Ten 6063 Hliníkový list je hliníková zliatina série 6000. Sila 6063 zliatina je nižšia ako v prípade 6061 zliať, A má dobrú extrudovateľnosť, odpor, a dobrý výkon povrchového spracovania.

6063 aluminum sheet is an aluminum alloy with magnesium and silicon as alloying elements. 6063 aluminum sheet generally has good mechanical properties and can be heat treated and welded. The comprehensive performance requirements of aluminum alloy are far higher than the industry standard.

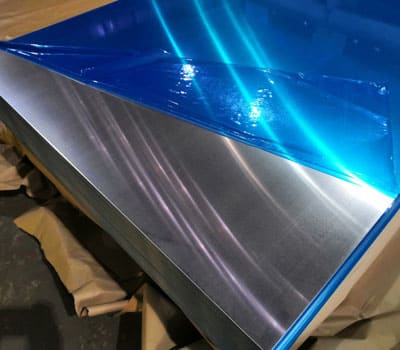

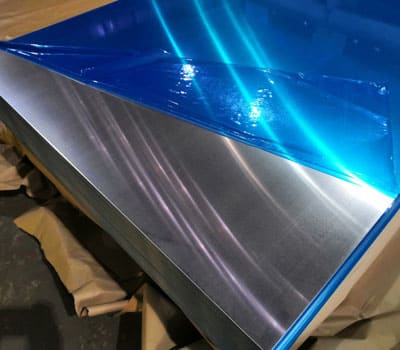

6063 hliníkový plech

Sila 6063 alloy is lower than that of 6061 hliník, A má dobrú extrudovateľnosť, corrosion resistance and good surface treatment performance. 6063 belongs to the low alloy Al-Mg-Si series high plasticity alloy. It has many valuable functions.

| Kremík | Žehlička | Meď | Horčík | Mangán | Chróm | Zinok | Titán | Ďalší | Hliník |

| 0.2~0.6 | 0.35 | 0.1 | 0.45~0.9 | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | Vyvážiť |

The density of 6063 aluminum alloy is 2.69g/cm3.

6063 hliníkový list s modroplňou

The above is about the element composition and element function of 6063 hliníková doska. Shenzhen Wanxing Aluminum Co., Došlo. is a professional agent for sales of Southwest Aluminum, Korean Aluminum, and pure aluminum sheets and alloy sheets wholesaled by our major aluminum factories. With advanced Chinese and English technology and high-quality after-sales service, it is your best candidate.

Several key parameters in the melting and casting process: the furnace temperature is generally set at 1050°C during smelting, and the metal temperature is controlled not to exceed 770°C.

Melting and casting of 6063 hliník

The melting and casting process of 6063 hliníkový list is introduced above. After the material is melted at high temperature, it is directly cast into a product. It is generally dissolved in an electric arc furnace, then poured into high temperature resistant casting, and then cooled to crystallize, annealed or cut into products.

In production, mainly by controlling the melting atmosphere, melting temperature and cooling conditions to ensure high production efficiency, meet the requirements of crystal analysis, and form a network structure.

| Standards | ASTM B209 / ASME SB209 |

| Miernosť | O, T3,T4,T5, T6, T651 T6511 |

| Hrúbka | 0.3-600 mm |

| Šírka | 100-2600 mm |

| Dĺžka | 500-10000 mm |

| Povrch | Jasný, polished, hair line, brush, sand blast, vyrazený, etching, tam. |

| Finish | Mill, Customer specific finish |

| Aluminum Sheet/ Plate Coating | PVC Coated, Color Coated, Polyester, Fluorocarbon, polyurethane and epoxy coating |

| Type | Hot-Rolled (HR) / Cold-Rolled (CR) Pokrývka |

| Hustota | Miesto topenia | Modul elasticity | Elektrický odpor | Tepelná vodivosť | Thermal Expansion |

| 2.69 g/cm3 | 600° C | 69.5 GPA | 0.035×10-6 O.m | 200 W/m.K | 23.5 x 10-6 /K |

| Mechanické vlastnosti | Metrika | Angličtina |

| Konečná pevnosť v ťahu | 241 MPA | 35000 psi |

| Pevnosť v ťahu | 214 MPA | 31000 psi |

| Strih | 152 MPA | 22000 psi |

| Modul elasticity | 68.9 GPA | 10000 ksi |

| Šmykový modul | 25.8 GPA | 3740 ksi |

1. The application of strips is widely used in decoration, balenie, výstavba, preprava, elektronika, letectvo, letectvo, weapons and other industries.

Building use 6063 hliníkový list

2. Aluminum materials for aerospace are used to make aircraft skins, trupové rámy, girders, rotors, propellers, palivové nádrže, wall panels and landing gear pillars, as well as rocket forging rings, spacecraft wall panels, tam.

3. Aluminum materials for transportation are used for car body structural materials of automobiles, subway vehicles, railway passenger cars, high-speed passenger cars, Dvere a okná, shelves, automotive engine parts, air conditioners, radiátory, body panels, wheels and ship materials.

4. Aluminum materials for packaging All-aluminum pop cans are mainly made of thin plates and foils as metal packaging materials to make cans, viečka, fľaše, sudy, a obalové fólie. Widely used in the packaging of beverages, jedlo, cosmetics, medicines, industrial products, tam.

5. Aluminum materials for printing are mainly used to make PS plates. Aluminum-based PS plates are a new type of material for the printing industry and are used for automatic plate making and printing.

6. Aluminum materials for architectural decoration Aluminum alloys have good corrosion resistance, dostatočná sila, excellent process performance and welding performance.

6063 aluminum sheet plate for car

7. Aluminum materials for electronic home appliances are mainly used in various busbars, wiring, dirigent, electrical components, chladničky, air conditioners, cables and other fields. Specifications: Round rods and square rods represent applications including aerospace fixtures, electrical fixtures, and communication fields, and are also widely used in automated mechanical parts, precision machining, mold manufacturing, electronics and precision instruments, SMT, PC board solder carriers, tam.

The 6063-t6 aluminum alloy means that its brand is 6063 zliať, and the retreat process is T6 state. Všeobecne, the yield strength value of T6 state treatment is: 210MPA, and the hardness of 6063-t6 is 73HB.

6063 is a representative product of the high-hardness aluminum plate alloy series, and its hardness can reach 95HB. Súčasne, 6063 aluminum alloy has the advantages of not easy to deform and high strength.

6063 aluminum sheet thickness measurement

The yield strength of 6063-T1 aluminum alloy aluminum plate is: 95Mpa and the hardness is: 42HB.

The yield strength of 6063-T5 aluminum alloy aluminum plate is: 175Mpa and the hardness is: 60HB.

The yield strength of the 6063-T6 aluminum alloy aluminum plate is: 210Mpa and the hardness is: 73HB.

The yield strength of the 6063-T832 aluminum alloy aluminum plate is: 240Mpa and the hardness is: 95HB.

Notes for reference: 10HW hardness corresponds to 120Mpa, 13HW hardness corresponds to 270MPa, you can extrapolate according to the state of the factory you want to know, and compare the reference data.

6063 aluminum sheet has half the strength of aluminum 6061 zliatiny. It is typically produced with very smooth surfaces fit for anodizing and often used to make auto parts, architectural fabrication, window and door frames, aluminium furniture, electronic components as well as various consumer durable products.

| ALLOY | 6061 VS 6063 |

| Chemical Composition | In terms of Mg and SI, 6061 je 30-50% more than 6063. The most direct effect is that 6061 has a greater strengthening effect than 6063. |

| Mechanické vlastnosti | The strengthening effect of 6061 heat treatment is greater. In contrast, the higher the tensile strength, the greater the deformation resistance, so the plasticity of the 6061 alloy is lower than 6063. |

| Plasticity | 6061-T6 is used in occasions that require certain strength and hardness. 6063 is a representative alloy for extrusion with good extrudability. |

| Other Aspects | Ošetrenie povrchom: Both 6061 a 6063 anodizing properties are very good. 6063 aluminum is better.

Machináovateľnosť: Both are good. 6061 is better. Odpor: Both are good. 6063 is slightly better. Zvárateľnosť: 6063 is slightly better. Price: 6063 aluminum sheet price is a little higher than 6061. |

| Záver | Simply speaking, 6061’s advantage is strength, zatiaľ čo 6063 wins in extrudability. |

Ten 5052 Eloxizovaná zrkadlová doska je typ hliníkového plechu, ktorý prešiel anodizačným procesom, čo vedie k reflexnému povrchu. Materiál je vyrobený predovšetkým z 5052 hliník, ktorý je známy svojou vynikajúcou odolnosťou proti korózii a dobrej formnosti.

6061-Hliníková podlahová doska T6, bežne známy ako „diamantová doska“ alebo „behúň“, je vynikajúcim kandidátom pre väčšinu techník spracovania a interiérové aj exteriérové aplikácie.

8021 aluminium foil is a common alloy in 8000 hliníkové zliatiny. Common aluminum foils in 8000 series aluminum alloys include 8011 Aluminum Foil and 8079.

Hliník 8011 Hliníková fólia sa široko používa v hliníkovej plastickej kompozitnej doske Základná páska a obaly potravín. Ako profesionálna hliníková fólia 8011 výrobca v Číne, Hliník Huawei má veľký 8011 základňa výroby hliníkovej fólie a nahromadila viac ako 20 Roky bohatých skúseností s výrobou hliníkovej fólie a kvalifikovanej technológie spracovania.

Ten 1000 Hliníkový list série je séria čistých hliníkových listov. Jeho zloženie je hlavne hliník, s obsahom viac ako 99%.

Výrobca zliatiny profesionálneho hliníka, Priama predajná cena dodávka, Najdôveryhodnejší dodávateľ v Číne Najlepšia cena za predaj

Č. 52, Dongmingová cesta, Zhengzhou, Henan, Čína

Henan Huawei Aluminium Co., Došlo, Jeden z najväčších dodávateľov hliníka v Číne Henan,Sme založení v roku 2001 a máme bohaté skúsenosti s dovozom a vývozom a vysokokvalitnými hliníkovými výrobkami

Môj - sat, 8AM - 17:00

Nedeľa: ZATVORENÉ

© Autorské práva © 2023 Henan Huawei Aluminium Co., Došlo

Najnovšie komentáre

Potrebujem ponuku pre 3000 hliníkové listy/cievky (3104 H19) Pre výrobu tuniaka, povrchová úprava, delivery to Mazatlán, Mexiko.

Plánujem pracovnú cestu do Číny a veľmi ma zaujíma váš hliník 8011 Výrobky pre výrobu nádob na potraviny. Chcel by som navštíviť vašu továreň počas môjho pobytu v Číne: Pozrite sa na svoje výrobné linky (valcovanie fólie, žíhanie, rozrezanie, balenie). Diskutovať o špecifikáciách (8011-O, Hrúbka 0,05–0,08 mm, jumbo rolka). Skontrolujte svoje certifikáty kvality a skúsenosti s exportom. Mohli by ste mi dať vedieť: Your available dates for a visit The location of your factory If you can provide an invitation letter for my business visa (M víza). Ďakujeme za vašu milú podporu. Teším sa na vašu odpoveď. Najlepšia úcta: LOUNIS MUSTAPHA company name:TOP BARQUETTE SELECT [email protected] what's up:213 770 91 69 43

Ahoj ; Burak ünal i. Som úradníkom spoločnosti, ktorá dodáva balenie a čistiace výrobky v Antalya. Tiež robím P.E Stretch Transfer Job. Naše stroje 9 VE 10 Prehodnocujeme prenos hliníkovej fólie mikrónov. Čo od teba chcem, 9 alebo 10 mikrón 35 cm a 45 CM Jumbo Fooys Cena pre Fooy, Term a chcem nasledujúce informácie ; 35 Priemerná hmotnosť cm jumbo fólie. 45 Priemerná hmotnosť cm jumbo fólie. Je to preto, že to bude súd 2 Koľko stojí naša minimálna objednávka tonáž. Užite si svoju prácu.

Sme komerčný výrobca častí a príslušenstva v Egypte nižšie je naše súčasné požiadavky na výrobný proces z hliníkovej cievky (Zliať 1050 hrúbka 0.3 mm width 25cm=10tons width 29.5cm=6tons width 33.5cm=5tons width 37 cm=5tons kindly send us your best quotation ASAP according to our company below details: Nižšie sú uvedené podrobnosti našej spoločnosti : Úplný názov právnej spoločnosti: Zameraný ligth pre priemyselné investície ., Co address: Sprisahanie č 8 - rozšírenie 4. priemyselného priemyslu - zóna Sadat - minofia - egypt Telephone number Ahmed nseem +201016644789 & +201010879400 Moh El Shref : Dav : +2 01016644789 Daňové ID číslo : 699-483-174

Píšem, aby som sa pýtal na produkty, ktoré vaša spoločnosť ponúka. Obzvlášť ma zaujíma produkt uvedený nižšie: *Aluminum Coil QTY-20 Units Could you please provide me with more information on these products, vrátane cien, dostupnosť, a akékoľvek ďalšie podrobnosti, ktoré môžu byť relevantné? a tiež citujte svoju bežnú jednotkovú cenu za dodanie tohto produktu, Spolu so svojou zľavou cenou za objemový nákup plného nákladného vozidla. Poznámka: Ďalej k vyššie uvedenému, Naše štandardné platobné podmienky:Čistá 15 dní do 30 dni od dátumu dodávky faktúry dodávateľa.