnesium and silicon as its primary alloying elements. This alloy has good machinability, uitstekende corrosieweerstand, en hoge sterkte. 6061 aluminium is commonly used in the manufacture of aircraft structures, auto-onderdelen, en fietsframes.

Samenstelling en eigenschappen van 6061 Aluminium

6061 aluminum is composed of 97.9% aluminium, 0.6% silicium, 1.0% magnesium, En 0.28% koper. Density of 6061 aluminium is 2.7 g/cm3, a melting point of 582-651°C, and a thermal conductivity of 151-202 W/m-K. 6061 aluminum has an ultimate tensile strength of 290-320 MPa and a yield strength of 240-260 MPa.

6061 aluminium

3003 aluminum has a lower density than 6061 aluminium, which makes it lighter and more suitable for applications that require a low weight-to-volume ratio. Echter, 6061 aluminum has a higher strength-to-weight ratio, which makes it more suitable for applications that require a high load-bearing capacity.

3003 aluminum has a lower ultimate tensile strength and yield strength than 6061 aluminium, which makes it less suitable for applications that require high strength and durability. Echter, 3003 aluminum has better formability and ductility than 6061 aluminium, which makes it more suitable for applications that require complex shapes and bending.

Beide 3003 aluminum and 6061 aluminum have excellent corrosion resistance, met 3003 aluminum being more resistant to corrosion than 6061 aluminum in certain environments. Echter, 6061 aluminum has better resistance to stress corrosion cracking and pitting corrosion than 3003 aluminium.

More detials abou 6061 aluminium legering

The advantages of 3003 aluminum include its excellent formability, high resistance to corrosion, and good weldability. Its disadvantages include its lower strength and load-bearing capacity compared to 6061 aluminium.

The advantages of 6061 aluminum include its high strength-to-weight ratio, uitstekende corrosieweerstand, and good machinability. Its disadvantages include its lower formability and ductility compared to 3003 aluminium.

3003 aluminum is commonly used in the construction of heat exchangers, storage tanks, and pressure vessels due to its high resistance to corrosion. It is also used for roofing and cladding in the building and construction industry, as well as for cooking utensils and food processing equipment due to its non-toxic and non-reactive properties.

6061 aluminum is commonly used in the manufacture of aircraft structures, auto-onderdelen, and bicycle frames due to its high strength-to-weight ratio. It is also used for marine and transportation applications, as well as for structural and architectural components in the building and construction industry.

When choosing between 3003 aluminum and 6061 aluminium, it is important to consider the specific requirements of your application. Factors to consider include the desired strength, gewicht, corrosieweerstand, vervormbaarheid, and cost of the alloy.

For applications that require a high load-bearing capacity, such as aircraft structures and automotive parts, 6061 aluminum is a better choice due to its high strength-to-weight ratio. For applications that require excellent formability and ductility, such as cooking utensils and food processing equipment, 3003 aluminum is a better choice.

The cost of each alloy will depend on factors such as the specific grade of the alloy, the quantity ordered, and the current market prices. In het algemeen, 3003 aluminum is less expensive than 6061 aluminum due to its lower alloying content.

Ten slotte, both 3003 aluminum and 6061 aluminum have their advantages and disadvantages, and the choice between the two will depend on the specific requirements of your application. By considering factors such as strength, gewicht, corrosieweerstand, vervormbaarheid, and cost, you can make an informed decision about which alloy is best suited for your needs.

5086 aluminiumplaat is een hoge sterkte, corrosiebestendige al-mg-legering, veel gebruikt in de lucht- en ruimtevaart, vervoer, architecturale decoratie en andere gebieden.

Aluminiumfolie voor waterpijp wordt vaak gebruikt voor het bereiden en gebruiken van een waterpijp, ook wel shisha of waterpijp genoemd. Het dient een specifiek doel bij de bereiding van de waterpijp, met name bij de plaatsing en het beheer van de houtskool en tabak.

1060 Aluminium spoel is samengesteld uit 99.6% aluminium, die vergelijkbaar is met de 1050 legering van dezelfde familie, maar het aluminiumgehalte verschilt per 0.1%.

4x8 aluminiumplaat is een gangbare maat aluminiumplaat, ook bekend als aluminiumplaat van standaardformaat, standaardblad genoemd.

3A21 aluminiumplaat is een aluminiumlegering uit de Al-Mn-serie, die behoort tot de lasbare aluminiumlegering LF21 en bekend staat om zijn uitstekende antiroesteigenschappen.

3004 Aluminiumplaat is een aluminiumlegering van gemiddelde sterkte met mangaan en magnesium als de belangrijkste legeringselementen. De kracht is groter dan 3003 Aluminium plaat, maar de ductiliteit is lager.

Nr.52, Dongming-weg, Zhengzhou, Henan, China

Henan Huawei Aluminium Co., Ltd, Een van de grootste aluminiumleveranciers in China Henan,We zijn opgericht in 2001 en hebben een rijke ervaring in import en export en hoogwaardige aluminiumproducten

Ma – Za, 8AM – 17.00 uur

Zondag: Gesloten

© Auteursrecht © 2023 Henan Huawei Aluminium Co., Ltd

laatste Reacties

Geachte heer, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99,50% MIN) MAAT:450 X32 X6MM. JOUW EEN 570 NL-AW 1050 A, AANTAL=3400KG

Hallo, Zou u zo vriendelijk willen zijn om het item als volgt aan te bieden: Spoel 0,6х1250 (1000)mm EN AW-3105 5tons

Hallo, Kunt u mij aluminiumplaten aanbieden?? Eigenlijk heb ik het nodig: 110mm x 1700 mm x 1700 mm 5083 H111 - 21 pcs Next year planed is 177 stuks

Geweldig artikel. Ik was blij verrast, dat ik dit artikel heb gevonden. Veel mensen denken van wel, dat zij over betrouwbare kennis over dit onderwerp beschikken, maar dit is vaak niet het geval. Vandaar mijn aangename verrassing. ik ben onder de indruk. Ik zal deze plek zeker aanbevelen en vaker terugkomen, om nieuwe dingen te zien.

eis van aluminium strip