PVD anodizing aluminum mirror sheets is a process where a thin layer of material is deposited onto the surface of the aluminum through a vacuum deposition process.

PVD (Physical Vapor Deposition) anodizing aluminum mirror sheets is a process where a thin layer of material is deposited onto the surface of the aluminum through a vacuum deposition process. PVD coating can enhance the appearance, durability, and corrosion resistance of aluminum surfaces, including mirror sheets.

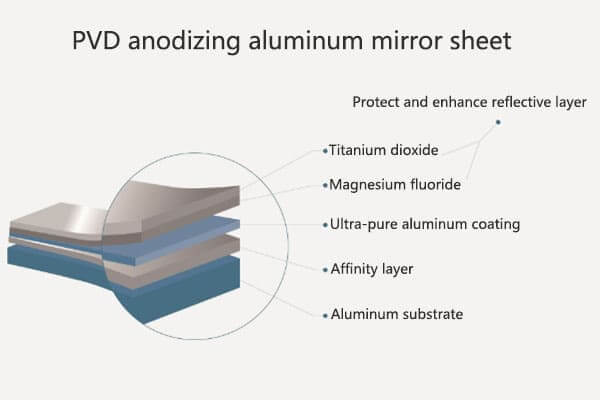

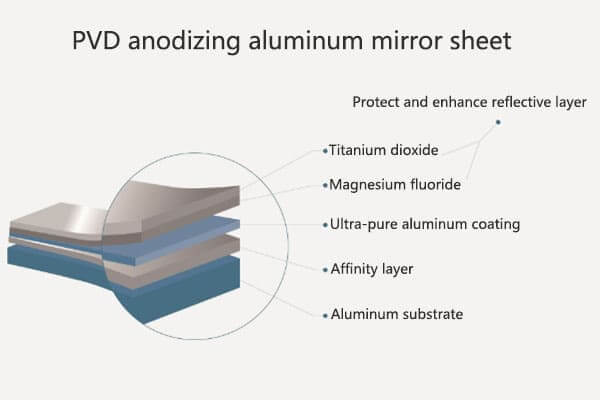

PVD anodizing aluminum mirror sheet

Huawei Aluminum provides PVD anodizing aluminum mirror sheet with a reflectivity of up to 99%. We can adjust the reflectivity of the product by controlling the thickness of PVD.

PVD anodizing aluminum mirror sheet structure

| 1000 series | 2000 series | 3000 series | 5000 series | 6000 series | 7000 series | 8000 series |

| Pure aluminum | Al-Cu | Al-Mn | Al-Mg | Al-Mg-Si | Al-Zn | Al-Fe |

Excellent corrosion resistance:

The anodizing process generates a dense aluminum oxide (Al₂O₃) film on the surface of the aluminum plate, which enhances the aluminum plate’s resistance to the atmosphere, chemical substances and moisture, and significantly improves its corrosion resistance.

High strength and wear resistance:

The high hardness of the anodized film makes the surface of the aluminum plate have good wear resistance and can resist scratches and wear during daily use, maintaining long-term beauty.

Excellent mirror effect:

PVD coating technology can deposit an ultra-thin and uniform metal or alloy film, such as titanium, chromium, zirconium, titanium nitride, etc., on the surface of the aluminum plate to form a mirror effect with high reflectivity. This mirror effect is not only beautiful, but also enhances the brightness and visual openness of the indoor space.

Rich color options:

PVD coating can adjust coating materials and process parameters as needed to achieve a variety of color choices, including primary metal colors, gold, rose gold, black, bronze, etc., to meet personalized and high-end design needs.

Environmentally friendly and pollution-free:

The PVD coating process is a green surface treatment technology with low temperature, low energy consumption and no wastewater discharge. It is environmentally friendly and meets the requirements of modern sustainable development.

Excellent weather resistance:

The PVD coating layer is stable, not easy to fade, and is not affected by ultraviolet radiation. Even if it is used for a long time in an outdoor environment, it can maintain a bright color without peeling or rusting.

Excellent adhesion and abrasion resistance:

There is good bonding force between PVD coating and anodized film, making the coating firmly adhere to the surface of the aluminum plate and not easy to fall off. At the same time, the PVD coating itself has high hardness and wear resistance, further enhancing the scratch resistance of the aluminum plate surface.

Easy to clean and maintain:

The mirror aluminum plate has a smooth surface and is not prone to dust accumulation. When cleaning, you only need to wipe it gently with a soft cloth to restore its original luster, reducing maintenance costs.

Wide applicability:

PVD anodized mirror aluminum sheets are widely used in many fields such as interior and exterior building decoration, high-end furniture, display racks, lighting fixtures, elevator decoration, automotive interiors, and electronic product casings due to their excellent decorativeness and functionality.

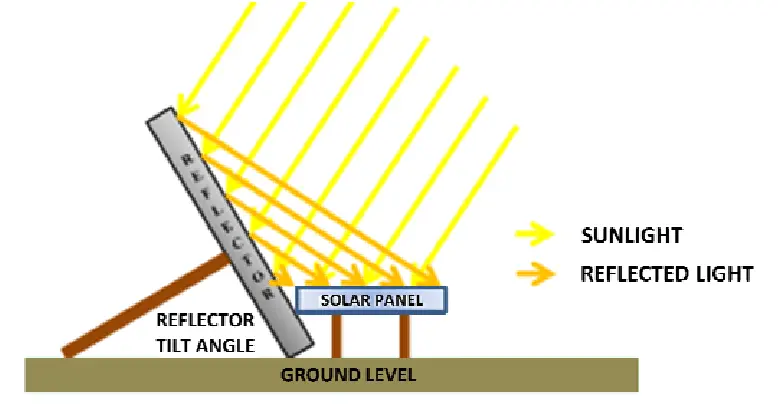

High reflectivity aluminum mirror sheets find diverse applications across various industries due to their exceptional optical properties.Such as, Tubular Daylighting Devices (TDD),solar power systems,satellite reflectors and telescopes, and so on.

Solar reflective panel

Overall, the versatility, durability, and high reflectivity of aluminum mirror sheets make them indispensable in a wide range of applications, driving innovation and efficiency across industries.

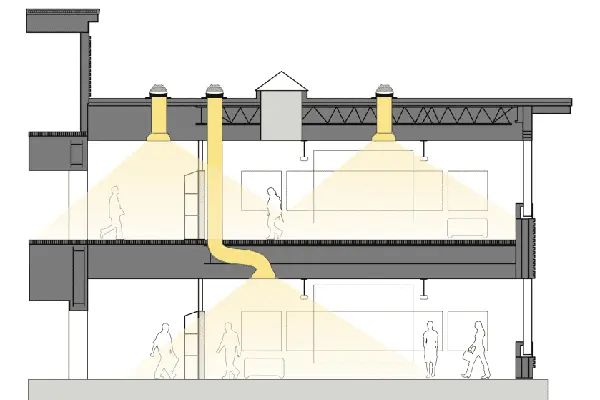

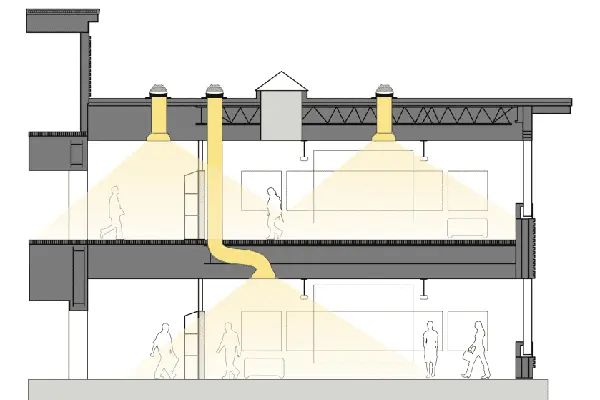

Using PVD anodizing aluminum mirror sheet in Tubular Daylighting Devices (TDD) is a smart choice for maximizing light transmission efficiency.

PVD anodizing aluminum mirror sheet for TDD

These mirror sheets are specifically designed to have excellent reflective properties, which means they can efficiently redirect sunlight into the TDD system, illuminating interior spaces with natural light.

Video

PVD (Physical Vapor Deposition) anodizing aluminum mirror sheets offer several advantages when used in solar power systems:

High reflectivity aluminum mirror sheet for Solar Power System

No matter you have any needs about PVD anodizing aluminum mirror sheet, please contact us and we will solve your problem for you

Whatsapp: https://api.whatsapp.com/send?phone=8618137782032

Email:[email protected]

6016 aluminum plate is part of the 6000-series of aluminum alloys, which are primarily known for their excellent corrosion resistance, good weldability, and ease of formability.

040 Aluminum Sheet is a type of aluminum sheet that has a thickness of 0.04 inches, which is equivalent to 1.016 millimeters. It is a thin and lightweight material

3000 series aluminum alloy is an AL-MG alloy whose main components are aluminum, manganese and a small amount of other elements. It has excellent properties such as good corrosion resistance, processability and weldability.

3003 aluminum sheet is an alloy with very good corrosion resistance and moderate strength, the reason this metal is widely used is because it is affordable and strong.

Diamond plate aluminum sheets 4x8 is available in 6061-T6 and 3003-H14 sizes. they have higher strength, wear resistance, load-bearing, machinability, corrosion resistance, etc. Therefore, popular in construction, manufacturing, vehicles, ships and various fields.

8006 aluminum foil is a specific alloy known for its excellent barrier properties, making it ideal for packaging applications. It provides effective protection against moisture, light, and oxygen, helping to preserve the freshness and quality of food products.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

I am planning a business trip to China and I am very interested in your aluminium 8011 products for food container production. I would like to visit your factory during my stay in china: See your production lines (foil rolling, annealing, slitting, packing). Discuss specifications (8011-O temper, thickness 0.05–0.08 mm, jumbo roll). Review your quality certificates and export experience. Could you please let me know: Your available dates for a visit The location of your factory If you can provide an invitation letter for my business visa (M visa). Thank you for your kind support. Looking forward to your reply. Best regard: LOUNIS MUSTAPHA company name:TOP BARQUETTE SELECT [email protected] what's up:213 770 91 69 43

Merhaba ; Burak ÜNAL ben. Antalya ' da Ambalaj ve Temizlik ürünleri tedarik eden bir firmanın yetkilisiyim. Ayrıca P.E Streç aktarım işi yapmaktayım. Makinalarımızı 9 ve 10 micron alüminyum folyo aktarımına uyacak şekilde revize edeceğiz. Sizden istediğim, 9 veya 10 micron olacak şekilde 35 cm ve 45 cm jumbo folyolar için fiyat, termin ve şu bilgileri istiyorum ; 35 cm jumbo folyonun ortalama ağırlığı. 45 cm jumbo folyonun ortalama ağırlığı. Deneme olacağı için bu 2 ölçüde minimum sipariş tonajımız ne kadar olması gereklidir. İyi çalışmalar.

We are A Commercial Lighting 's parts and accessories Manufacturer in egypt below is our current requirements for production process from aluminum coil (Alloy 1050 temper O thickness 0.3 mm width 25cm=10tons width 29.5cm=6tons width 33.5cm=5tons width 37 cm=5tons kindly send us your best quotation ASAP according to our company below details: Below is our company details : Full legal company name: Focused ligth for industrial investment ., Co address: Plot no 8 - extension of 4th industrial - zone sadat - minofia - egypt Telephone number Ahmed nseem +201016644789 & +201010879400 Eng Moh El shrief : Mob : +2 01016644789 Tax ID number : 699-483-174

I am writing to inquire about the products that your company offers. I am particularly interested in the product listed below: *Aluminum Coil QTY-20 Units Could you please provide me with more information on these products, including pricing, availability, and any additional details that may be relevant? and also quote your ordinary unit price for supplying these product, together with your discount price for the volume purchase of full truck load. Note: Additionally to the above, our standard Payment Terms:Net 15days to 30 days from the date of supply with the supplier's Invoice.

Bonjour, Je souhaiterait savoir si vous faites des feuilles aluminium de grande taille ? dimension souhaiter: 2500mm X 8000mm pour 0,3 épaisseur . je suis un particulier et vivant en France pour la livraison. merci a vous d'avance Cordialement Mr NEVEU