AA3003 Aluminum Disc For Pressure Cookers combines food-contact safety, lightweight design, and cost efficiency, making it a preferred choice for modern pressure cooker base construction.

AA3003 Aluminum Disc For Pressure Cookers is a critical functional component widely used in modern pressure cooker design, particularly in the base structure where efficient heat transfer, dimensional stability, and food safety are essential.

As pressure cookers operate under elevated temperature and internal pressure, the materials used in their construction must provide consistent thermal performance, reliable mechanical support, and long-term durability under repeated heating and cooling cycles.

AA3003 aluminum alloy, belonging to the Al–Mn (3xxx) series, is especially well suited for this application due to its excellent formability, moderate strength, and stable corrosion behavior in food-contact environments.

When manufactured into precision aluminum discs, AA3003 enables uniform heat distribution across the cooker base, helping to minimize localized overheating, improve cooking efficiency, and enhance overall user safety.

AA3003 Aluminum Disc For Pressure Cookers

| Element | Typical range (wt%) |

| Aluminium (Al) | Balance |

| Manganese (Mn) | 1.0 – 1.5 |

| Iron (Fe) | ≤ 0.7 |

| Silicon (Si) | ≤ 0.6 |

| Copper (Cu) | ≤ 0.20 |

| Zinc (Zn) | ≤ 0.10 |

| Titanium & others | Trace / controlled |

Why this matters: manganese raises strength above pure aluminium while preserving ductility and formability. Trace impurities are controlled to avoid embrittlement or adverse corrosion behaviour.

These are representative ranges for AA3003 in commonly used tempers; use Mill Test Certificates (MTCs) for procurement values.

AA3003 aluminium circles form a stable, protective oxide (Al₂O₃) that is chemically inert in normal food environments. AA3003 is commonly used in cookware manufacture; however:

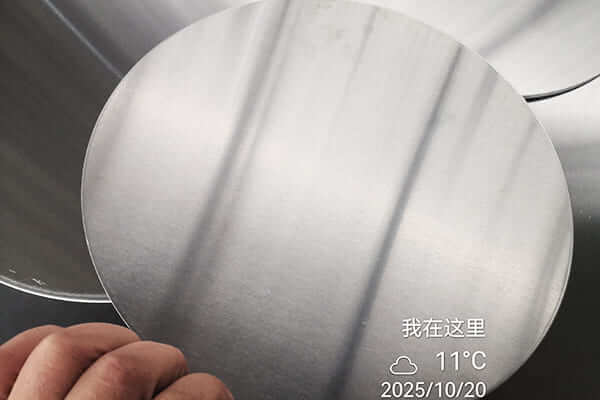

3003 Aluminum Disc Display

Alloy & temper

Thickness

Diameter, concentricity & runout

Flatness / planarity

Surface finish

Edge & burr control

Mechanical & thermal data to verify

3mm thickness 3003 Aluminum Circle

| Feature | Nominal | Standard tolerance (typical) | Tight tolerance (if required) |

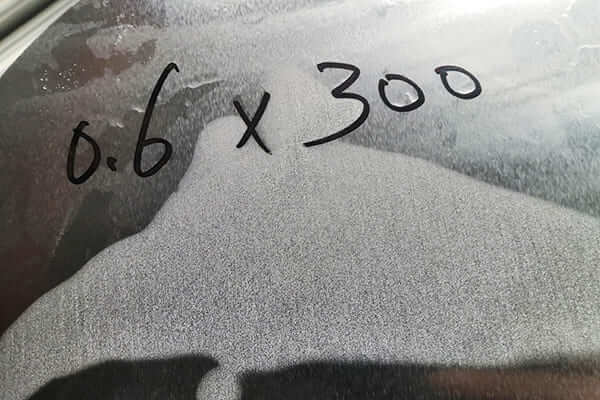

| Thickness | 0.5 – 3.0 mm | ±0.03 mm | ±0.01 mm |

| Diameter | Ø100 – Ø350 mm | ±0.10 mm | ±0.05 mm |

| Concentricity / runout | — | ≤ 0.10 mm | ≤ 0.05 mm |

| Flatness | — | ≤ 0.20 mm | ≤ 0.05–0.10 mm |

| Surface roughness (sealing face) | — | Ra ≤ 3.2 µm | Ra ≤ 0.8–1.6 µm |

| Edge radius | — | ≥ 0.5 mm | ≥ 1.0 mm |

The creation of an AA3003 aluminum disc suitable for a high-performance pressure cooker is a multi-stage, precision-controlled industrial process. It is a journey that transforms a massive, raw aluminum ingot into a perfectly formed, metallurgically optimized component, ready for the demanding deep-drawing process. Each step is critical to ensuring the final product’s quality, safety, and performance.

The homogenized ingot, now called a “slab,” is reheated to a malleable temperature and enters the hot rolling mill.

The hot-rolled coil is then transferred to a cold rolling mill to be reduced to its final, precise thickness for the pressure cooker application (e.g., 4.0mm).

The cold-rolled coil, at its final specified thickness, is fed into a high-speed, high-tonnage mechanical press.

This is the final and most critical thermal treatment that transforms the hard, brittle disc into a workable component for pressure cooker manufacturing.

Grain Size Test

AA3003 aluminum discs play a core role in pressure cookers, and their functions are closely related to the safety and use effect of pressure cookers, mainly reflected in three aspects:

The inner pot and bottom disc made of AA3003 aluminum alloy form the main pressure-bearing structure of the pressure cooker.

The H14/H18 temper discs have sufficient strength and toughness to withstand the instantaneous pressure impact during the working process of the pressure cooker.

The uniform grain structure avoids local stress concentration, and the internal defect control (pore diameter ≤0.2mm) prevents pressure leakage and explosion risks.

The high thermal conductivity of AA3003 aluminum discs enables the pressure cooker to quickly transfer heat from the bottom to the entire inner pot, reducing the heating time by 20-30% compared with stainless steel inner pots.

The heating uniformity error ≤5℃ avoids local overheating and food burning, ensuring the taste of food.

For electric pressure cookers, the excellent thermal conductivity of AA3003 discs can also match the precision temperature control system, improving the intelligence level of the product.

The good forming performance of AA3003 aluminum discs allows them to be processed into various curved inner pot structures, adapting to the design of different capacity and shape pressure cookers.

The corrosion resistance and wear resistance ensure that the disc has a long service life: the service life of household pressure cooker inner pots is 8-10 years, and that of commercial ones is 5-8 years, which is twice that of pure aluminum discs.

At the same time, the lightweight characteristics of AA3003 (density 2.67g/cm³) reduce the overall weight of the pressure cooker, making it easier to handle and use.

Pressure Cookers By Coated Aluminum Discs

| Material | AA3003 Aluminum | AA1100 Aluminum | AA5052 Aluminum | Stainless Steel 304 |

| Alloy family | Al–Mn (3xxx) | Commercial-pure Al | Al–Mg (5xxx) | Austenitic stainless |

| Density (kg/m³) | ~2,700 | ~2,710 | ~2,680 | ~8,000 |

| Thermal conductivity (W/m·K) | ~160 | ~220 | ~138 | ~16 |

| Yield strength (MPa) | ~80–110 | ~35–55 | ~120–160 | ~200–215 |

| Tensile strength (MPa) | ~150–190 | ~90–110 | ~210–260 | ~515 |

| Formability | Excellent | Excellent | Very good | Moderate |

| Corrosion resistance (food use) | Good | Good | Very good | Excellent |

| Weight impact on cooker | Very low | Very low | Very low | High |

| Food-contact suitability* | Good | Good | Good | Excellent |

| Manufacturing cost | Low | Low | Medium | High |

| Typical use in cookers | Heat-spreader discs, base layers | Simple cookware bases | Marine-grade or heavy-duty bases | Structural base, magnetic layer |

AA3003 aluminum discs have become the core material for pressure cookers due to their unique “strength-thermal conductivity-food safety-cost” balance.

Their excellent mechanical properties ensure the pressure-bearing safety of pressure cookers, high thermal conductivity improves heating efficiency and food taste, and strict compliance with food safety standards eliminates potential health risks.

Compared with alternative materials such as pure aluminum, stainless steel, and cast iron, AA3003 aluminum discs have obvious comprehensive advantages, and their market penetration in medium and high-end pressure cookers will continue to increase.

Q1 — Is AA3003 safe for food contact in pressure cookers?

A: AA3003 is widely used in cookware; its natural oxide layer is inert. For regulatory compliance, ensure any coatings or adhesives are food-grade and request supplier conformity documentation. Local rules (FDA, EU) may require specific declarations for coated parts.

Q2 — What thickness should I choose for a 5-litre pressure cooker disc?

A: Typical disc thicknesses for domestic pressure cookers range 1.0–2.0 mm depending on design role (heat spreader vs structural). Use thicker discs for added stiffness or if the disc supports valves or heavy mechanical loads.

Q3 — Can AA3003 discs be welded to stainless steel in multi-layer bases?

A: Direct welding aluminium to stainless is not feasible without specialized techniques. Multi-layer bases are usually bonded (adhesives, diffusion bonding), mechanically clinched, or use transition layers. Laser welding and brazing methods exist but require qualified process controls.

Q4 — How do I specify a disc to avoid warpage in production?

A: Call out temper (H14 commonly), tight thickness control, a post-forming stress relief step if needed, balanced tooling, and flatness tolerance (e.g., ≤ 0.2 mm). Include a prototype run and thermal cycling to validate stability.

Q5 — Is anodizing recommended?

A: Anodizing improves surface hardness and appearance but can slightly reduce thermal contact and must be compatible with any gasket/sealing surfaces. Anodize on non-contact faces or remove/anodize selectively where sealing is not required.

6061 aluminum coil" is an aluminum alloy that is commonly used for applications such as automotive and aerospace components, as well as for construction and industrial products. This article will explore the Properties,Benefits and Applications of 6061 aluminum coil, from its raw material form to the finished product.

Explore the unique properties, manufacturing processes, and wide-ranging applications of 1060 aluminum foil. Learn why this high-purity alloy is essential in packaging, electronics, HVAC, and more.

5754 aluminum sheet has the characteristics of excellent processability, good corrosion resistance, weldability and easy forming. As a wrought alloy, 5754 aluminum sheet can be formed by rolling, extrusion, and forging, but not by casting.

3104 aluminum sheet has suitable elongation, good corrosion resistance and good processability. Therefore, we can smelt it into alloys of different hardness according to different application requirements.

6082 aluminum sheet can be heat treated, strengthened and has good formability, weldability and machinability, also known as structural alloy.

Engineered for efficiency, 24 gauge aluminum sheets combine material economy, excellent surface finish, and recyclability—delivering long-term value for light-duty applications.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip