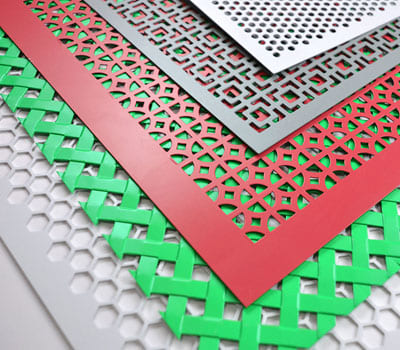

Powder coated aluminum sheet refers to the aluminum sheet processed by powder spraying process;

Powder coated aluminum sheet refers to the aluminum sheet processed by powder spraying process;

The purpose is to change the surface of the aluminum sheet, so that the surface has beautiful colors and patterns, and at the same time enhance the weather resistance of the aluminum sheet;

powder coated aluminum sheet

Powder coating is to spray a powder coating on the surface of aluminum alloy substrate through electrostatic action. The adhesion, weather resistance, peeling resistance, strong UV resistance and dense coating of the coating are incomparable to the surface treatment of general aluminum profiles. The spraying effect is superior to the spraying process in terms of mechanical strength and aging resistance, and the cost is also lower. Under spray paint with the same effect.

PE: polyurethane, polyurethane resin, epoxy resin, hydroxyl polyester resin and epoxy polyester resin

PVDF: Fluorocarbon coating

Coating thickness: It can be divided into single coating (4μm-20 μm); double coating (25μm-28 μm); 3 coating (35μm-38μm).

At present, the current situation of Our country powder coated aluminium sheet is that the production capacity of ordinary products is excessive, and the production capacity of high-tech, high-precision and high-quality products is insufficient, which also leads to a large number of imports.

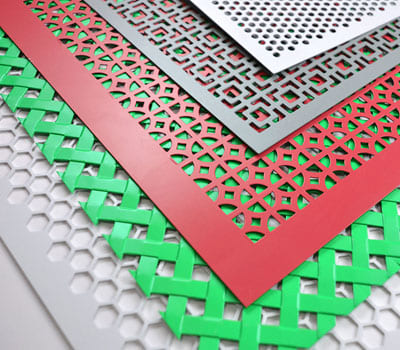

punched powder coated aluminum sheet

Features of powder spraying: manual spraying equipment, automatic hanging type, simple construction, coating thickness of more than 30 microns, good impact resistance, abrasion resistance, corrosion resistance, weather resistance, etc., the coating price is cheaper than fluorocarbon .

The biggest disadvantage of powder spraying is: fear of ultraviolet radiation from the sun, long-term exposure will cause natural fading, and the color difference between the sunny side and the non-sunny side of the door and window profiles will be obvious after a few years, usually within 2-5 years.

Loading → pretreatment (chromizing) → spraying → curing → dropping

Purpose of chromizing: to form a fine and stable chromizing film on the surface of aluminum. This film layer has a certain degree of wear resistance, corrosion resistance and good adsorption capacity, so that the paint can improve its adhesion when it is painted.

powder coating process

Curing: Powder spraying is baked and leveled at high temperature and cured to form a final coating with different effects; in powder spraying, the baking and curing temperature and time of powder coating play a decisive role in the curing performance of the coating film. Therefore, it is necessary to classify the objects to be sprayed reasonably through multiple tests to determine the number and arrangement of the pendants, as well as the corresponding baking and curing temperature and time, in order to ensure the quality of the coated product.

| Huawei Coat’s Aluminum Powder coated sheet Data Sheet | |||

| Item | Standard | Test Result | Remark |

| Coating thickness | ≥40 um | ≥40 um | |

| Gloss | +/-5 | 30 | |

| Pencil Hardness | ≥HB | 2H | |

| Impact resistance | 50KG.cm no peel off | 50KG.cm no peel off | |

| Wear Resistance | ≥5L/um | 16L/um | |

| Outlook | No flow marks, bubbles, inclusions, and other surface defects | No flow marks, bubbles, inclusions, and other surface defects | |

| Noise Insulation Factor | Noise insulation RW=40dB | ||

| Adhesive Force | Follow the standard | Kriging Grade 0 | |

| Chemical Resistance | Follow the standard | 15 minutes drip no bubbles, no change in appearance | Resistant to hydrochloric acid |

| E=0.48NBS | Resistance to nitric acid | ||

| No bubbles, no film loss | Detergent-resistant | ||

Powder coating of aluminum veneer is to use powder spraying equipment (electrostatic spraying machine) to spray powder coating on the surface of aluminum sheet, and there are many types of powder coating process. Under the action of static electricity, the powder will be evenly adsorbed on the surface of the workpiece to form a powder coating; the powder coating is then baked and leveled at a high temperature to become a final coating with different effects (different types of powder coating effects). The spraying effect of powder spraying is better than that of spraying paint in terms of mechanical strength, adhesion, corrosion resistance, aging resistance, etc. Compared with spraying paint with the same effect, the cost is lower.

powder coated aluminum sheet

Advantages of powder coating compared with traditional painting process:

Powder coating of aluminum sheets is a common surface coating technique that involves spraying fine powder paint onto the surface of aluminum sheets through a spray gun, and then forming a solid coating during drying and curing. This technique has wide applications in many fields, here are some examples:

Construction and building materials: Powder coated aluminum sheets are commonly used in construction for the coating of exterior walls, window frames, doors, railings and other metal components. This coating provides weather and corrosion resistance, making the building structure more durable.

brown powder coated aluminum sheet

Household items: Household items such as furniture, lamps, door handles, etc. are also often used powder coating aluminum sheet technology to endow the products with rich colors and decorative effects.

Automobiles and vehicles: Powder coated aluminum sheets are used for surface coating of body, wheels, frame and other components in automobile manufacturing. This coating provides scratch resistance, corrosion resistance and improved appearance.

Electronic products: Powder coated aluminum sheets are also used on the casing and exterior parts of electronic products, such as computer casings, audio casings, etc., which can protect the equipment and give it a beautiful appearance.

Outdoor facilities: Seats and sunshade structures of outdoor facilities such as parks and squares can also use powder coated aluminum sheet technology to increase the durability and visual appeal of the product.

Industrial equipment: Mechanical equipment, pipelines, storage tanks and other metal components in the industrial field can also be surface coated by powder spraying aluminum sheet technology to prolong service life and improve corrosion resistance.

Sports facilities: sports venues, fitness equipment, etc. can also use powder coated aluminum sheets for surface decoration and protection.

In general, powder coated aluminum sheets are widely used, mainly because they can provide metal surfaces with multiple functions such as durability, beauty, and corrosion resistance, and are suitable for various industries and fields.

Our commitment to quality, variety, and customization ensures that you'll find the perfect insulation aluminum coil for your project.

8021 aluminum foil has the characteristics of cleanliness and hygiene, and can be made into an integrated packaging material with many other packaging materials. In addition, the surface printing effect of 8021 aluminum foil is better than other materials. Therefore, 8021 aluminum foil alloy can also be used in the field of food packaging.

The 3000 series rolled mirror aluminum plate is a premium aluminum product known for its exceptional reflectivity, durability, and versatility. It is widely used in industries where aesthetics and performance are critical.

Perforated aluminum sheets are made by aluminum sheets that have been machined with round holes (or other designs). The holes can be in line or staggered to increase the number of openings.

7075 aluminum sheet is the strongest heat-treatable alloy, introduced by Alcoa in 1943, and can be heat-treated to achieve strength levels comparable to many steel alloys.

5454 aluminum sheet has strong anti-rust ability and belongs to the 5000 series aluminum-magnesium alloy. 5454 aluminum sheet is also a non-heat treatable alloy and is 20% stronger than 5052 aluminum sheet. It is often used in marine facilities pipelines, aluminum tank car bodies and other fields.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Hello, I am interested in 3*1500*3500 mm 5754 H111 Checkered Aluminium Plate - Diamond Shape Powermaster Ltd. Moscow, Volokolamskoe shosse 1, str. 1, of. 19, Moscow, 125080

Buenos días, Me interesaría saber el costo de Paneles de nido de abeja de aluminio para usar como refuerzo interior de bandejas, estantes , mesadas que realizamos en acero inoxidable AISI 304. De espesor del panel de 10 y 20 mm, con la piel superior e inferior de aluminio espesor 0.8 mm liso o cepillado o solo el núcleo del nido de abeja de aluminio; con tamaño de celda de 10 o 15 mm ( o estándar ) . tamaño de las planchas de 1500 x 3000 mm o la lo que recomiende para el uso que le quiero dar. Desde ya muchas gracias

Proszę o ofertę na blachę aluminiową grubość 20 mm, w gatunku 1060. 8000 kg

Dear Sirs, I'm looking for a provider of aluminum 7075-T651 in 1.0 or 1.5 mm thickness. We need about 180 plates of 200 mm x 200 mm. Are you able to provide a quote and delivery time for this? Thank you so much in advance. Kind regards, Francisco Silva

Hello, I hope this message meets you well. I have perused your website and I want a detailed price quote for your product; upon your response to this message I will forward more details concerning this order/project to you. I look forward to doing business with you. Warm thanks. Best regards, Ahmet Emir Purchase Manager SER MEKATRONIK SANAYI VE TICARET LTD.STI. Turkgucu O.S.B. Mahallesi 216.Sokak NO:5/1 Corlu / Tekirdag / Turkey Email: [email protected]