Composite aluminum foil is a functional material composed of aluminum foil and other materials. It has various properties such as antioxidant, heat resistance, corrosion resistance, and heat insulation

Composite aluminum foil is a functional material composed of aluminum foil and other materials. It has various properties such as antioxidant, heat resistance, corrosion resistance, and heat insulation, and is widely used in industry, construction, food packaging and other fields.

As a common material, aluminum foil is light, thin, flexible, effectively blocks ultraviolet rays and high temperatures, and has good thermal conductivity. Use aluminum foil in combination with other materials to bring into play their respective advantages and improve overall performance.

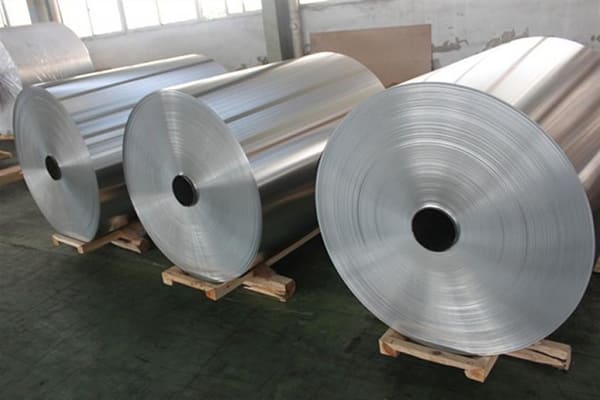

composite aluminum foil

PET is the abbreviation of “Polyethylene Terephthalate”, a common thermoplastic polymer and a member of the polyester family. PET materials are widely used worldwide, especially in the fields of packaging, fibers and engineering plastics.

When compounded with aluminum foil, PET materials can provide good mechanical properties, such as stiffness, impact resistance and abrasion resistance; while aluminum foil provides excellent barrier properties, such as preventing oxygen, moisture and light penetration. This PET/aluminum foil composite material is often used in the packaging of high-end food, pharmaceuticals and chemical products to ensure product shelf life and stable quality. In addition, PET can also be combined with multi-layer films to make heat shrink films, label films and other functional packaging materials.

PE refers to “Polyethylene”, which is a very common synthetic resin. It is a high molecular polymer and is made by polymerizing ethylene monomer. Polyethylene is widely used around the world due to its excellent physical properties and chemical stability.

Polyethylene can be divided into various types based on molecular weight, crystallinity and branched chain structure, such as:

Low-density polyethylene (LDPE, Low-Density Polyethylene):

It has good flexibility, ductility and transparency, and is commonly used in plastic bags, plastic wrap, agricultural mulch films, flexible pipes and other products.

Linear Low-Density Polyethylene (LLDPE, Linear Low-Density Polyethylene):

Compared with LDPE, it is more linear in structure, has stronger mechanical properties, and is slightly less transparent. It is widely used in plastic films, plastic bags, pipes, cable insulation materials and other fields.

High-density polyethylene (HDPE, High-Density Polyethylene):

It has high strength, hardness and wear resistance, and is relatively heat-resistant. It is mainly used to make bottles (such as dish soap bottles, milk bottles), buckets, toys, water pipes, large containers, non-food grade packaging and various industries. Parts etc.

Ultra-High Molecular Weight Polyethylene (UHMWPE, Ultra-High Molecular Weight Polyethylene):

It has extremely high impact strength, self-lubrication and wear resistance, and is mainly used in products with high performance requirements, such as bulletproof materials, skating rink panels, artificial joints, marine cables and high-end sports equipment parts.

PE (polyethylene) and aluminum foil composite is to combine polyethylene film and aluminum foil through adhesive or other composite technology to form a composite material with a variety of excellent properties. This composite material combines the advantages of PE and aluminum foil

PVC is the abbreviation of “Polyvinyl Chloride”, which is a common synthetic polymer material produced by the addition polymerization of vinyl chloride monomer (VCM). PVC has a wide range of uses, especially in the fields of construction, packaging, wires and cables, medical equipment, furniture decoration, etc.

PVC (polyvinyl chloride) and aluminum foil composite refers to bonding PVC material and aluminum foil together through a specific process to form a composite material with multiple properties. This PVC aluminum foil composite material combines the advantages of both materials.

EPE is the abbreviation of “Expanded Polyethylene”, also known as pearl cotton, which is a new type of environmentally friendly packaging material. It uses a physical foaming process to heat low-density polyethylene (LDPE) and add a foaming agent. It is extruded by an extruder and then cooled and shaped to form numerous independent closed-cell foam materials.

EPE material and aluminum foil are bonded together through a special process to form a new packaging or insulation material with dual performance advantages. EPE usually takes the form of pearl cotton, which is lightweight, soft, elastic, and shock-absorbing. It is widely used as cushioning packaging and filling materials for various products.

composite-aluminum-foil-production

Common alloys used to make aluminum foil mainly include the following:

aluminum foil packaged

There are several main reasons for the composite use of aluminum foil and other materials:

Therefore, these advantages of composite aluminum foil are exactly the problems that traditional battery aluminum foil urgently needs to solve. With the development of new energy and the penetration of downstream application scenarios, composite aluminum foil is expected to replace traditional battery aluminum foil and even extend to more other fields, becoming the next blue ocean of new materials.

Composite aluminum foil is a functional material made of aluminum foil and other materials. It has various properties such as antioxidant, heat resistance, corrosion resistance, and heat insulation. It is widely used in industry, construction, food packaging and other fields.

As a common material for composite materials, aluminum foil has the advantages of being light, thin, and flexible. It can effectively block ultraviolet rays and high temperatures, and also has good thermal conductivity. Therefore, the composite use of aluminum foil with other materials can bring into play their respective advantages and improve the overall performance of the material.

packaging used composite aluminum foil

In the field of food packaging, composite aluminum foil is widely used. Due to the antioxidant properties of aluminum junctions, it can well protect food from the influence of the external environment and extend the shelf life. At the same time, composite aluminum foil can effectively isolate the transmission of oxygen, moisture and taste, maintaining the taste and texture of food. In addition, aluminum foil also has good thermal conductivity and can quickly dissipate heat, allowing the food to cool quickly during the packaging process.

In the field of construction, aluminum box composite materials are often used as thermal insulation materials. Due to the heat resistance of the aluminum box, it can effectively isolate the indoor and outdoor temperature differences, reduce energy transmission losses and improve the energy-saving performance of the building. In addition, aluminum foil also has good anti-corrosion properties, which can prevent rain and chemicals in the air from corroding building materials and extend the service life of the building.

In the industrial field, composite aluminum foil is often used in the packaging of electronic products. Because the aluminum junction has good electrical conductivity, it can effectively shield electromagnetic radiation and protect the normal operation of electronic products. At the same time, aluminum foil also has good antioxidant properties, which can prevent oxidation from damaging electronic components.

In short, composite aluminum foil, as a functional material, is widely used in food packaging, construction, electronic products and other fields. Its advantages include light flexibility, hydrogenation resistance, heat resistance, heat insulation and corrosion resistance. It can effectively improve the overall performance of the material and meet the needs of materials in different fields.

Composite aluminum foil bags are made of aluminum and other high-barrier materials after dry compounding. Material: PET/NY/AL/PE (general packaging) PET/NY/AL/CPP (high temperature cooking); VMPET/CPE or PET/AL/NY/CPE (anti-static shielding bag). Thickness: 70~180, micron: generally customized according to customer requirements, bag shape: three-side sealing, self-standing zipper bag, yin and yang bag, center sealing organ. Product use: cosmetics, facial masks, medicinal materials, medicines, various solutions, various foods, various PC boards, IC integrated circuits, optical drives, hard drives, LCD electronic components, welding materials, electronic products, circuit boards, etc. Food packaging films, medicinal packaging films, pesticide packaging films, seed packaging films, industrial product packaging films, facial mask packaging films, solid packaging films, etc. on the market are all composite aluminum foil bags.

The characteristics of composite aluminum foil bags include: PET: good printing effect; N Y: low oxygen permeability; A L: strong barrier and opaque; P E: ordinary packaging inner layer; CPP: high-temperature cooking inner layer. The advantages include: strong air barrier performance, anti-oxidation, waterproof and moisture-proof; strong mechanical properties, high blast resistance, puncture resistance and tear resistance; high temperature resistance (121℃), low temperature resistance (-50℃), oil resistance, It has good fragrance retention performance; it is non-toxic and odorless, and meets the hygienic standards for food and drug packaging; it has good heat sealing performance, softness and high barrier properties.

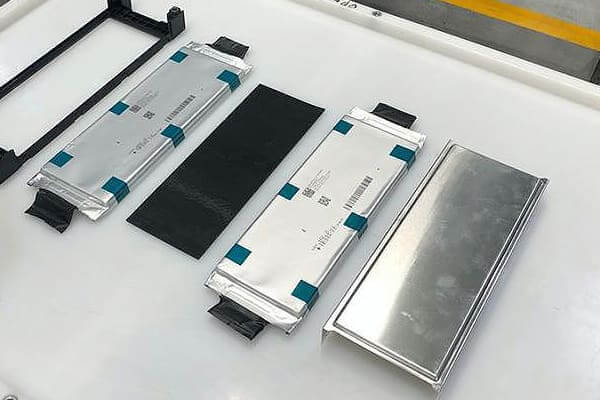

Although the market demand for battery aluminum foil is strong, as a key auxiliary material for batteries, it also needs to face safety and battery life issues. Composite aluminum foil can solve these problems.

Composite aluminum foil is a new type of composite foil that uses organic polymer materials such as polymer PET as a support layer, deposits metal aluminum on its surface, and plating it into a sandwich structure of “aluminum-PET polymer material support layer-aluminum”. Batteries made from this material have the characteristics of high safety and high energy density.

These advantages of composite aluminum foil are exactly the problems that traditional battery aluminum foil urgently needs to solve. With the development of new energy and the penetration of downstream application scenarios, composite aluminum foil is expected to replace traditional battery aluminum foil and even extend to more other fields, becoming the next blue ocean of new materials.

composite aluminum foil for battery

Different from the traditional battery aluminum foil rolling preparation process, the composite aluminum foil vacuum coating equipment mainly deposits directly on the surface of the organic film through vacuum evaporation method, so that the metal aluminum layer finally reaches the required thickness to meet the technical requirements of the battery current collector. The preparation of composite aluminum foil adopts a full vacuum deposition process, which is simpler, has no pollution in the production process, and has no requirements for environmental protection qualifications. It is a truly all-dry environmentally friendly process.

Pearl cotton composite aluminum foil is composed of pearl cotton and aluminum foil. There are many names, such as: pearl cotton composite aluminum film, aluminum foil moisture-proof floor mat, aluminum composite film pearl cotton, etc. Compared with other pearl cotton composite products, the practical function of pearl cotton composite aluminum foil is relatively single. But in terms of global warming and the continued high temperature weather this summer, it is a very effective insulation material! After being combined with pearl cotton, it combines the best of both worlds and is shockproof, waterproof, moisture-proof, dustproof and non-toxic.

EPE composite aluminum foil

Application fields: The demand for pearl cotton composite aluminum film has increased sharply in recent years. It is usually used as a decoration material for inner walls of buildings and indoor furniture. It is also widely used in facades and interior decoration of commercial institutions, especially in packaging, mechanical and electrical and construction industries. Large areas have become essential. The composite aluminum film market is not large horizontally, but it can extend the industrial chain vertically and process aluminum foil materials into end products. The high added value of the products can offset the lack of professional market capacity. Relying on the competitive advantages of professional brands, it can still Obtain better operating benefits.

5005 aluminum coil refers to the 5005 aluminum plate after being cast and rolled and then processed into a coil shape by drawing and bending,

Get premium 3004 aluminum foil Dubai, perfect for packaging, construction, and industrial applications. Lightweight, corrosion-resistant, and highly durable!

1050 aluminum strips belongs to the family of commercially pure malleable 1000 series alloys, and the aluminum is 99 pure. 5%, with excellent molding processing characteristics, high corrosion resistance, good electrical and thermal conductivity.

5754 aluminum sheet has the characteristics of excellent processability, good corrosion resistance, weldability and easy forming. As a wrought alloy, 5754 aluminum sheet can be formed by rolling, extrusion, and forging, but not by casting.

Pharmaceutical foil, also known as medical-grade foil or blister foil, 8011,8021,8079 aluminum foil common used for Pharmaceutical packaging foil.

Contact us today to learn more about our 5083 aluminum coil offerings and how we can meet your specific requirements.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

I need a quotation for 3000 series aluminum sheets/coils (3104 H19) for tuna can production, food-grade finish, delivery to Mazatlán, Mexico.

I am planning a business trip to China and I am very interested in your aluminium 8011 products for food container production. I would like to visit your factory during my stay in china: See your production lines (foil rolling, annealing, slitting, packing). Discuss specifications (8011-O temper, thickness 0.05–0.08 mm, jumbo roll). Review your quality certificates and export experience. Could you please let me know: Your available dates for a visit The location of your factory If you can provide an invitation letter for my business visa (M visa). Thank you for your kind support. Looking forward to your reply. Best regard: LOUNIS MUSTAPHA company name:TOP BARQUETTE SELECT [email protected] what's up:213 770 91 69 43

Merhaba ; Burak ÜNAL ben. Antalya ' da Ambalaj ve Temizlik ürünleri tedarik eden bir firmanın yetkilisiyim. Ayrıca P.E Streç aktarım işi yapmaktayım. Makinalarımızı 9 ve 10 micron alüminyum folyo aktarımına uyacak şekilde revize edeceğiz. Sizden istediğim, 9 veya 10 micron olacak şekilde 35 cm ve 45 cm jumbo folyolar için fiyat, termin ve şu bilgileri istiyorum ; 35 cm jumbo folyonun ortalama ağırlığı. 45 cm jumbo folyonun ortalama ağırlığı. Deneme olacağı için bu 2 ölçüde minimum sipariş tonajımız ne kadar olması gereklidir. İyi çalışmalar.

We are A Commercial Lighting 's parts and accessories Manufacturer in egypt below is our current requirements for production process from aluminum coil (Alloy 1050 temper O thickness 0.3 mm width 25cm=10tons width 29.5cm=6tons width 33.5cm=5tons width 37 cm=5tons kindly send us your best quotation ASAP according to our company below details: Below is our company details : Full legal company name: Focused ligth for industrial investment ., Co address: Plot no 8 - extension of 4th industrial - zone sadat - minofia - egypt Telephone number Ahmed nseem +201016644789 & +201010879400 Eng Moh El shrief : Mob : +2 01016644789 Tax ID number : 699-483-174

I am writing to inquire about the products that your company offers. I am particularly interested in the product listed below: *Aluminum Coil QTY-20 Units Could you please provide me with more information on these products, including pricing, availability, and any additional details that may be relevant? and also quote your ordinary unit price for supplying these product, together with your discount price for the volume purchase of full truck load. Note: Additionally to the above, our standard Payment Terms:Net 15days to 30 days from the date of supply with the supplier's Invoice.