3104 aluminum sheet has suitable elongation, good corrosion resistance and good processability. Therefore, we can smelt it into alloys of different hardness according to different application requirements.

3104 aluminum is a typical 3000 series aluminum alloy, the main alloy additive is manganese, 3104 aluminum plate belongs to the non-heat treatment strengthened aluminum alloy of AL-Mn alloy series, it is formulated for primary forming into forged products.

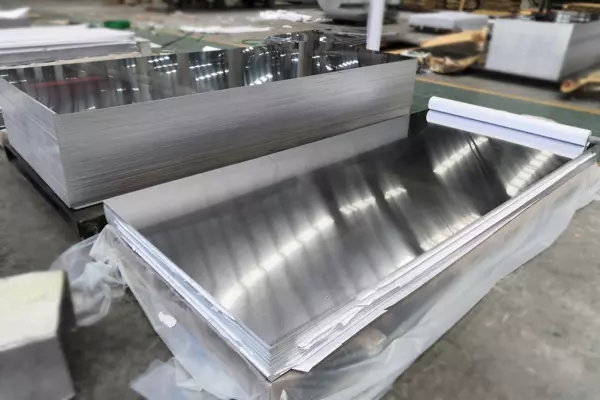

3104 Aluminum Sheet Describtion

It is a deformed aluminum alloy with the advantages of low density, high strength, good corrosion resistance, and easy deep drawing.

| Elements | Si | Fe | Cu | Mn | Mg | Zn | Others | Al |

| Content | 0.6 | 0.8 | 0.05~0.25 | 0.8~1.4 | 0.8~1.3 | 0.25 | 0.05 | Remain |

| Typical alloy | 3104 Aluminum Sheet | |||||||

| Material temper | O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H112 | |||||||

| Thickness (mm) | 0.1-500 | |||||||

| Width (mm) | 100-2650 | |||||||

| Length (mm) | Customize | |||||||

| Typical product | Cans, Color coating with aluminum base material, Lamp head material, Shutter material, etc | |||||||

3104 alloy aluminum plate has good deep-drawing performance and is suitable for thinning, stretching, and lightweighting to reduce material consumption, and has strict requirements for each process of tank material.

3104 aluminum sheet has suitable elongation, good corrosion resistance and good processability. Therefore, we can smelt it into alloys of different hardness according to different application requirements.

3000 series aluminum alloy includes: 3003 Aluminum, 3004 Aluminum Alloy, 3105 Aluminum,etc.

The main state of 3104 aluminum sheet/roll is H111, O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H29, H32, H34, H36, H38, H39, and the maximum tension can be controlled to be greater than or equal to 275MPA , the maximum elongation can be greater than or equal to 20%.

3104-O aluminum is 3104-O aluminum in its annealed condition. It has the lowest strength and highest ductility compared to other variants of 3104 aluminum.

3104-H12 aluminum is 3104 aluminum in the H12 temper. To achieve this tempered state, the metal is strain hardened to about a quarter of the strength between annealed (O) and fully hardened (H18).

3104-H14 aluminum is 3104 aluminum in the H14 temper. To achieve this tempering, the metal is strain hardened to a strength approximately between annealed (O) and fully hardened (H18).

3104-H16 aluminum is 3104 aluminum in the H16 temper. To achieve this tempered state, the metal is strain hardened to approximately 3/4 of its strength between annealing (O) and fully hardening (H18).

3104-H18 aluminum is 3104 aluminum in the H18 temper. This is the strongest temper usually produced only by strain hardening.

3104 Aluminum For Can Lid

3104-H19 aluminum is 3104 aluminum in the H19 temper. To achieve this state, the metal is strain hardened to a strength of at least 10 MPa (or 1.5 ksi) over H18.

3104-H22 aluminum is 3104 aluminum in the H22 state. To achieve this state, the metal is strain hardened and then partially annealed to about a quarter of the strength of annealed (O) and fully hardened (H28).

Data Sources: 3104 Aluminum Tempers

| Mechanical Properties | Metric | English |

| Hardness, Brinell | 78 | 78 |

| Hardness, Knoop | 101 | 101 |

| Hardness, Vickers | 88 | 88 |

| Tensile Strength, Ultimate | 290 MPa | 42100 psi |

| Tensile Strength, Yield | 260 MPa | 37700 psi |

| Elongation at Break | 4.00% | 4.00% |

| Modulus of Elasticity | 69.0 GPa | 10000 ksi |

| Poissons Ratio | 0.34 | 0.34 |

| Shear Modulus | 26.0 GPa | 3770 ksi |

| Shear Strength | 175 MPa | 25400 psi |

3104 is the Aluminum Association (AA) designation for this material.

In European standards it will be designated as EN AW-3104. AlMn1Mg1Cu is the EN chemical name. In addition, the UNS number is A93104.

Excellent processing ductility. 3104 aluminum sheet can be milled, boring and planed at the highest speeds of most machine tools. It can also greatly reduce the thickness and stretching amount, and has good formability and excellent deep drawing effect.

Best corrosion resistance. 3104 aluminum alloy is very resistant to corrosion from gasoline, neutral inorganic salt solutions, organic acids, food, dilute acids or industrial environments.

Excellent anodization. 3104 aluminum plate is a typical color coated substrate, the surface of which has been anodized or coated, showing excellent results.

3104-h19 aluminum sheet has suitable strength, excellent deep impact, formability and ductility, and is most commonly used in beverage and beer cans.

3104-H19 Aluminum Sheet For Cans

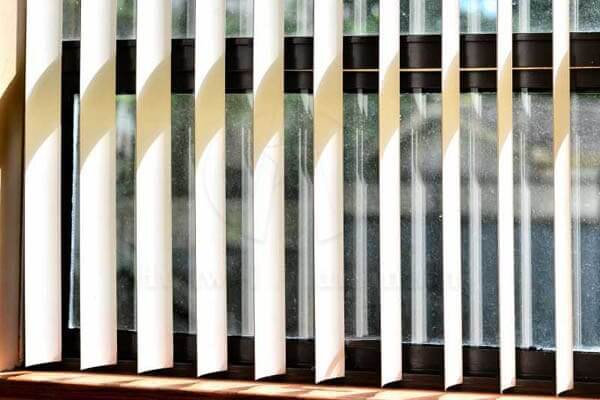

3104 aluminum sheet can also be used for aluminum lamp head materials, aluminum alloy shutter materials, radiators, liquid crystal backplanes, color-coated aluminum substrates, roof tiles, can lids, cake pans, aluminum bottle caps, etc.

3104 Aluminum Sheet For Shutters

3104 board is generally considered to be a roof with a designed service life of more than 50 years, and is widely used in airport terminals, aircraft maintenance, transportation hubs, Daxing, convention and exhibition centers, stadiums, exhibition halls, public service buildings, Daxing shopping centers, etc.

Huawei aluminum products meet export standards. Can be covered with plastic film and kraft paper according to customer requirements. What’s more, wooden boxes or wooden pallets are used to protect the product from damage during shipping.

3104 Aluminum Sheet Packaging

Generally speaking, a pack of 2 tons, 18-22 tons in a 1×20’ container, 20-24 tons in a 1×40’ container.

Aluminum circle for road sign refers to the aluminum circle used in the production of road signs. Because aluminum circles have strong corrosion resistance and weather resistance, aluminum circles are very suitable for the production of road signs.

8006 aluminum foil is a specific alloy known for its excellent barrier properties, making it ideal for packaging applications. It provides effective protection against moisture, light, and oxygen, helping to preserve the freshness and quality of food products.

Common aluminium disc circle for lamps are 1050-O, 1060-O, 1100-O, etc., because the lampshade is obtained by stamping aluminum discs, and the O-state aluminum discs have better ductility and are more suitable for stamping treatment;

3000 series aluminum alloy is an AL-MG alloy whose main components are aluminum, manganese and a small amount of other elements. It has excellent properties such as good corrosion resistance, processability and weldability.

0.75 aluminum sheet refers to an aluminum sheet with a thickness of 0.75 inches, also known as 0.75" aluminum sheet;

Learn how non-stick aluminum foil works, its high-performance coatings, heat resistance, and benefits in food safety and sustainability. A must-read guide for chefs and manufacturers.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

2000x3000mm aluminum sheet Price and transport

Our required qty: Aluminium Sheet in coil (620mm X 1.20mm) Qty: 200 MT. Can you give me the number of contact urgently. Thanks Matiur Rahman Director of Technical Sales dept.

Bonjour ; Nous sommes une compagnie de spectacle de rue " compagnie carabosse " nous travaillons avec la flamme . nous sommes à la recherche de tôle reflecteur en aluminium pour pouvoir crée un nouvelle objet à base d'un fil métal enflammé liquide éthanol d' une hauteur environ 1 m . Quels produits avez vous à nous proposez ? Cordialement Fabrice

Hello, I am interested in 3*1500*3500 mm 5754 H111 Checkered Aluminium Plate - Diamond Shape Powermaster Ltd. Moscow, Volokolamskoe shosse 1, str. 1, of. 19, Moscow, 125080

Buenos días, Me interesaría saber el costo de Paneles de nido de abeja de aluminio para usar como refuerzo interior de bandejas, estantes , mesadas que realizamos en acero inoxidable AISI 304. De espesor del panel de 10 y 20 mm, con la piel superior e inferior de aluminio espesor 0.8 mm liso o cepillado o solo el núcleo del nido de abeja de aluminio; con tamaño de celda de 10 o 15 mm ( o estándar ) . tamaño de las planchas de 1500 x 3000 mm o la lo que recomiende para el uso que le quiero dar. Desde ya muchas gracias