5754 aluminum sheet has the characteristics of excellent processability, good corrosion resistance, weldability and easy forming. As a wrought alloy, 5754 aluminum sheet can be formed by rolling, extrusion, and forging, but not by casting.

5754 aluminum sheet has the characteristics of excellent processability, good corrosion resistance, weldability and easy forming. As a wrought alloy, 5754 aluminum sheet can be formed by rolling, extrusion, and forging, but not by casting.

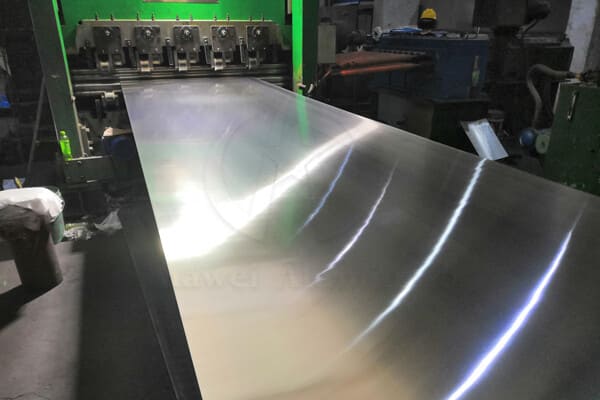

5754 aluminum sheet

5754 aluminum alloy is a typical Al-Mg alloy, containing 2,6-3,6% magnesium, commonly referred to as “AlMg3”. It is an aluminum alloy with magnesium as the main alloying element and small additions of chromium and/or manganese.

Commonly tempered states of the material are 5754-H111 and 5754 H22, H12, H14, H114, etc. In the fully soft annealed state, it has good formability and can be work hardened to high strength levels. It is slightly stronger than 5052 alloy aluminum sheet, but less ductile.

Al 5754 has high strength resistance, excellent resistance to atmospheric and marine corrosion, excellent weldability, suitable for anodizing protection. 5754 alloy is widely used in automotive body panels and frames, railways, ships (plates), electric power, transportation tanks, chemicals, food, forging and other industrial fields. Before being used in the automotive and aerospace industries, this aluminum alloy must be anodized for high microhardness.

| Si | Fe | Cu | Mn+Cr | Mg | Zn | Ti | Others-Each | Others Total | Al Min |

| 0.40 | 0.40 | 0.10 | 0.10-0.6 | 2.6-3.6 | 0.20 | – | 0.05 | 0.15 | Remainder |

Data Sources:https://en.wikipedia.org/wiki/5754_aluminium_alloy

5754 aluminum sheet has the characteristics of excellent processing performance, good corrosion resistance, weldability and easy forming. As a wrought alloy, 5754 aluminum sheet can be formed by rolling, extrusion and forging, but not by casting.

Aluminum 5754 has excellent corrosion resistance, especially to seawater and industrially polluted atmosphere. Its strength is higher than 5251. This high strength makes 5754 aluminum sheet ideal for flooring applications.

1.5mm 5754-h111 aluminum sheet

5754 aluminum plate, also known as 3.3535 aluminum plate, is a typical representative product of aluminum-magnesium alloy. Its magnesium alloy content is higher than that of 5052 aluminum plate. It is also an ideal material for making oil tankers.

Aluminum 5754 has been used in the aviation industry since the late 1940s and is still widely used in the aviation industry today. It is characterized by good plasticity after solution treatment, excellent heat treatment strengthening effect, high strength below 150 °C, and excellent low temperature strength.

Pressure Vessel With 5754 Aluminum Sheet

In recent years, 5754 aluminum has been widely used in the mold industry. Many molds with high strength requirements choose 6061 aluminum plate under unsatisfactory conditions, which can prolong the service life of the mold and reduce the cost of the enterprise. Commonly used in welded structures, storage tanks, pressure vessels, ship structures and offshore facilities, transport tanks, etc.

5754 aluminum plate has good corrosion resistance, excellent workability and weldability, and is easy to process and form. 5754 aluminum in various states is used as raw material for doors, molds, seals and cans.

| Physical Property | Value |

| Density | 2.66 g/cm³ |

| Melting Point | 600 °C |

| Thermal Expansion | 24 x10^-6 /K |

| Modulus of Elasticity | 68 GPa |

| Thermal Conductivity | 147 W/m.K |

| Electrical Resistivity | 0.049 x10^-6 Ω .m |

| European | Germany | US | ISO | Japan | Australia | China |

| Numeric (Chemical Symbols) |

Designation (material number) |

AA (UNS) | Aluminium | Aluminium | Aluminium | Aluminium |

| EN AW-5754 (AlMg3) |

AlMg3 (3.3535) | 5754 (UNS A95754) |

AW-5754 | 5754 | 5754 | 5754 |

Packaged 5754 Aluminum Sheet

The grades are H111, H114, H22, H24, H26. The two main differences that depend on tempering are strength and hardness. So for example, compared with H111 and H26, H26 is stronger, the maximum tensile strength of H111 is 200, while H26 is 305. This means that H26 will be more suitable for applications requiring higher strength and impact resistance, while H111 may be more suitable for applications requiring forming.

| Temper | Thickness | Yield Strength | Tensile Strength | Elongation | Hardness1) | |

| Rp0.2 | Rm | A50 | A | |||

| [mm] | [N/mm2] | [N/mm2] | [%] | [%] | HBW | |

| O/H111 | > 0.2–0.5 | ≥ 80 | 190–240 | ≥ 12 | – | 52 |

| > 0.5–1.5 | ≥ 80 | 190–240 | ≥ 14 | – | 52 | |

| > 1.5–3.0 | ≥ 80 | 190–240 | ≥ 16 | – | 52 | |

| > 3.0–12.5 | ≥ 80 | 190–240 | ≥ 18 | – | 52 | |

| > 12.5–100.0 | ≥ 80 | 190–240 | – | ≥ 17 | 52 | |

| H112 | ≥ 6.0–12.5 | ≥ 100 | ≥ 190 | ≥ 12 | – | 62 |

| > 12.5–25.0 | ≥ 90 | ≥ 190 | – | ≥ 10 | 58 | |

| > 25.0–40.0 | ≥ 80 | ≥ 190 | – | ≥ 12 | 52 | |

| > 40.0–80.0 | ≥ 80 | ≥ 190 | – | ≥ 14 | 52 | |

| H12 | > 0.2–0.5 | ≥ 170 | 220–270 | ≥ 4 | – | 66 |

| > 0.5–1.5 | ≥ 170 | 220–270 | ≥ 5 | – | 66 | |

| > 1.5–3.0 | ≥ 170 | 220–270 | ≥ 6 | – | 66 | |

| > 3.0–6.0 | ≥ 170 | 220–270 | ≥ 7 | – | 66 | |

| > 6.0–12.5 | ≥ 170 | 220–270 | ≥ 9 | – | 66 | |

| > 12.5–40.0 | ≥ 170 | 220–270 | – | ≥ 9 | 66 | |

| H14 | > 0.2–1.5 | ≥ 190 | 240–280 | ≥ 3 | – | 72 |

| > 1.5–6.0 | ≥ 190 | 240–280 | ≥ 4 | – | 72 | |

| > 6.0–12.5 | ≥ 190 | 240–280 | ≥ 5 | – | 72 | |

| > 12.5–25.0 | ≥ 190 | 240–280 | – | ≥ 6 | 72 | |

| H16 | > 0.2–0.5 | ≥ 220 | 265–305 | ≥ 2 | – | 80 |

| > 0.5–6.0 | ≥ 205 | 265–305 | ≥ 3 | – | 80 | |

| H18 | > 0.2–0.5 | ≥ 250 | ≥ 290 | ≥ 1 | – | 88 |

| > 0.5–3.0 | ≥ 250 | ≥ 290 | ≥ 2 | – | 88 | |

| H22/H32 | > 0.2–0.5 | ≥ 130 | 220–270 | ≥ 7 | – | 63 |

| > 0.5–1.5 | ≥ 130 | 220–270 | ≥ 8 | – | 63 | |

| > 1.5–3.0 | ≥ 130 | 220–270 | ≥ 10 | – | 63 | |

| > 3.0–6.0 | ≥ 130 | 220–270 | ≥ 11 | – | 63 | |

| > 6.0–12.5 | ≥ 130 | 220–270 | ≥ 10 | – | 63 | |

| > 12.5–40.0 | ≥ 130 | 220–270 | – | ≥ 9 | 63 | |

| H24/H34 | > 0.2–1.5 | ≥ 160 | 240–280 | ≥ 6 | – | 70 |

| > 1.5–3.0 | ≥ 160 | 240–280 | ≥ 7 | – | 70 | |

| > 3.0–6.0 | ≥ 160 | 240–280 | ≥ 8 | – | 70 | |

| > 6.0–12.5 | ≥ 160 | 240–280 | ≥ 10 | – | 70 | |

| > 12.5–25.0 | ≥ 160 | 240–280 | – | ≥ 8 | 70 | |

| H26/H36 | > 0.2–1.5 | ≥ 190 | 265–305 | ≥ 4 | – | 78 |

| > 1.5–3.0 | ≥ 190 | 265–305 | ≥ 5 | – | 78 | |

| > 3.0–6.0 | ≥ 190 | 265–305 | ≥ 6 | – | 78 | |

| H28/H38 | > 0.2–1.5 | ≥ 230 | ≥ 290 | ≥ 3 | – | 87 |

| > 1.5–3.0 | ≥ 230 | ≥ 290 | ≥ 4 | – | 87 | |

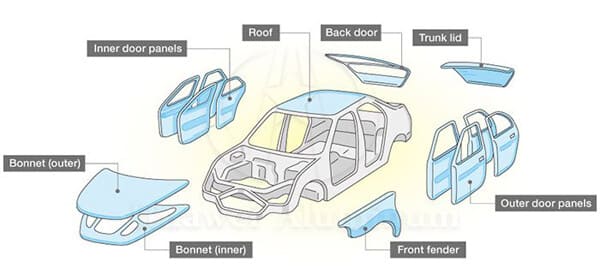

5754 aluminum is typically used for:

Roof Panels: Reducing the weight of the roof (i.e. lowering the center of gravity) has always been a high priority in car design. In all-aluminum body designs, the use of aluminum for the roof is common.

Engine Bottom Guard: It serves two purposes: protecting the engine and improving airflow to the vehicle chassis. 5754 aluminum plate is a good choice.

5754 Aluminum Used In Car Parts

Car doors: Aluminum alloys used for car doors should have high fatigue resistance and excellent corrosion resistance, as well as excellent processability. The use of 5754 aluminum plate can bring a more comfortable feeling, the door closing sound is light, and the door lock is safe.

Fuel tank: Common aluminum alloys for fuel tanks on the market include 5052, 3003, and 5754 aluminum plates. It can effectively extend the life of the car’s fuel tank, so it replaces the traditional iron fuel tank and plastic fuel tank.

The Uses of 5754 Aluminum in Car

Oil tanker: The tank body made of 5754 aluminum plate can not only meet the requirements of lightweight, but also greatly improve the safety performance and eliminate hidden dangers.

Q:What makes 5754 aluminum suitable for marine applications?

A:This grade is resistant to salt water corrosion, ensuring that the aluminum can withstand frequent exposure to marine environments without spoiling or rusting.

Q: Why is this grade of aluminum widely used in the automotive industry?

A: This grade of aluminium exhibits good drawability and maintains high strength. It can be easily soldered and anodized for an excellent surface finish. Due to its ease of forming and machining, this grade is suitable for doors, panels, floors and other parts.

Q:What Is Your MOQ?

A: The MOQ of each specification is 8 tons. If your order is less than 8 tons, welcome to contact us directly. We will help you to check the aluminum sheets in stock.

Q:Is your 5754 aluminum sheet price fixed?

A: The 5754 aluminium sheet price consists of aluminum ingot price and processing fees. As the price of aluminum ingots fluctuates daily, the quotation will fluctuate.

Huawei Aluminum is your reliable partner for 1070 Aluminum Coil products. With our commitment to quality, customization, and competitive pricing, we aim to meet and exceed your expectations.

Aluminium circle for cookwares typically refers to a circular-shaped piece or circle made from aluminum that is used in the manufacturing of various types of cookware, such as pots, pans, and cooking utensils.

7075 aluminum sheet is the strongest heat-treatable alloy, introduced by Alcoa in 1943, and can be heat-treated to achieve strength levels comparable to many steel alloys.

3004 aluminium circle ,also named 3004 aluminium disc,3004 aluminium disk, it is made by stamping 3004 aluminium coils.

If you are looking for top-quality prepainted aluminum coils with various alloy models and specifications, Huawei Aluminum is your ultimate choice.

8021 aluminum foil has the characteristics of cleanliness and hygiene, and can be made into an integrated packaging material with many other packaging materials. In addition, the surface printing effect of 8021 aluminum foil is better than other materials. Therefore, 8021 aluminum foil alloy can also be used in the field of food packaging.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

I need a quotation for 3000 series aluminum sheets/coils (3104 H19) for tuna can production, food-grade finish, delivery to Mazatlán, Mexico.

I am planning a business trip to China and I am very interested in your aluminium 8011 products for food container production. I would like to visit your factory during my stay in china: See your production lines (foil rolling, annealing, slitting, packing). Discuss specifications (8011-O temper, thickness 0.05–0.08 mm, jumbo roll). Review your quality certificates and export experience. Could you please let me know: Your available dates for a visit The location of your factory If you can provide an invitation letter for my business visa (M visa). Thank you for your kind support. Looking forward to your reply. Best regard: LOUNIS MUSTAPHA company name:TOP BARQUETTE SELECT [email protected] what's up:213 770 91 69 43

Merhaba ; Burak ÜNAL ben. Antalya ' da Ambalaj ve Temizlik ürünleri tedarik eden bir firmanın yetkilisiyim. Ayrıca P.E Streç aktarım işi yapmaktayım. Makinalarımızı 9 ve 10 micron alüminyum folyo aktarımına uyacak şekilde revize edeceğiz. Sizden istediğim, 9 veya 10 micron olacak şekilde 35 cm ve 45 cm jumbo folyolar için fiyat, termin ve şu bilgileri istiyorum ; 35 cm jumbo folyonun ortalama ağırlığı. 45 cm jumbo folyonun ortalama ağırlığı. Deneme olacağı için bu 2 ölçüde minimum sipariş tonajımız ne kadar olması gereklidir. İyi çalışmalar.

We are A Commercial Lighting 's parts and accessories Manufacturer in egypt below is our current requirements for production process from aluminum coil (Alloy 1050 temper O thickness 0.3 mm width 25cm=10tons width 29.5cm=6tons width 33.5cm=5tons width 37 cm=5tons kindly send us your best quotation ASAP according to our company below details: Below is our company details : Full legal company name: Focused ligth for industrial investment ., Co address: Plot no 8 - extension of 4th industrial - zone sadat - minofia - egypt Telephone number Ahmed nseem +201016644789 & +201010879400 Eng Moh El shrief : Mob : +2 01016644789 Tax ID number : 699-483-174

I am writing to inquire about the products that your company offers. I am particularly interested in the product listed below: *Aluminum Coil QTY-20 Units Could you please provide me with more information on these products, including pricing, availability, and any additional details that may be relevant? and also quote your ordinary unit price for supplying these product, together with your discount price for the volume purchase of full truck load. Note: Additionally to the above, our standard Payment Terms:Net 15days to 30 days from the date of supply with the supplier's Invoice.