Aluminum alloy welding is a process that involves joining two or more pieces of aluminum together through the use of heat and a filler material. This method of welding has become increasingly popular in a variety of industries due to the numerous advantages it offers.

Aluminum alloys are widely used in various industries due to their excellent properties such as light weight, vysoká sila, superior malleability, Dobrý odolnosť proti korózii, and high thermal conductivity. Však, welding aluminum alloys can be challenging due to their unique metallurgical properties.

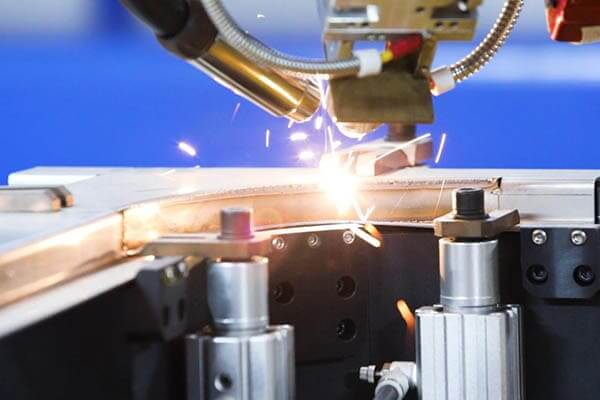

Zváranie hliníkovej zliatiny

Aluminum has a high thermal conductivity and low melting point, which can lead to distortion and burn-through during welding. Aluminum also forms an oxide layer when exposed to air. This oxide layer has a much higher melting point than aluminum, which can cause issues during welding.

There are several welding techniques suitable for aluminum alloys:

Aluminum alloy welding is a process that involves joining two or more pieces of aluminum together through the use of heat and a filler material. This method of welding has become increasingly popular in a variety of industries due to the numerous advantages it offers. In this essay, we will explore some of the key benefits of aluminum alloy welding.

One of the main advantages of aluminum alloy welding is its lightweight nature. Aluminum is a lightweight metal, making it ideal for applications where weight is a concern. By using aluminum alloy welding, manufacturers can create strong and durable structures without adding unnecessary weight. This is particularly important in industries such as aerospace, automobilový, and marine, where weight reduction can lead to increased fuel efficiency and improved performance.

Another advantage of aluminum alloy welding is its high strength-to-weight ratio. Aluminum alloys are known for their excellent strength properties, allowing them to withstand heavy loads and harsh environments. By welding aluminum alloys together, manufacturers can create structures that are both lightweight and strong, making them ideal for a wide range of applications.

Furthermore, aluminum alloy welding offers excellent corrosion resistance. Aluminum is naturally resistant to corrosion, making it a popular choice for outdoor and marine applications. By welding aluminum alloys together, manufacturers can create structures that are highly resistant to rust and corrosion, ensuring their longevity and durability.

In addition to its lightweight nature, high strength-to-weight ratio, a odolnosť proti korózii, aluminum alloy welding also offers excellent thermal conductivity. Aluminum is a good conductor of heat, allowing for efficient heat transfer during the welding process. This results in faster welding speeds and reduced distortion, leading to higher productivity and cost savings.

Moreover, aluminum alloy welding is known for its aesthetic appeal. Aluminum alloys can be easily shaped and formed into intricate designs, making them ideal for applications where aesthetics are important. By welding aluminum alloys together, manufacturers can create visually appealing structures that are both functional and attractive.

In conclusion, aluminum alloy welding offers a wide range of advantages that make it a popular choice in various industries. From its lightweight nature and high strength-to-weight ratio to its corrosion resistance and aesthetic appeal, aluminum alloy welding provides numerous benefits that can improve the performance and longevity of structures. As technology continues to advance, the demand for aluminum alloy welding is expected to grow, making it an essential process for manufacturers looking to create strong, ľahký, and durable structures.

Aluminum alloy welding process

The latest advancements in welding technology for aluminum alloys include:

Please note that the choice of welding technology depends on the specific requirements of the task, including the type of aluminum alloy, the thickness of the material, and the desired properties of the weld. Always consult with a welding professional or refer to the appropriate welding codes and standards for your specific application.

According to TWI Global, some of the precautions you should take when welding aluminum and its alloys are:

Use good shielding practices and parent material/consumable cleanliness to avoid contamination and porosity in the welds.

Select the proper filler metal and welding parameters to minimize the risk of hot cracking, which is a common defect in aluminum welding.

Consider using solid state welding processes such as friction stir welding, which can join aluminum alloys that are difficult to fusion weld.

Navyše, Chief Technology suggests some safety measures for aluminum welding, ako:

Wear protective clothing to shield yourself from potential hazards, such as sparks, spatter, and radiation.

Ensure sufficient ventilation to remove potentially harmful gases, fumes, and smoke, especially ozone, which is produced by the ultraviolet radiation from welding and can cause respiratory issues.

Use appropriate eye and face protection, such as a welding helmet with a suitable shade level, to prevent eye damage and flash burns.

More: https://www.alufoil.cn/blog/aluminum-welding-a-practical-guide.html

Čierna hliníková fólia odolná voči korózii na predaj, Čína Hliníková fólia Výrobca nízka cena propagácie, Farebný dodávateľ hliníkovej fólie eloxovanej fólie

Hliníkový list potiahnutý práškom sa týka hliníkového plechu spracovaného procesom rozprašovania prášku;

8021 aluminium foil is a common alloy in 8000 hliníkové zliatiny. Common aluminum foils in 8000 series aluminum alloys include 8011 Aluminum Foil and 8079.

Náš záväzok k kvalite, rozmanitosť, a prispôsobenie zaisťuje, že nájdete perfektnú izoláciu hliníkovej cievky pre váš projekt.

Hydrofilná hliníková fólia sa získava potiahnutím povrchu hliníkovej fólie hydrofilným povlakom, Účelom je zlepšiť hydrofilný (voda) výkon hliníkovej fólie, a má vyššiu účinnosť prenosu tepla a odolnosť proti korózii.

1100 hliníkový list je jedným zo zástupcov 1 séria čistá hliníková doska, a je to tiež najčastejšie používaná zliatina.

Č. 52, Dongmingová cesta, Zhengzhou, Henan, Čína

Henan Huawei Aluminium Co., Došlo, Jeden z najväčších dodávateľov hliníka v Číne Henan,Sme založení v roku 2001 a máme bohaté skúsenosti s dovozom a vývozom a vysokokvalitnými hliníkovými výrobkami

Môj - sat, 8AM - 17:00

Nedeľa: ZATVORENÉ

Č. 52, Dongmingová cesta, Zhengzhou, Henan, Čína

© Autorské práva © 2023 Henan Huawei Aluminium Co., Došlo

Najnovšie komentáre

Drahý pane, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL = 99,50% min) Veľkosť:450 X32 x6 mm. Tvoj 570 Own 1050 A, Množstvo = 3400 kg

Ahoj, Boli by ste tak láskaví ponúknuť položku takto: Cievka 0,6х1250 (1000)mm EN AW-3105 5tons

Ahoj, Môžete mi ponúknuť hliníkové taniere? Konctovo potrebujem: 110mm x 1700 mm x 1700 mm 5083 H111 - 21 pcs Next year planed is 177 počítač

Veľký článok. Bol som potešený, že som hľadal tento článok. Zdá sa, že veľa ľudí, že majú na túto tému spoľahlivé vedomosti, Ale často to tak nie je. Preto moje príjemné prekvapenie. Som ohromený. Toto miesto určite odporučím a spadnem častejšie, Vidieť nové veci.

požiadavka hliníkového pásu