040 Aluminum Sheet is a type of aluminum sheet that has a thickness of 0.04 inches, which is equivalent to 1.016 millimeters. It is a thin and lightweight material

040 Aluminum Sheet is a type of aluminum sheet that has a thickness of 0.04 inches, which is equivalent to 1.016 millimeters. It is a thin and lightweight material that is commonly used in various applications, including automotive, aerospace, construction, and industrial applications, as well as for general fabrication and DIY projects.

Thickness Of 040 Aluminum Sheet

040″ Aluminium Sheet is made from high-quality aluminum alloy, which provides it with excellent strength, durability, and corrosion resistance properties. It can be easily formed, welded, and machined, making it a versatile material for a wide range of applications. The sheet is available in various sizes, grades, and finishes, and can be customized according to specific requirements.

Lightweight

One of the key advantages of 040 Aluminum Sheet is its lightweight nature. It is one-third the weight of steel, which makes it easy to transport, handle, and install. Its lightweight nature makes it an ideal choice for applications where weight is a critical factor.

Corrosion-resistant

040 Aluminium Sheet is highly resistant to corrosion and rust, making it suitable for use in harsh environments. It can withstand exposure to seawater, industrial chemicals, and other corrosive substances, making it a popular choice for marine, chemical, and manufacturing industries.

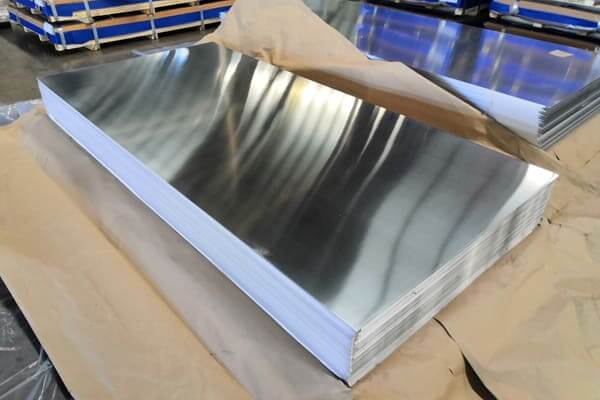

040 Aluminum Sheet Overview

Durable

The material is long-lasting and can withstand wear and tear, making it suitable for use in high-traffic areas. It is also resistant to scratches and abrasions, making it an ideal choice for applications where surface integrity is critical.

Recyclable

Aluminum is a highly recyclable material, making it an eco-friendly choice for many applications. Nearly 75% of all aluminum produced is still in use today, and it can be recycled indefinitely without losing its quality. Recycling aluminum requires less energy than producing it from scratch, making it a sustainable material choice.

| Aerospace

040 Aluminium Sheet is used in the construction of airplanes, rockets, and other aerospace applications due to its lightweight and strength. It is also highly resistant to corrosion and has excellent thermal conductivity, making it an ideal choice for aerospace applications. |

|

| Construction

The material is used in the construction of buildings, bridges, and other structures due to its durability and resistance to corrosion. It is also a popular choice for roofing, siding, and architectural accents due to its lightweight nature and aesthetic appeal. More:https://hw-alu.com/applications/aluminum-sheet-for-construction.html |

|

| Transportation

040 Aluminium Sheet is used in the manufacturing of automobiles, trains, and boats due to its lightweight and strength. It is also highly resistant to corrosion and has excellent thermal conductivity, making it an ideal choice for transportation applications. |

|

| Electronics

The material is used in the manufacturing of electronic devices, including smartphones, laptops, and other devices due to its conductivity and corrosion resistance. It is also used in the construction of heat sinks, which dissipate heat away from electronic components, keeping them cool and extending their lifespan. |

|

040 Aluminium Sheet is available in various sizes and dimensions to meet the needs of different applications. The standard sheet size is 48″ x 96″(4×8 foot aluminum sheet), and it is available in thicknesses ranging from 0.016″ to 0.249″.

040 Aluminum Sheet is available in different grades and alloys to meet specific application needs. The most common grade used for 040 Aluminum Sheet is 3003 aluminum sheet, which offers excellent corrosion resistance and formability. Other grades include 5052, which has higher strength and better corrosion resistance than 3003, and 6061 aluminum, which has excellent machinability and weldability.

040 Aluminum Sheet is manufactured using a process called rolling, which involves passing the metal through a pair of rollers to reduce its thickness. The rolling process can be repeated multiple times until the desired.

040 Aluminum Sheet Products

During the production process, 040 Aluminium Sheet undergoes various quality control checks to ensure that it meets industry standards. These checks include visual inspections, chemical analysis, and mechanical testing. Only materials that pass these checks are considered suitable for use in various applications.

There are several factors that can affect the price of 040 Aluminum Sheet. Here are some of the most common factors:

The cost of aluminum is one of the most significant factors that can impact the price of 040 Aluminum Sheet. The price of aluminum can be influenced by a range of factors, including supply and demand, global economic conditions, and geopolitical events. If the cost of aluminum increases, the price of 040″ Aluminum Sheet is likely to increase as well.

The demand for 040 Aluminum Sheet can also impact its price. If there is a high demand for the material, manufacturers may be able to charge a higher price for it. Conversely, if there is low demand, manufacturers may need to lower their prices to remain competitive.

The production costs associated with producing 040 Aluminium Sheet can also impact its price. This includes costs such as labor, energy, and transportation. If the cost of production increases, the price of the material is likely to increase as well.

The size and quantity of the 040″ Aluminum Sheet that is being purchased can also impact its price. Generally, larger sheets are more expensive than smaller sheets, and purchasing larger quantities can result in lower per-unit costs.

The type of alloy used to produce the 040 Aluminum Sheet can also impact its price. Different alloys have different properties, and some are more expensive to produce than others. For example, 5052 aluminum alloy is more expensive than 3003 aluminum alloy due to its increased corrosion resistance.

As a language model, I don’t have access to specific user data or opinions about 040 Aluminum Sheet. However, based on common applications and usage of the material, here are some potential concerns that users may have:

When it comes to 040 Aluminum Sheet, there are many questions that buyers may have. Here are some of the most common questions and their answers:

What is 040″ Aluminum Sheet?

040 Aluminium Sheet is a type of aluminum sheet that is 0.040 inches thick. It is commonly used in a range of applications, including automotive parts, siding, and roofing.

What are the benefits of using 040 Aluminum Sheet?

040 Aluminum Sheet offers several benefits, including its lightweight nature, corrosion resistance, and durability. It is also easy to work with and can be cut, drilled, and bent to meet specific needs.

What are the different types of 040 Aluminum Sheet?

There are several different types of 040 Aluminum Sheet, including 3003 and 5052 alloys. The type of alloy used will impact the properties of the sheet, including its strength, durability, and corrosion resistance.

How do I determine the right size of 040″ Aluminum Sheet for my project?

The size of 040 Aluminum Sheet that you need will depend on your specific project requirements. Consider factors such as the dimensions of the area that you need to cover, the thickness of the material needed, and any weight limitations that may be in place.

How do I care for and maintain 040 Aluminum Sheet?

To care for and maintain 040 Aluminum Sheet, it is important to avoid exposing it to harsh chemicals and abrasive materials. Regular cleaning with a mild detergent and water can help to keep the sheet looking its best.

5005 aluminum sheet is a medium-strength aluminum alloy plate, which can reach medium and high strength by cold working, and it has good formability

3000 series aluminum alloy is an AL-MG alloy whose main components are aluminum, manganese and a small amount of other elements. It has excellent properties such as good corrosion resistance, processability and weldability.

Flexible packaging aluminum foil is a thin foil made of aluminum that is commonly used in food packaging and pharmaceutical packaging. Unlike hard aluminum foil, flexible packaging aluminum foil is soft and can adapt to various shapes of containers, so it is widely used for packaging food and medicine.

Composite aluminum foil is a functional material composed of aluminum foil and other materials. It has various properties such as antioxidant, heat resistance, corrosion resistance, and heat insulation

Embossed aluminum sheet is an aluminum product that is rolled on the basis of pure aluminum plate or aluminum alloy plate to form various patterns on the surface.

PVD anodizing aluminum mirror sheets is a process where a thin layer of material is deposited onto the surface of the aluminum through a vacuum deposition process.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sirs, I'm looking for a provider of aluminum 7075-T651 in 1.0 or 1.5 mm thickness. We need about 180 plates of 200 mm x 200 mm. Are you able to provide a quote and delivery time for this? Thank you so much in advance. Kind regards, Francisco Silva

Hello, I hope this message meets you well. I have perused your website and I want a detailed price quote for your product; upon your response to this message I will forward more details concerning this order/project to you. I look forward to doing business with you. Warm thanks. Best regards, Ahmet Emir Purchase Manager SER MEKATRONIK SANAYI VE TICARET LTD.STI. Turkgucu O.S.B. Mahallesi 216.Sokak NO:5/1 Corlu / Tekirdag / Turkey Email: [email protected]

I need a quotation for 3000 series aluminum sheets/coils (3104 H19) for tuna can production, food-grade finish, delivery to Mazatlán, Mexico.

I am planning a business trip to China and I am very interested in your aluminium 8011 products for food container production. I would like to visit your factory during my stay in china: See your production lines (foil rolling, annealing, slitting, packing). Discuss specifications (8011-O temper, thickness 0.05–0.08 mm, jumbo roll). Review your quality certificates and export experience. Could you please let me know: Your available dates for a visit The location of your factory If you can provide an invitation letter for my business visa (M visa). Thank you for your kind support. Looking forward to your reply. Best regard: LOUNIS MUSTAPHA company name:TOP BARQUETTE SELECT [email protected] what's up:213 770 91 69 43

Merhaba ; Burak ÜNAL ben. Antalya ' da Ambalaj ve Temizlik ürünleri tedarik eden bir firmanın yetkilisiyim. Ayrıca P.E Streç aktarım işi yapmaktayım. Makinalarımızı 9 ve 10 micron alüminyum folyo aktarımına uyacak şekilde revize edeceğiz. Sizden istediğim, 9 veya 10 micron olacak şekilde 35 cm ve 45 cm jumbo folyolar için fiyat, termin ve şu bilgileri istiyorum ; 35 cm jumbo folyonun ortalama ağırlığı. 45 cm jumbo folyonun ortalama ağırlığı. Deneme olacağı için bu 2 ölçüde minimum sipariş tonajımız ne kadar olması gereklidir. İyi çalışmalar.