5052 aluminum sheet is part of the 5000 series of aluminum. The grades in this series are alloyed with magnesium (2.5%) and have medium to high strength properties.

5052 aluminum sheet is part of the 5000 series of aluminum. The grades in this series are alloyed with magnesium (2.5%) and have medium to high strength properties.

5052 aluminum is considered to have good weldability and corrosion resistance. 5052 aluminum also contains 0.25% chromium.

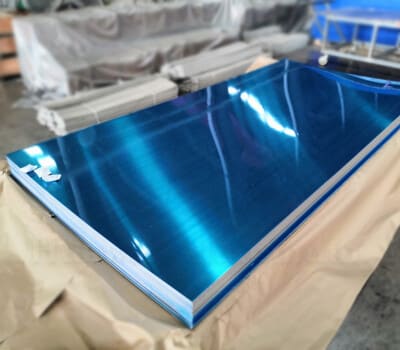

5052 Aluminum Sheet Surface Display

5052 aluminum contains no copper, so it is less susceptible to salt water corrosion than copper-containing alloys.

5052 aluminum plate is a non-heat treatable aluminum alloy with excellent surface finish quality.

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: Each |

Others: Total |

Al: Min. |

| 0.25 | 0.40 | 0.10 | 0.10 | 2.2~2.8 | 0.15~0.35 | 0.10 | – | 0.05 | 0.15 | remainder |

Table Resource: 5052 aluminum sheet

Henan Huawei Aluminum Co., Ltd, a privately-owned enterprises established in 2001, is located in Huiguo Town which is the famous Aluminum Capital in Henan Province, China.

We have a production workshop of more than 100,000 square meters, have accumulated mature technology and experience in production and sales, and have established long-term and stable cooperation with more than 60 countries in the world.

For many years, before the advent of 5083 and 5086, 5052 alloy aluminum was the strongest non-heat treatable alloy on the market.

5052 alloy aluminum sheet is cold work hardened and has good formability and good corrosion resistance, including salt water resistance.

5052 Aluminum Sheet For Boat

Aluminum sheet 5052 can be easily welded using a variety of techniques. It offers some of the best welding characteristics of any aluminum alloy and, while easy to weld, is not recommended for brazing and soldering applications.

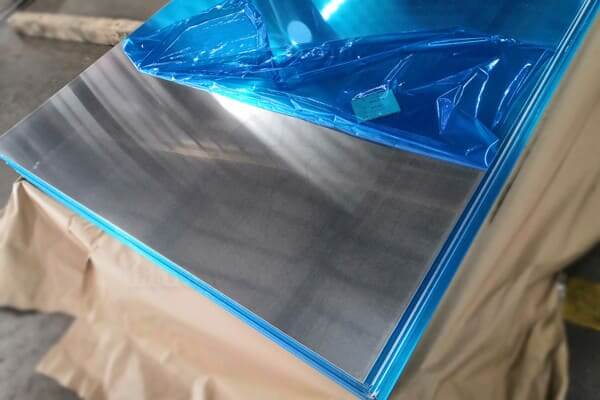

The 5052 aluminum plate also has strong corrosion resistance and has very good formability and durability. Although it is not heat treatable, aluminum 50502 can be strengthened by a work hardening process (5052-H32).

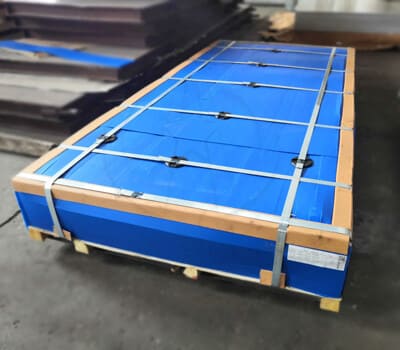

5052-H32 Aluminum Sheet With Sydney Paper

5052 aluminum has excellent corrosion resistance, especially in marine applications. It is suitable for most mechanical and finishing processes, although heavier anode films may appear yellowish.

5052 aluminum plate is a medium hardness alloy. Although it is not recommended to bend sharply, it can be broken and the shape is better. It is an excellent general-purpose alloy often referred to as “anodized premium aluminum” due to its excellent finish.

The 5052 aluminum alloy has a power generation capacity of 193 MPa (28,000 psi) and a closed tensile strength of 228 MPa (33,000 psi), which means it is quite strong compared to some other popular alloys.

| Physical Property | Value |

| Density | 2.68 g/cm³ |

| Melting Point | 605 °C |

| Thermal Expansion | 23.7 x10^-6 /K |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 138 W/m.K |

| Electrical Resistivity | 0.0495 x10^-6 Ω .m |

| Mechanical Property | Value |

| Tensile Strength | 210 – 260 MPa |

| Proof Stress | 130 Min MPa |

| Hardness Brinell | 61 HB |

Generally speaking, the strength of a metal is measured by breaking down the yield strength and tensile strength together. Yield strength considers the strength of a metal shape by measuring the point at which the metal deforms, while tensile strength (or ultimate strength) measures how much the metal stretches before it breaks. The strength of 5052 also depends on temper. A breakdown of the alloy strengths is given in the table below.

Aluminum 5052-h32 cannot be hardened by heat treatment. However, it can be significantly hardened by cold working processes such as cold rolling. Aluminum alloy 5052-h32 is naturally aged and softened at room temperature immediately after cold working.

All aluminum alloy sheet products have stable performance. These properties are achieved through an advanced stabilization heat treatment process.

5052-H32 Aluminum Sheet For Truck Trailer

Because of their light weight, high strength, and aesthetic finish, corrosion-resistant 5052 aluminum sheet and 5052 aluminum sheet are ideal for a variety of marine applications, including shipbuilding, fuel tank assembly, and tubing fabrication. Some other applications that benefit from the corrosion resistance of 5052-h32 aluminum and aluminum sheet include:

5052-H32 Aluminum Sheet For Oil Tank

Generally speaking, the strength of a metal is measured by breaking down the yield strength and tensile strength together. Yield strength considers the strength of a metal shape by measuring the point at which the metal deforms, while tensile strength (or ultimate strength) measures how much the metal stretches before it breaks. The strength of 5052 also depends on temper. A breakdown of the alloy strengths is given in the table below.

| Strength Psi | Elongation % |

|

|||

| Alloy & Temper | Ultimate | Yield Set 0.2% | 1/16” | ½” | Brinell Hardness |

| 5052-0 | 28,000 | 13,000 | 25 | 30 | 47 |

| 5052-H32 | 33,000 | 28,000 | 12 | 18 | 60 |

| 5052-H34 | 38,000 | 31,000 | 10 | 14 | 68 |

| 5052-H36 | 40,000 | 35,000 | 8 | 10 | 73 |

| 5052-H38 | 42,000 | 37,000 | 7 | 8 | 77 |

Along with a few other 5000 series alloys, 5052 is corrosion resistant against seawater and salt spray. Its corrosion resistance means it can be used for large marine structures that are sensitive to failure, like the tanks of natural gas tankers. This is why you see 5052 aluminum sheet on boats in general.

Marine 5052 Aluminum

You’ll frequently see 5052 alloy in architectural facades.

You often see 5052 alloy aluminum sheet in kitchen cabinets, appliances, fans and fan blades, home freezers, clock plates, fencing, and more.

5052 alloy aluminum has made its way into aircraft, bus, and truck manufacturing, road and name signs, fuel lines and tanks, streetlights, and other hallmarks of the transportation industry.

5052 Aluminum Sheet For Building

5052 aluminum sheet is frequently used for general sheet metal work, heat exchangers, flooring panels, rivets and wires, chemical drums and other equipment, pressure vessels, treadplate, containers, and more.

The reason why 3003 aluminum sheet and 5052 aluminum sheet are compared is because they have many similarities in performance and use;

They are both mg-al alloys, but the mg content of 5052 aluminum is higher than that of 3003 alloy aluminum, so the hardness of 5002 alloy aluminum is much higher than 3003 aluminum;

Due to the presence of copper, 3003 aluminum has strong corrosion resistance. This grade also has excellent machinability and solderability.

3003 vs 5052 Aluminum Sheet

5052 aluminum contains no copper, so it is less susceptible to salt water corrosion than copper-containing alloys.

Overall, the ductility and formability of 3003 aluminum sheet are stronger than 5052 aluminum, but the hardness and salt water corrosion resistance of 5052 aluminum are stronger than 3003 aluminum;

Huawei Aluminum is a factory specializing in the production of 5052 aluminum sheets of various sizes and thicknesses, our aluminum sheets are wholesaled to various countries in the world, please contact our sales manager for a price list.

5052 Aluminum Sheet Supplier Near Me

1050 aluminum sheet is a kind of non-heat-treated aluminum plate, which has good plasticity, corrosion resistance, electrical conductivity and thermal conductivity after cold working;

Discover the benefits of 5052 H32 aluminum checkered plates. Lightweight, corrosion-resistant, and anti-slip design ideal for flooring, ramps, vehicles, and marine projects.

Explore the unique properties, manufacturing processes, and wide-ranging applications of 1060 aluminum foil. Learn why this high-purity alloy is essential in packaging, electronics, HVAC, and more.

5052 Aluminum Disc is an Al-Mg alloy renowned for its excellent corrosion resistance, high fatigue strength, and superior workability.

Aluminum Foil For Hair Salon The most common 8011 alloy O Temper, because of excellent strength, flexibility, and heat resistance, Henan Huawei provides you with the best quality 8011-0 aluminum foil for hair salon.

5454 aluminum sheet has strong anti-rust ability and belongs to the 5000 series aluminum-magnesium alloy. 5454 aluminum sheet is also a non-heat treatable alloy and is 20% stronger than 5052 aluminum sheet. It is often used in marine facilities pipelines, aluminum tank car bodies and other fields.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Our required qty: Aluminium Sheet in coil (620mm X 1.20mm) Qty: 200 MT. Can you give me the number of contact urgently. Thanks Matiur Rahman Director of Technical Sales dept.

Bonjour ; Nous sommes une compagnie de spectacle de rue " compagnie carabosse " nous travaillons avec la flamme . nous sommes à la recherche de tôle reflecteur en aluminium pour pouvoir crée un nouvelle objet à base d'un fil métal enflammé liquide éthanol d' une hauteur environ 1 m . Quels produits avez vous à nous proposez ? Cordialement Fabrice

Hello, I am interested in 3*1500*3500 mm 5754 H111 Checkered Aluminium Plate - Diamond Shape Powermaster Ltd. Moscow, Volokolamskoe shosse 1, str. 1, of. 19, Moscow, 125080

Buenos días, Me interesaría saber el costo de Paneles de nido de abeja de aluminio para usar como refuerzo interior de bandejas, estantes , mesadas que realizamos en acero inoxidable AISI 304. De espesor del panel de 10 y 20 mm, con la piel superior e inferior de aluminio espesor 0.8 mm liso o cepillado o solo el núcleo del nido de abeja de aluminio; con tamaño de celda de 10 o 15 mm ( o estándar ) . tamaño de las planchas de 1500 x 3000 mm o la lo que recomiende para el uso que le quiero dar. Desde ya muchas gracias

Proszę o ofertę na blachę aluminiową grubość 20 mm, w gatunku 1060. 8000 kg