5000 series aluminum alloy is an Al-Mg alloy series with high strength and excellent corrosion resistance. It is commonly used in the manufacturing of marine, oil tanks, ships, automobile, building materials and other fields.

5000 series aluminum alloy is an aluminum alloy series containing 3-5% magnesium. It has high strength and excellent corrosion resistance, and performs well in corrosive environments such as seawater and chloride, so it is often used in manufacturing Marine engineering, oil tanks, ships, automobile manufacturing, building materials and other fields.

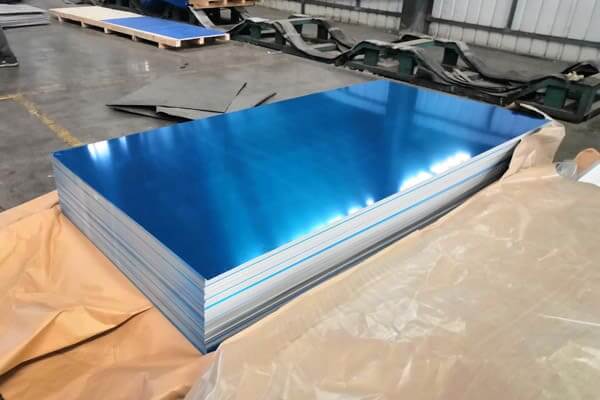

5000 series aluminum alloy sheet

5000 series aluminum alloy materials have become indispensable and important materials in many industries due to their excellent properties.

| Series | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other | Al |

| 5000 | 0.4 | 0.35 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.115 | 0.15 | Remainder |

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other | Al |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.5-1.1 | 0.1 | 0.25 | – | 0.15 | Remainder |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | – | 0.15 | Remainder |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | 0.15 | Remainder |

| 5086 | 0.4 | 0.5 | 0.1 | 0.2-0.7 | 3.5-4.5 | 0.05-0.25 | 0.25 | 0.15 | 0.15 | Remainder |

| 5454 | 0.25 | 0.4 | 0.1 | 0.5-1.0 | 2.4-3.0 | 0.05-0.20 | 0.25 | 0.2 | 0.15 | Remainder |

| 5754 | 0.4 | 0.4 | 0.1 | 0.5 | 2.6-3.6 | 0.3 | 0.2 | 0.15 | 0.15 | Remainder |

| Alloy Type | Density (g/cm³) | Melting Point (℃) | Linear Expansion Coefficient (μm/m·K) | Thermal Conductivity (W/m·K) | Elastic Modulus (GPa) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| 5052 | 2.68 | 607 – 650 | 23.8 | 120 – 140 | 70 | 195 – 305 | 95 – 240 | 1 – 12 |

| 5083 | 2.65 | 570 – 640 | 23.5 | 110 – 140 | 72 | 270 – 365 | 125 – 280 | 2 – 10 |

| 5086 | 2.66 | 570 – 650 | 23.5 | 120 – 140 | 69 | 240 – 325 | 95 – 240 | 3 – 10 |

| 5754 | 2.66 | 600 – 640 | 21.5 | 120 – 150 | 70 | 190 – 270 | 80 – 220 | 4 – 12 |

| 5454 | 2.66 | 585 – 635 | 21.5 | 120 – 150 | 70 | 220 – 305 | 105 – 245 | 1 – 10 |

The main components of the 5000 series aluminum alloy include aluminum, magnesium, silicon, copper, zinc, manganese and other elements. Among them, aluminum is its main component, accounting for more than 95%. In addition, 5000 series aluminum alloys also contain small amounts of impurity elements, such as iron, nickel, titanium, etc. This alloy has the following characteristics:

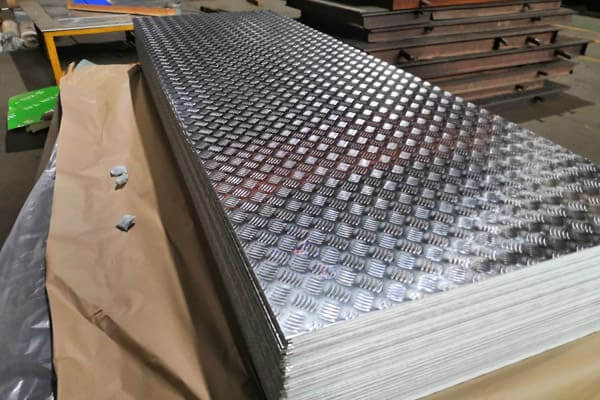

5000 series aluminum alloy tread plate

5005 aluminum alloy is similar to 3003 alloy, with medium strength and good corrosion resistance. Used as conductors, cookware, instrument panels, shells and architectural decorations. The anodized film is brighter than that on 3003 alloy and matches the hue of 6063 alloy. Harmony 5050 thin plate can be used as the lining plate of refrigerators and refrigerators, automobile air pipes, oil pipes and agricultural irrigation pipes; it can also be processed into thick plates, pipes, bars, special-shaped materials and wires, etc.

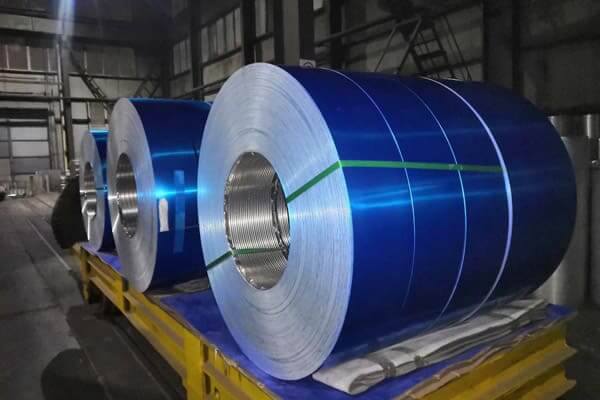

5052 alloy aluminum coil

5052 aluminum This alloy has good forming performance, corrosion resistance, plasticity, pipes and agricultural irrigation pipes; it can also be processed into thick plates, pipes, bars, special-shaped materials and wires, etc. 5052 This alloy has good formability, corrosion resistance, plasticity, fatigue strength and moderate static strength. It is used to manufacture aircraft fuel tanks, oil pipes, as well as sheet metal parts of transportation vehicles and ships, instruments, street lamp brackets and rivets, and hardware. Products, etc.

5083 is used in applications that require high corrosion resistance, good weldability and medium strength, such as ship, automobile and aircraft plate welding parts; pressure vessels, refrigeration devices, television towers, drilling equipment, transportation that require strict fire protection. Transport equipment, missile components, armor, etc.

5086 aluminum alloy sheet plate is used in situations where high corrosion resistance, good weldability and medium strength are required, such as ships and automobiles: aircraft cryogenic equipment is drilled by observation towers. 5086 is used where high corrosion resistance, good weldability and medium strength are required. Strong occasions, such as ships, cars, aircraft, cryogenic equipment, television towers, drilling equipment, transportation equipment, missile parts and decks, etc.

5083 aluminum alloy sheet for boat

5454 aluminum Welded structures, pressure vessels, marine facility pipelines

5754 aluminum alloy is widely used in the automobile manufacturing industry to manufacture body panels, fuel tanks and various structural parts to achieve lightweight design of vehicles; in the field of shipbuilding and marine engineering, its excellent seawater corrosion resistance makes it an ideal choice for ship hulls and offshore platforms. It is an ideal material for port facilities, etc.; in addition, it is often used in rail transit vehicles, aerospace components, chemical equipment, building curtain walls and other fields, showing excellent comprehensive performance and wide application value.

Black 5052 aluminum sheet

With the continuous advancement of science and technology, the demand for aluminum alloy materials is getting higher and higher. 5000 aluminum alloy has a wide range of applications in various fields due to its excellent properties. In the future, with the continuous research and development of new aluminum alloy materials, the application of 5000 series aluminum alloys in various fields will be further expanded, making greater contributions to the development of science and technology in our country.

Packaged 5000 series aluminum alloy sheet

Professional aluminum foil alloy manufacturer, direct selling price supply, the most trustworthy supplier in China best price for sale

In general, aluminum sheet that is thicker than 6mm (0.25 inches) is considered to be thick.

The 5052 anodized mirror plate is a type of aluminum sheet that has undergone an anodization process, resulting in a reflective surface. The material is primarily made from 5052 aluminum alloy, which is known for its excellent corrosion resistance and good formability.

Compared with other alloy foils of series 1, such as 1060 and 1070 aluminum foils, the content of (Fe+Si) in 1100 aluminum foil is higher than both, and the content of Fe is the key factor to improve the strength and toughness

Electronic aluminum foil is a kind of aluminum foil processed by a series of rolling, cleaning and cutting processes of high-purity aluminum ingots. It is a key raw material for the production of aluminum electrolytic capacitors.

5052 Aluminum Disc is an Al-Mg alloy renowned for its excellent corrosion resistance, high fatigue strength, and superior workability.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Our required qty: Aluminium Sheet in coil (620mm X 1.20mm) Qty: 200 MT. Can you give me the number of contact urgently. Thanks Matiur Rahman Director of Technical Sales dept.

Bonjour ; Nous sommes une compagnie de spectacle de rue " compagnie carabosse " nous travaillons avec la flamme . nous sommes à la recherche de tôle reflecteur en aluminium pour pouvoir crée un nouvelle objet à base d'un fil métal enflammé liquide éthanol d' une hauteur environ 1 m . Quels produits avez vous à nous proposez ? Cordialement Fabrice

Hello, I am interested in 3*1500*3500 mm 5754 H111 Checkered Aluminium Plate - Diamond Shape Powermaster Ltd. Moscow, Volokolamskoe shosse 1, str. 1, of. 19, Moscow, 125080

Buenos días, Me interesaría saber el costo de Paneles de nido de abeja de aluminio para usar como refuerzo interior de bandejas, estantes , mesadas que realizamos en acero inoxidable AISI 304. De espesor del panel de 10 y 20 mm, con la piel superior e inferior de aluminio espesor 0.8 mm liso o cepillado o solo el núcleo del nido de abeja de aluminio; con tamaño de celda de 10 o 15 mm ( o estándar ) . tamaño de las planchas de 1500 x 3000 mm o la lo que recomiende para el uso que le quiero dar. Desde ya muchas gracias

Proszę o ofertę na blachę aluminiową grubość 20 mm, w gatunku 1060. 8000 kg