Core Concept

8079 aluminum foil is a representative of the 8××× series aluminum alloys. Its main components are aluminum (Al≥98.3%), iron (Fe 1.0–1.5%), a kremík (Si≤0.05%).

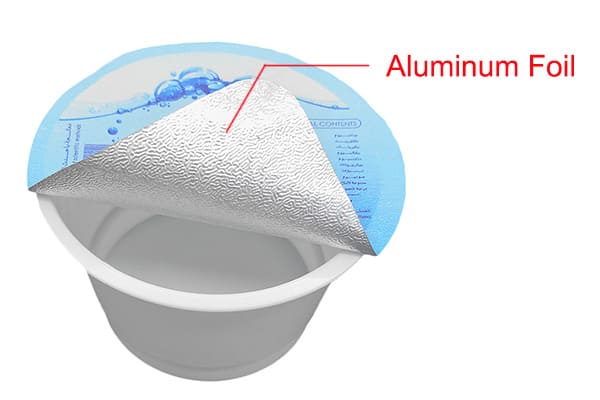

It is made through a cold rolling process and is designed for high sealing requirements such as food and medicine.

As the core material of “Lids”, 8079 aluminum foil is widely used in fresh milk covers, yogurt covers, and pharmaceutical capsule covers due to its excellent heat sealing performance and barrier properties.

Core features

High ductility: elongation ≥15%, suitable for deep-drawing complex cover structures.

Odpor: the surface oxide layer resists acid, alkali and salt spray environments, extending the life of the packaging.

Sealing performance: uniform thickness (usually 20-30 mikróny), strong heat-sealing bonding with plastic or paper substrates.

Huawei 8079 aluminum foil display

Industry Background

With the increasing requirements for safety and freshness of food and pharmaceutical packaging, 8079 aluminum foil has become the preferred material due to its unique properties.

The exceptional performance of 8079 aluminum foil in lid applications is directly attributable to its specific material properties, which are carefully controlled during the manufacturing process.

8079 aluminum alloy primarily consists of aluminum, with significant additions of iron (0.7-1.3%), kremík (0.4-0.9%), and manganese (0.15-0.40%).

Trace amounts of other elements are also present. This specific composition enhances strength, tepelný odpor, a formovateľnosť.

| Prvok | Percentuálny podiel (%) |

| Hliník (Al) | Vyvážiť |

| Žehlička (FE) | 0.7 - 1.3 |

| Kremík (A) | 0.4 - 0.9 |

| Mangán (Mn) | 0.15 - 0.40 |

| Meď (Cu) | ≤ 0.05 |

| Horčík (Mg) | ≤ 0.05 |

| Zinok (Zn) | ≤ 0.05 |

| Titán (Z) | ≤ 0.03 |

| Ďalší (každý) | ≤ 0.03 |

| Ďalší (súčet) | ≤ 0.10 |

Key mechanical properties crucial for lid performance include:

These properties are tailored through processing to suit specific lid requirements.

Žíhanie (heat treatment) softens the foil, making it more ductile and easier to form and seal. It also relieves internal stresses from rolling.

The degree of annealing determines the temper (tvrdosť), influencing suitability for different lid applications.

Surface characteristics are vital for sealing, tlač, and coating:

Controlled surface properties ensure reliable lid performance.

The production of high-quality 8079 hliníková fólia for lids involves a series of carefully controlled processes, from the initial casting of the aluminum alloy to the final slitting and packaging of the foil rolls.

The primary steps in the production of 8079 aluminum foil for lids are:

Aluminum Alloy Casting:

The process begins with melting high-purity aluminum and alloying it with the specified amounts of iron, kremík, manganese, and other elements according to the 8079 alloy standard.

The molten alloy is then cast into large ingots or slabs using continuous casting or other advanced casting techniques.

The homogeneity and quality of the cast ingot are crucial for the subsequent rolling processes and the final properties of the foil.

Rolling and Annealing:

The cast ingots are first subjected to hot rolling to reduce their thickness to a more manageable size.

These hot-rolled coils are then further reduced in thickness through multiple passes of cold rolling.

Cold rolling increases the strength and hardness of the aluminum, so intermediate annealing is performed at specific stages to restore ductility and relieve internal stresses.

The final rolling pass achieves the desired gauge (hrúbka) of the aluminum foil.

Precise control over rolling pressure, rýchlosť, and temperature is essential to ensure uniform thickness and the required mechanical properties.

Ošetrenie povrchom:

After rolling, the aluminum foil may undergo various surface treatments to prepare it for specific applications. These treatments can include:

Coating and Laminating (Voliteľný):

For many lid applications, the aluminum foil is coated with heat-sealable lacquers or laminated with polymer films.

These coatings and laminates provide the functionality required for sealing to different container materials and can also enhance barrier properties or provide printable surfaces.

The selection of coating or laminate depends on the specific application and the material of the container.

Slitting and Packaging:

The wide rolls of aluminum foil are then slit into narrower rolls of the required width, according to customer specifications.

Strict quality control checks are performed during slitting to ensure consistent width and to detect any defects.

Finally, the finished rolls of 8079 aluminum foil are carefully packaged to protect them from damage and contamination during storage and transportation.

Packaging typically involves wrapping with protective materials and securing the rolls to prevent movement.

8079 aluminum foil Slitting

Stringent quality control measures are implemented throughout the production process of 8079 aluminum foil to ensure that the final product meets the required specifications and performance standards for lid applications.

These measures include:

These rigorous quality control measures guarantee that 8079 aluminum foil for lids is a reliable and high-performing packaging material.

| Defect | Cause | Solution |

|---|---|---|

| Pinhole Formation | Impurities in base metal | Use high-purity aluminum alloy. |

| Uneven Thickness | Rolling inaccuracies | Improve process control systems. |

| Poor Surface Finish | Improper annealing | Optimize heat treatment processes. |

The versatile properties of 8079 aluminum foil make it an ideal choice for lid applications across a wide range of industries, providing effective sealing and protection for various products.

In the food industry, maintaining freshness, preventing spoilage, and ensuring food safety are paramount.

8079 aluminum foil lids play a critical role in achieving these objectives for numerous food products:

Yogurt Lids used aluminum foil

8079 aluminum foil is also employed in the beverage industry for sealing various types of containers:

The stringent requirements of the pharmaceutical industry for product integrity and safety make 8079 aluminum foil an invaluable material for lid applications:

8079 aluminum foil for Pharmaceutical Packaging

Beyond food, nápoj, and pharmaceuticals, 8079 aluminum foil finds applications in various industrial packaging:

The diverse applications of 8079 aluminum foil for lids highlight its versatility and the critical role it plays in protecting and preserving a wide array of products across different industries.

The widespread use of 8079 aluminum foil for lids is a testament to the numerous benefits it offers to manufacturers, consumers, and the environment.

Extended Shelf Life

One of the primary advantages of 8079 aluminum foil lids is their exceptional barrier properties.

They effectively block the transmission of moisture, kyslík, osvetlenie, and other gases that can lead to product degradation.

This superior barrier protection significantly extends the shelf life of packaged goods, reducing spoilage and waste, and allowing manufacturers to reach broader markets.

Tamper-Evident Seals

When properly sealed to a container, an 8079 aluminum foil lid provides a robust tamper-evident seal.

Any attempt to open the package will result in visible damage to the foil, clearly indicating to the consumer if the product has been tampered with.

This feature enhances consumer confidence and safety, particularly important for food and pharmaceutical products.

Benefits of Using 8079 Aluminum Foil for Lids

Eco-Friendly and Recyclable

Aluminum is a highly recyclable material, a 8079 aluminum foil is no exception.

Recycling aluminum requires significantly less energy than producing primary aluminum, making it an environmentally sustainable packaging choice.

The high recyclability rate of aluminum contributes to a circular economy and reduces the environmental footprint of packaging.

Cost-Effective

Zatiaľ čo 8079 aluminum foil offers premium performance, it is also a cost-effective packaging solution in the long run.

Its ability to extend shelf life reduces product spoilage, and its lightweight nature can lower transportation costs.

Navyše, the efficient production processes and the value of recycled aluminum contribute to its overall cost-effectiveness.

Versatility for Various Containers

8079 aluminum foil can be used to create lids that can be sealed to a wide variety of container materials, including plastic, glass, and other metals.

This versatility makes it a flexible choice for manufacturers using different packaging formats.

The foil can also be easily formed and shaped to match the specific design of the container.

In summary, the benefits of using 8079 aluminum foil for lids encompass superior product protection, enhanced consumer safety, environmental sustainability, economic efficiency, and broad applicability across different packaging needs.

Selecting the appropriate 8079 aluminum foil for lid applications requires careful consideration of several key factors, including thickness, povlaky, laminácie, and application-specific requirements.

The right choice ensures optimal performance, trvanlivosť, and compliance with industry standards.

Below are the critical aspects to consider when choosing 8079 hliníková fólia pre viečka.

Hrúbka 8079 aluminum foil is a crucial factor that influences sealing performance, mechanical strength, and cost-effectiveness.

The standard thickness range for 8079 aluminum foil used in lid applications is 0.006mm to 0.2mm, with thicker foils providing greater durability and thinner foils offering lightweight and cost advantages.

| Aplikácia | Recommended Thickness | Rationale |

|---|---|---|

| Balenie potravín (Yogurt, Dairy, Ready-to-Eat Meals) | 0.010–0.025 mm | Provides a balance between sealing integrity a flexibilita, zabezpečenie long-term freshness of perishable products. |

| Pharmaceutical Blister Packs | 0.015–0.020 mm | Offers sufficient rigidity to maintain integrity during transportation zatiaľ čo allowing for easy peeling by consumers. |

| Beverage Caps and Jars | 0.018–0.025 mm | Ensures high puncture resistance a secure sealing, preventing leakage and contamination. |

| Cosmetic Jars and Industrial Chemical Packaging | 0.020–0.025 mm | Provides enhanced durability a chemical resistance, suitable for aggressive environments a dlhodobé úložisko. |

When selecting the appropriate thickness, it is essential to consider the mechanical stress the lid will endure during handling, preprava, a úložisko.

Thicker foils are preferred for applications requiring high puncture resistance and structural integrity, while thinner foils are ideal for cost-sensitive and lightweight packaging.

The coating and laminate options for 8079 aluminum foil significantly impact its sealing performance, bariérové vlastnosti, and compatibility with automated packaging systems.

The choice of coating depends on the specific requirements of the application, such as sealing temperature, chemical resistance, and aesthetic considerations.

8079 hliníková fólia pre viečka

Heat-Sealable Coatings

The most common coatings applied to 8079 aluminum foil for lid applications include polyethylene (Pešo), polypropylene (PP), and ethylene-vinyl acetate (EVA).

These coatings provide excellent adhesion to plastic or paper-based packaging materials, ensuring secure and durable seals.

| Náter | Sealing Temperature | Výhody | Žiadosti |

|---|---|---|---|

| Polyethylene (Pešo) | 100–140°C | Excellent flexibility and adhesion, suitable for low-temperature sealing processes. | Balenie potravín, pharmaceutical blister packs. |

| Polypropylene (PP) | 140–160°C | High heat resistance and durability, ideal for high-temperature sealing applications. | Beverage caps, industrial chemical packaging. |

| Ethylene-Vinyl Acetate (EVA) | 110–130°C | Superior flexibility and transparency, often used for visually appealing packaging. | Cosmetic jars, ready-to-eat meals. |

The choice of coating should align with the sealing parameters of the packaging line and the performance requirements of the final product.

Napríklad, PE-coated foils are preferred for low-temperature sealing, while PP-coated foils are suitable for applications requiring high heat resistance.

Barrier Laminates

In addition to heat-sealable coatings, 8079 aluminum foil can be laminated with additional barrier layers to enhance protection against moisture, kyslík, a svetlo.

These laminates are particularly important for products with long shelf life or sensitive formulations.

| Barrier Layer | Funkcia | Žiadosti |

|---|---|---|

| EVOH (Ethylene-Vinyl Alcohol Copolymer) | High oxygen barrier, prevents oxidation of food and pharmaceutical products. | Dairy products, ready-to-eat meals, liquid medications. |

| PVDC (Polyvinylidene Chloride) | Excellent moisture and gas barrier, suitable for high-performance packaging. | Vacuum-sealed food, pharmaceutical blister packs. |

| PET (Polyethylene Terephthalate) | Provides structural support and UV protection, enhances visual appeal. | Cosmetic jars, high-end food packaging. |

Barrier laminates are typically applied using co-extrusion or lamination techniques, ensuring uniform coverage and optimal performance.

The selection of the appropriate barrier layer depends on the specific requirements of the packaged product, such as sensitivity to oxygen, vlhkosť, or light exposure.

The application-specific requirements of the packaging system play a critical role in determining the suitability of 8079 aluminum foil for lid applications.

Factors such as temperature resistance, chemical compatibility, and user experience must be considered to ensure optimal performance and compliance with regulatory standards.

Temperature Resistance

8079 aluminum foil is designed to maintain its structural integrity under both high and low temperature conditions.

The annealed (O-temper) state of 8079 aluminum foil provides maximum flexibility, making it suitable for refrigerated and frozen food packaging.

In contrast, tempered (H22 or H24) foils offer enhanced rigidity, making them ideal for high-temperature applications such as microwaveable food packaging or sterilized pharmaceutical products.

Žiadosti 8079 hliníková fólia pre viečka

Chemical Compatibility

The chemical compatibility of 8079 aluminum foil is essential for applications involving aggressive substances such as acids, základne, or solvents.

The high purity and corrosion resistance of 8079 aluminum ensure minimal interaction with the packaged product, preventing contamination or degradation.

For chemical and pharmaceutical applications, it is advisable to select foils with additional barrier layers to enhance chemical resistance and stability.

Je 8079 aluminum foil food-safe?

Áno, 8079 aluminum foil is food-safe when produced according to Good Manufacturing Practices and relevant food contact regulations.

It is inert and does not typically react with food products. Coatings and lacquers used on the foil must also be food-grade.

Koleno 8079 aluminum foil lids be used for retort sterilization?

Áno, aluminum foil can withstand the high temperatures and pressures involved in retort sterilization processes, tvorba 8079 a suitable material for lids of food products that require such treatment.

The specific performance will depend on the gauge and any coatings or laminates used.

What is the shelf life of 8079 aluminum foil rolls?

When stored in a clean, dry environment and protected from physical damage, 8079 aluminum foil rolls have a long shelf life.

Však, it is best to use the material within the manufacturer’s recommended timeframe to ensure optimal performance of any coatings or laminates.

Koleno 8079 aluminum foil be printed on?

Áno, aluminum foil can be printed on using various printing techniques, such as rotogravure or flexography.

Surface treatments or primer coatings may be necessary to ensure good ink adhesion and high-quality print results.

What is the difference between 8079 and other aluminum alloys used for lids?

Different aluminum alloys have varying chemical compositions, which result in different mechanical and physical properties.

8079 alloy is specifically chosen for lid applications due to its good balance of strength, Formovateľnosť, bariérové vlastnosti, and heat sealability.

Other alloys may be preferred for applications with different requirements.

How should 8079 aluminum foil lids be stored?

To maintain their quality and performance, 8079 aluminum foil lids (whether in roll form or pre-cut) should be stored in a clean, dry area away from extreme temperatures and humidity.

They should also be protected from physical damage or contamination.

Is there a specific side of the 8079 aluminum foil that should be sealed or coated?

Áno, zvyčajne, one side of the aluminum foil is treated or coated with a heat-sealable lacquer that is designed to bond with the container material.

The manufacturer’s specifications should be consulted to ensure the correct side is used for sealing or coating.

How does the thickness of 8079 aluminum foil affect its barrier properties?

Všeobecne, a thicker gauge of aluminum foil will provide a better barrier against moisture, kyslík, and light compared to a thinner gauge of the same alloy.

Však, even thin gauges of aluminum foil offer excellent barrier properties compared to many plastic films.

8079 aluminum foil for lids is a versatile, high-performance material suitable for various industries.

Its superior barrier properties, flexibilita, and eco-friendliness make it the preferred choice for food, nápoj, and pharmaceutical packaging.

By understanding its properties, výrobné procesy, a aplikácie, you can make informed decisions to optimize your packaging needs.

5052 Hliníkový disk je zliatinou Al-Mg známych pre svoju vynikajúcu odolnosť proti korózii, pevnosť s vysokou únavou, a vynikajúca spracovateľnosť.

3004 Hliníkový list je stredne pevná hliníková zliatina s mangánom a horčík ako hlavné legované prvky. Jeho sila je vyššia ako 3003 Hliníkový list, ale ťažnosť je nižšia.

3003 Hliníkové perforované listy sa získavajú dierovaním 3003 Hliníkové zliatiny listov a často sa používajú v architektonickej dekorácii, Stroje na spracovanie potravín a ďalšie polia.

4x8 aluminum sheet is a common size of aluminum sheet, also known as standard size aluminum sheet, referred to as standard sheet.

Hliníkový kruh pre cestnú značku sa týka hliníkového kruhu použitého pri výrobe cestných značiek. Pretože hliníkové kruhy majú silný odolnosť proti korózii a odolnosť proti počasiu, Hliníkové kruhy sú veľmi vhodné na výrobu cestných značiek.

8021 aluminium foil is a common alloy in 8000 hliníkové zliatiny. Common aluminum foils in 8000 series aluminum alloys include 8011 Aluminum Foil and 8079.

Č. 52, Dongmingová cesta, Zhengzhou, Henan, Čína

Henan Huawei Aluminium Co., Došlo, Jeden z najväčších dodávateľov hliníka v Číne Henan,Sme založení v roku 2001 a máme bohaté skúsenosti s dovozom a vývozom a vysokokvalitnými hliníkovými výrobkami

Môj - sat, 8AM - 17:00

Nedeľa: ZATVORENÉ

Č. 52, Dongmingová cesta, Zhengzhou, Henan, Čína

© Autorské práva © 2023 Henan Huawei Aluminium Co., Došlo

Najnovšie komentáre

Drahý pane, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL = 99,50% min) Veľkosť:450 X32 x6 mm. Tvoj 570 Own 1050 A, Množstvo = 3400 kg

Ahoj, Boli by ste tak láskaví ponúknuť položku takto: Cievka 0,6х1250 (1000)mm EN AW-3105 5tons

Ahoj, Môžete mi ponúknuť hliníkové taniere? Konctovo potrebujem: 110mm x 1700 mm x 1700 mm 5083 H111 - 21 pcs Next year planed is 177 počítač

Veľký článok. Bol som potešený, že som hľadal tento článok. Zdá sa, že veľa ľudí, že majú na túto tému spoľahlivé vedomosti, Ale často to tak nie je. Preto moje príjemné prekvapenie. Som ohromený. Toto miesto určite odporučím a spadnem častejšie, Vidieť nové veci.

požiadavka hliníkového pásu