5083 Aluminum Sheet is known for its superior performance in extreme environments. 5083 Aluminum is highly resistant to corrosion from seawater and industrial chemical environments.

5083 Aluminum Sheet is known for its superior performance in extreme environments. 5083 Aluminum is highly resistant to corrosion from seawater and industrial chemical environments.

Alloy aluminum 5083 also maintains excellent strength after welding. It has the highest strength of a non-heat treatable alloy, but is not recommended for use above 65°C.

5083 Aluminum Sheet Display(Al-Mg-Mn)

5083/5086 aluminum sheet has higher strength than 5052 aluminum sheet and has excellent corrosion resistance, especially salt water corrosion resistance. It is easy to form, stamp and weld.

5083 aluminum sheet belongs to Al-Mg-Si series aluminum alloy. Its main components are magnesium and silicon, in addition to aluminum. More than 4.0% magnesium makes the 5083 aluminum plate have excellent resistance to correction and easy welding. By adding copper, the 5083 aluminum plate has a conductivity of 28%.

5083 Aluminium Sheet (DC)

5083 aluminum sheet has good forming properties whether it is hot worked or cold worked. But hardening is done only by cold working. In addition, 5083 aluminum plate does have good strength, but it is not heat treatable.

| Max (%) | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: Each |

Others: Total |

Al: Min. |

| 0.40 | 0.40 | 0.10 | 0.4~1.0 | 4.0~4.9 | 0.05~0.25 | 0.25 | 0.15 | 0.05 | 0.15 | remainder |

| OLD | WNr | UNS | ISO | USA (AA) | GERMANY (DIN) | British |

| AG4,5MC | 3.3547 | A95083 | AlMg4,5Mn0,7 | 5083 | AlMg4,5Mn | EN AW-5083. N8 |

The Density of 5083 Aluminum Plate is 2650 kg/m³ (0.096 lb/in3),Melting point is 518°F (270°C). Modulus elasticity of 72 GPA and thermal conductivity of 121 W/mK.

| Property | Metric | Imperial |

|---|---|---|

| Hardness, Brinell | 85 | 85 |

| Hardness, Knoop | 109 | 109 |

| Hardness, Rockwell A | 36.5 | 36.5 |

| Hardness, Rockwell B | 53 | 53 |

| Hardness, Vickers | 96 | 96 |

| Ultimate Tensile Strength | 317 MPa | 46000 psi |

| Tensile Yield Strength | 228 MPa | 33000 psi |

| Elongation at Break | 16% | 16% |

| Modulus of Elasticity | 70.3 GPa | 10200 ksi |

| Compressive Modulus | 71.7 GPa | 10400 ksi |

| Poissonn’s Ratio | 0.33 | 0.33 |

| Fatigue Strength | 159 MPa | 23000 psi |

| Fracture Toughness | 43 MPa-m½ | 39.1 ksi-in½ |

| Machinability | 30% | 30% |

| Shear Modulus | 26.4 GPa | 3830 ksi |

| Shear Strength | 190 MPa | 27600 psi |

5083-H116/H321 aluminium plates are often used for the underwater part of the ships because of its excellent corrosion resistance.

5083-H116 Aluminum Sheet

5083-H116/H321 aluminum sheets have better corrosion resistance than temper H111 and H112 more suitable for marine underwater environments. Although 5083 H116 and H321 aluminum sheets have slightly different temperatures during production, their corrosion resistance is significantly better than other tempers.

5083 Aluminum Sheet For Shipbuilding

There are many annealing tempers for 5083 aluminum alloy, and the properties of different tempers are also different.

Tempering is achieved by fully annealing the steel sheet and then rolling to the desired tempering temperature rather than heat treating.

5083 Alloy H321/H116 Aluminum Sheets are commonly used in ship/boat building.

O, H32, H38 can be used in automotive and other industries.

Automotive 5083-h32 Aluminum Plate

The performance of H116 and H321 degrades when the thickness exceeds 40mm. The tensile strength is 285 MPa·min, and the yield strength is 200 MPa·min.

The elongation specified in H116 and H321 varies slightly depending on the specification. The measurement distance is also different. See ASTM B928M for details.

| Alloy & Temper |

Spec | Tensile Strength (MPa) | Yield Strength 0.2% Proof (MPa) | Elongation (% in 50mm) minimum for sheet or plate thicknesses shown |

||

| All gauges (Note 2) | 5.0- 12.5mm |

6.31- 80.0mm |

||||

| 5083-O | B209M | 270-345 | 115-200 | – | – | 16 |

| 5083-H32 | B209M | 305-385 | 215 min | – | 12 | – |

| 5083-H116 | B928M | 305 min(1) | 215 min(1) | 10 | – | – |

| 5083-H321 | B928M | 305-385(1) | 215 min(1) | 10 – 12 | – | – |

https://en.wikipedia.org/wiki/5083_aluminium_alloy

5083 marine aluminum plate is a typical Al-Mg-Si alloy with high corrosion resistance and rust resistance. The underwater part of the hull, especially in seawater, must be able to resist corrosion from seawater. The most commonly used are 5083-H116 and 5083-H321 aluminum sheets.

Typical Applications Of 5083 Aluminum Sheet

5083 aluminum plate is mainly used for deck, engine base, ship side and bottom outer plate.

5083-H116 aluminum sheet is also used in transportation fields, such as automobiles, aircraft fuel tanks, etc.

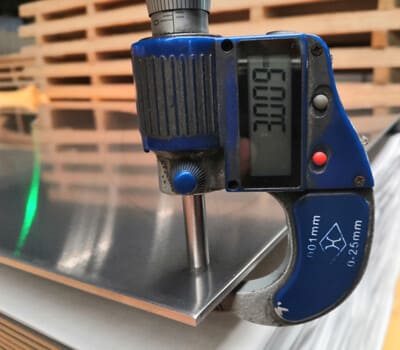

Huawei Aluminum provides various sizes and thicknesses of 5083 aluminum sheets (including ultra-wide sheets). Our 5083 aluminum sheets will undergo various tests before leaving the factory to ensure the quality of our customers’ products.

Huawei 5083 Aluminum Sheet

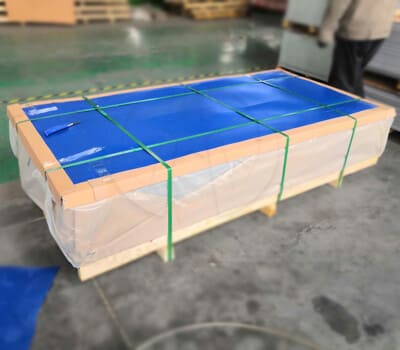

Huawei 5083 Aluminum Sheet Packaging

During the production process, a small amount of beryllium is added to the 5083 aluminum sheet to reduce the cracking tendency of the ingot and improve the surface quality of the rolled sheet.

5083 marine aluminum plate is certified by DNV and CSS.

5083 aluminum plate is free of oil spots, scratches, rolling marks, burrs and cut edges.

With strong production capacity, it can accept orders of 8-5000 tons and deliver within 7-35 days. Based on our strong supply ability, we can also offer you the best price of aluminum sheet 5083.

3105 Aluminum Sheet is adding some other elements on the basis of pure aluminum, such as cu, mg, si, mn, etc., the purpose is to improve the strength of aluminum alloy

5000 Series Rolled Mirror Aluminum Plate is a high-quality aluminum alloy product characterized by its exceptional surface reflectivity (≥85%) and corrosion resistance. Manufactured through advanced cold rolling and polishing processes, it achieves a mirror-like finish while retaining the strength and formability of the 5000 series alloys.

Aluminum strip for transformer means that aluminum strip is used as conductive material in the high and low voltage windings of dry-type transformers and oil-immersed transformers.

High-adhesion, corrosion-resistant 8011 gold hydrophilic aluminum foil for sealing, lamination, and HVAC applications.

Anodized aluminum sheet is an aluminum sheet placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as an anode, and electrolysis is performed under specific conditions and the action of external current.

Flexible packaging aluminum foil is a thin foil made of aluminum that is commonly used in food packaging and pharmaceutical packaging. Unlike hard aluminum foil, flexible packaging aluminum foil is soft and can adapt to various shapes of containers, so it is widely used for packaging food and medicine.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

2000x3000mm aluminum sheet Price and transport

Our required qty: Aluminium Sheet in coil (620mm X 1.20mm) Qty: 200 MT. Can you give me the number of contact urgently. Thanks Matiur Rahman Director of Technical Sales dept.

Bonjour ; Nous sommes une compagnie de spectacle de rue " compagnie carabosse " nous travaillons avec la flamme . nous sommes à la recherche de tôle reflecteur en aluminium pour pouvoir crée un nouvelle objet à base d'un fil métal enflammé liquide éthanol d' une hauteur environ 1 m . Quels produits avez vous à nous proposez ? Cordialement Fabrice

Hello, I am interested in 3*1500*3500 mm 5754 H111 Checkered Aluminium Plate - Diamond Shape Powermaster Ltd. Moscow, Volokolamskoe shosse 1, str. 1, of. 19, Moscow, 125080

Buenos días, Me interesaría saber el costo de Paneles de nido de abeja de aluminio para usar como refuerzo interior de bandejas, estantes , mesadas que realizamos en acero inoxidable AISI 304. De espesor del panel de 10 y 20 mm, con la piel superior e inferior de aluminio espesor 0.8 mm liso o cepillado o solo el núcleo del nido de abeja de aluminio; con tamaño de celda de 10 o 15 mm ( o estándar ) . tamaño de las planchas de 1500 x 3000 mm o la lo que recomiende para el uso que le quiero dar. Desde ya muchas gracias