Aluminum sheet is a rectangular sheet made by rolling aluminum ingots. Its thickness is usually between 0.1mm and 500mm, and its width can range from more than 200mm to ultra-wide sizes produced by some manufacturers such as 1800mm or even wider. Depending on the use and manufacturing requirements, aluminum sheets can be classified according to alloy composition, thickness, width and length.

Huawei aluminum sheet plate

Aluminum sheets can have the following main types according to different classification standards:

Pure aluminum sheet: made of aluminum with higher purity, such as 1050, 1060, and 1100 aluminum sheet, with a purity of more than 99.5%.

Aluminum alloy sheet: Contains a certain proportion of other metal elements to improve its performance, such as 2000 series (containing copper), 3000 series (containing manganese), 5000 series (containing magnesium), 6000 series (containing magnesium and silicon), 7000 series (containing Zinc) and 8000 series, etc.

Temper-O (annealed state) aluminum sheet: completely annealed, has good plasticity, and is suitable for deep processing such as deep stamping.

Temper-H (work-hardened state) aluminum sheet: After cold work-hardening treatment, it has high strength, including H1x, H2x, H3x and other sub-categories, which respectively represent different degrees of hardening and pre-hardened states.

Temper-T (heat treatment state) aluminum sheet: obtained through solution heat treatment and aging treatment, such as T4, T5, T6, etc., with high strength and hardness.

Thin sheet (0.15mm-2.0mm)

Middle sheet (2.0mm-6.0mm)

Thick sheet (above 6.0mm)

Brushed aluminum sheet

Through mechanical friction, the surface of the aluminum sheet forms a uniform continuous filamentous texture, which has a unique metallic texture and modern feel. It is commonly used in home appliances, electronic products, decorative panels and other fields.

Anodized aluminum sheet

An aluminum sheet is used as an anode for electrochemical reaction in the electrolyte to form a dense oxide film, which improves corrosion resistance and wear resistance, and can be given various colors through coloring treatment. It is widely used in building curtain walls, aerospace components and outdoor products.

Colored Aluminum Oxide sheet

After anodizing, dye adsorption or electrolytic coloring is further carried out to make the oxide film show rich colors and increase the aesthetics and identification.

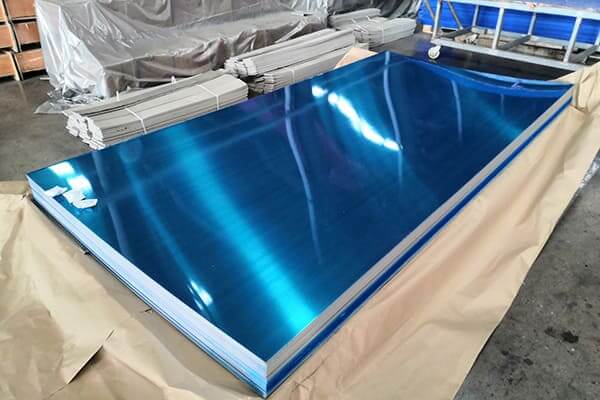

5754 h114 aluminum sheet with bluefilm

Mirror (Polished) aluminum sheet

Through fine polishing, the surface of the aluminum sheet can achieve a mirror-like effect, which is suitable for high-end decoration, furniture manufacturing, lighting reflective materials, etc.

Roller coating (Coating) aluminum sheet

High-quality paint is evenly coated on the surface of the aluminum sheet, and then baked and solidified to form a coating with bright color and strong weather resistance. It is mostly used for building exterior wall decoration, advertising signs, interior decoration, etc. Also called color coated aluminum sheet.

Embossed aluminum sheet

Concave-convex patterns are formed on the surface of aluminum sheets through rolling or stamping to enhance the decorative effect. They are commonly used in packaging, ceilings, curtain wall decoration and other purposes.

Aluminum sheets are widely used in many industries and fields because of their light weight, high strength, corrosion resistance, recyclability, and excellent electrical and thermal conductivity. Here are some of the main uses:

Exterior wall decoration materials: aluminum-plastic composite panels, curtain wall systems, roof materials, etc.

Interior decoration: ceilings, wall decorations, partitions, interior doors, furniture surfaces, etc.

Lighting fixtures: lampshades, reflectors, etc.

Automobile manufacturing: body panels, chassis parts, wheels, radiators, etc.

Aerospace industry: aircraft fuselage, wing skin, internal structural parts, etc.

Manufacture of hull, deck and cabin structures, especially for high-speed craft and luxury yachts, taking advantage of their lightweight and corrosion-resistant properties.

Electronic product casings: such as mobile phone cases, laptop casings, TV frames, etc.

Radiators and heaters: used for thermal management of electronic equipment.

Medical device components: such as surgical instruments, medical bed frames, infusion bottles, X-ray film holders, etc.

Household appliance casing: the casing and internal structure of refrigerators, washing machines, air conditioners, microwave ovens and other household appliances.

Signboards, publicity boards, exhibition display equipment, advertising light boxes, etc.

Aluminum alloy furniture panels, cabinet door panels, office desks and chairs and other modern minimalist style furniture components.

What is aluminum sheet used for

Mechanical parts, mold manufacturing, chemical pipeline coating, protective covers, etc.

Frames, brackets and reflectors for solar panels.

High-speed rail carriage interior and exterior decoration, rail transit vehicle structural parts, etc.

Different series of aluminum sheets, such as JIS A.A 1000 series pure aluminum sheets, are used in fields suitable for their characteristics due to their different compositions and performance characteristics. For example, aluminum sheets with higher purity are suitable for applications that require high electrical conductivity and corrosion resistance, while aluminum alloy sheets with other alloying elements added may be more suitable for areas that require higher strength or specific mechanical properties.

Common aluminium disc circle for lamps are 1050-O, 1060-O, 1100-O, etc., because the lampshade is obtained by stamping aluminum discs, and the O-state aluminum discs have better ductility and are more suitable for stamping treatment;

Henan Huawei Aluminum provides jumbo rolls of household aluminum foil, 8011 alloy, 1235 alloy Household Aluminum foil application for barbecue, food wrapping, etc.

Diamond aluminum sheet is a type of aluminum sheet that features a raised diamond pattern on one side, which provides excellent slip resistance and traction in wet and slippery conditions.

Our commitment to quality, variety, and customization ensures that you'll find the perfect insulation aluminum coil for your project.

5×10 aluminum sheet is a common specification of aluminum sheet produced by aluminum sheet manufacturers,it is 5 feet wide and 10 feet long.

1050 aluminum strips belongs to the family of commercially pure malleable 1000 series alloys, and the aluminum is 99 pure. 5%, with excellent molding processing characteristics, high corrosion resistance, good electrical and thermal conductivity.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip