3105 Aluminum Sheet is adding some other elements on the basis of pure aluminum, such as cu, mg, si, mn, etc., the purpose is to improve the strength of aluminum alloy

3105 Aluminum Sheet is adding some other elements on the basis of pure aluminum, such as cu, mg, si, mn, etc., the purpose is to improve the strength of aluminum alloy, the final aluminum content is 98%, the chemical composition of 3105 aluminum alloy is as follows.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: Each |

Others: Total |

Al: Min. |

| 3105 | 0.60 | 0.70 | 0.30 | 0.3~0.8 | 0.2~0.8 | 0.20 | 0.40 | 0.10 | 0.05 | 0.15 | remainder |

Aluminum alloy 3105 is essentially a 98% aluminum alloy with minor elements added to increase strength compared to alloys 1100 and 3003.

It cannot be hardened by heat treatment and has good corrosion resistance, formability and weldability.

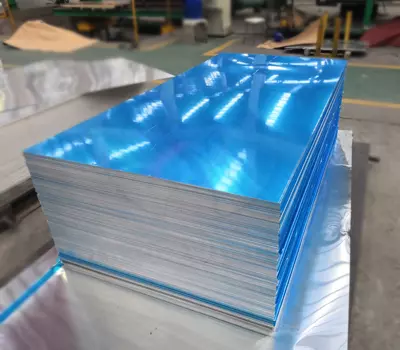

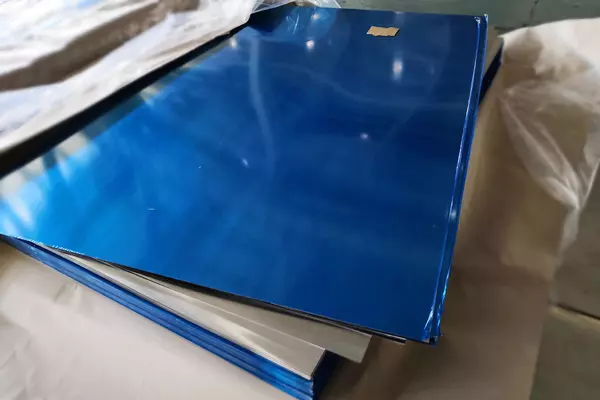

3105 Aluminum Sheet With Blue Film

0.3% copper is added to the 3105 aluminum sheet, and the conductivity is 41%.

The content and processing technology of 3105 aluminum plate, light weight and semi-smooth surface.

Typical applications include general sheet metal fabrication, residential siding, mobile homes, and signage that require higher strength than 1000 series aluminum alloys.

3105 aluminum is formulated for primary forming into forged products. 3105 is the Aluminum Association (AA) designation for this material.

In European standards it will be designated as EN AW-3105. N31 is the British Standard (BS) designation. A93105 is the UNS number. Additionally, the EN chemical name is AlMn0,5Mg0,5.

It originally received the standard name in 1960.

| Property | Value |

| Density | 2.71 g/cm3 |

| Melting Point | 643 – 657°C |

| Thermal Expansion | 23.1 ×10−6 /K |

| Modulus of Elasticity | 69.5 GPa |

| Thermal Conductivity | 160 W/m.K |

| Electrical Resistivity | 0.034 ×10−6Ω.m |

3105 aluminum alloy has good corrosion resistance, good plasticity and machinability, and good gas welding and arc welding performance. The strength of 3105 aluminum is slightly higher than that of 3003 aluminum, and other properties are similar to 3003 aluminum alloy. 3105 aluminum has good anti-rust performance, good electrical conductivity, and the electrical conductivity can reach 41%. The 3105 aluminum plate has high plasticity in the annealed state, but still has good plasticity in the semi-cold hardened state. Low plasticity, good corrosion resistance, good weldability, and poor cutting performance in the quenched state.

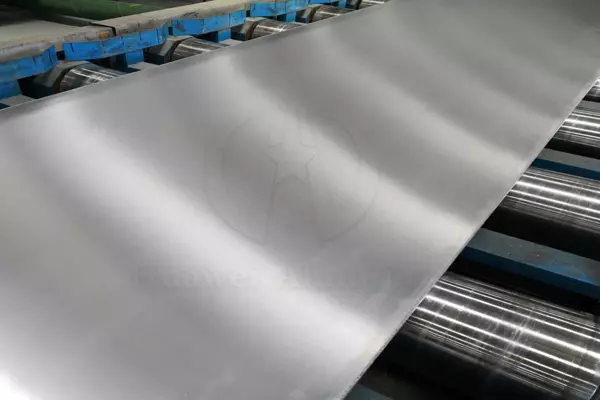

Rolling Aluminum Sheet

There are a couple differences between 3003 H14 and 3105 H24. One of them is the Brinell Hardness; 3003 H14 has 42 BHN and 3105 H24 has 47 BHN. Another difference is the Fatigue Strength; 3003 H14 has only 60 MPa, whereas 3105 H24 has 74 MPa. In the alloy composition, 3003 H14 contains more Magnesium than 3105 H24. But 3105 H24 contains a little bit of Titanium, Chromium and Copper that 3003 H14 does not have.

H111、H12、H14、H16、H18、H19、H22、H24、H25、H26、H28、HO,etc.

No matter how tempered the 3105 aluminum sheet is, the forming characteristics of all conventional processes are very good. The 3105 aluminum plate has no reaction to heat treatment except for annealing during the cold working process. The cold working properties are very good, even in the hard cold working state. In view of all the above characteristics, 3105 aluminum sheet is widely used in many fields.

| Elements | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Content | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.2 | 0.4 | 0.1 | 0.15 | Remain | ||

| Alloy Temper |

Specified thickness |

Tensile strength |

Yield strength |

Elongation | ||||||||

| (inches) | (KSI) | (KSI) | (%) | |||||||||

| 3105 (annealed) |

0.013-0.019 | 96-145 | Min34 | 16 | ||||||||

| 0.020—0.031 | 18 | |||||||||||

| 0.032-0.080 | 20 | |||||||||||

| 3105-H12 | 0.017-0.019 | 131-179 | Min103 | 1 | ||||||||

| 0.020-0.031 | 1 | |||||||||||

| 0.032-0.050 | 2 | |||||||||||

| 0.051-0.080 | 3 | |||||||||||

| 3105-H14 | 0.013-0.019 | 152-200 | Min124 | 1 | ||||||||

| 0.020-0.031 | 1 | |||||||||||

| 0.032-0.050 | 2 | |||||||||||

| 0.051-0.080 | 2 | |||||||||||

| 3105-H16 | 0.013-0.031 | 172-221 | Min145 | 1 | ||||||||

| 0.032-0.050 | 2 | |||||||||||

| 0.051-0.080 | 2 | |||||||||||

| 3105-H18 | 0.013-0.031 | Min193 | Min165 | 1 | ||||||||

| 0.032-0.050 | 1 | |||||||||||

| 0.051-0.080 | 2 | |||||||||||

| 3105-H25 | 0.013-0.019 | Min15 | Min131 | 2 | ||||||||

| 0.020-0.031 | 3 | |||||||||||

| 0.032-0.050 | 4 | |||||||||||

| 0.051-0.080 | 6 | |||||||||||

For the bottle mouth industry of the wine industry, the excellent processing performance of 3105 aluminum alloy and the excellent deep drawing performance of 3105 aluminum are required to meet the design requirements of different wine bottle mouths. Considering the internal and external environment of the bottle cap, the good corrosion resistance of 3105 aluminum alloy is more prominent.

Bottle Cap 3105 Aluminum

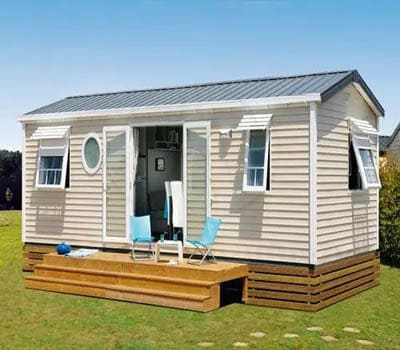

3105 aluminum alloy is used in mobile homes. Its good corrosion resistance is essential. It is easy to form a dense aluminum oxide protective film in the atmosphere. Therefore, 3105 aluminum alloy is no problem to build mobile houses in corrosive environments such as islands. And the chemical properties of 3105 aluminum are particularly stable. If the film surface is scratched and damaged, new films can be produced very quickly. This provides excellent isolation and protection.

3105 Aluminum Sheet For Building

Anodized 3105 aluminum alloy sheet, the surface can be sprayed with rich colors, and the workability is good, making the produced lamps, rain gear and other products full of design sense, long-term non-discoloration, non-corrosion, non-oxidation, non-rusting, and strong weather resistance.

3105 Aluminum Sheet For Car

In addition, 3105 aluminum plate is also often used in humid environments such as air conditioners, refrigerators, and car bottoms, as well as stair treads, ship platforms, non-slip floors, refrigerators, etc.

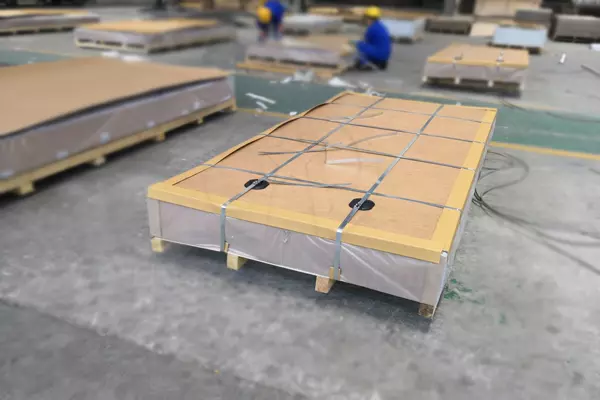

Huawei 3105 aluminum sheet. Compliant with export standards. It can be covered with plastic film and kraft paper according to customer needs. What’s more, use wooden boxes or wooden pallets to protect the products from damage during transportation. There are two kinds of packaging, one is eye to wall and the other is eye to sky. For convenience, customers can choose any of them. Generally speaking, a pack of 2 tons, 1×20′ container is loaded with 18-22 tons, and 1×40′ container is loaded with 20-24 tons.

3105 Aluminum Sheet With Wooden Pallet

As a China 3105 aluminum sheet manufacturer and supplier, we also produce aluminum cut coils, aluminum strips, coated aluminum coils, aluminum sheets, anodized aluminum sheets, embossed aluminum sheets, etc. in huawei. For more details, please continue to browse our website or feel free to contact us directly.

Pharmaceutical foil, also known as medical-grade foil or blister foil, 8011,8021,8079 aluminum foil common used for Pharmaceutical packaging foil.

Reflective aluminum sheet is a metal sheet with high reflectivity and is widely used in optics, electronics, construction and other fields. This article will introduce the principles, characteristics and applications of Reflective aluminum sheets.

5052 aluminum sheet is part of the 5000 series of aluminum. The grades in this series are alloyed with magnesium (2.5%) and have medium to high strength properties.

Common aluminium disc circle for lamps are 1050-O, 1060-O, 1100-O, etc., because the lampshade is obtained by stamping aluminum discs, and the O-state aluminum discs have better ductility and are more suitable for stamping treatment;

5000 series aluminum alloy is an Al-Mg alloy series with high strength and excellent corrosion resistance. It is commonly used in the manufacturing of marine, oil tanks, ships, automobile, building materials and other fields.

3A21 aluminum plate is an Al-Mn series aluminum alloy, which belongs to the weldable LF21 aluminum alloy and is known for its excellent anti-rust properties.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sirs, I'm looking for a provider of aluminum 7075-T651 in 1.0 or 1.5 mm thickness. We need about 180 plates of 200 mm x 200 mm. Are you able to provide a quote and delivery time for this? Thank you so much in advance. Kind regards, Francisco Silva

Hello, I hope this message meets you well. I have perused your website and I want a detailed price quote for your product; upon your response to this message I will forward more details concerning this order/project to you. I look forward to doing business with you. Warm thanks. Best regards, Ahmet Emir Purchase Manager SER MEKATRONIK SANAYI VE TICARET LTD.STI. Turkgucu O.S.B. Mahallesi 216.Sokak NO:5/1 Corlu / Tekirdag / Turkey Email: [email protected]

I need a quotation for 3000 series aluminum sheets/coils (3104 H19) for tuna can production, food-grade finish, delivery to Mazatlán, Mexico.

I am planning a business trip to China and I am very interested in your aluminium 8011 products for food container production. I would like to visit your factory during my stay in china: See your production lines (foil rolling, annealing, slitting, packing). Discuss specifications (8011-O temper, thickness 0.05–0.08 mm, jumbo roll). Review your quality certificates and export experience. Could you please let me know: Your available dates for a visit The location of your factory If you can provide an invitation letter for my business visa (M visa). Thank you for your kind support. Looking forward to your reply. Best regard: LOUNIS MUSTAPHA company name:TOP BARQUETTE SELECT [email protected] what's up:213 770 91 69 43

Merhaba ; Burak ÜNAL ben. Antalya ' da Ambalaj ve Temizlik ürünleri tedarik eden bir firmanın yetkilisiyim. Ayrıca P.E Streç aktarım işi yapmaktayım. Makinalarımızı 9 ve 10 micron alüminyum folyo aktarımına uyacak şekilde revize edeceğiz. Sizden istediğim, 9 veya 10 micron olacak şekilde 35 cm ve 45 cm jumbo folyolar için fiyat, termin ve şu bilgileri istiyorum ; 35 cm jumbo folyonun ortalama ağırlığı. 45 cm jumbo folyonun ortalama ağırlığı. Deneme olacağı için bu 2 ölçüde minimum sipariş tonajımız ne kadar olması gereklidir. İyi çalışmalar.