Electronic aluminum foil is a kind of aluminum foil processed by a series of rolling, cleaning and cutting processes of high-purity aluminum ingots. It is a key raw material for the production of aluminum electrolytic capacitors.

Electronic aluminum foil is a kind of aluminum foil processed by a series of rolling, cleaning and cutting processes of high-purity aluminum ingots. It is a key raw material for the production of aluminum electrolytic capacitors.

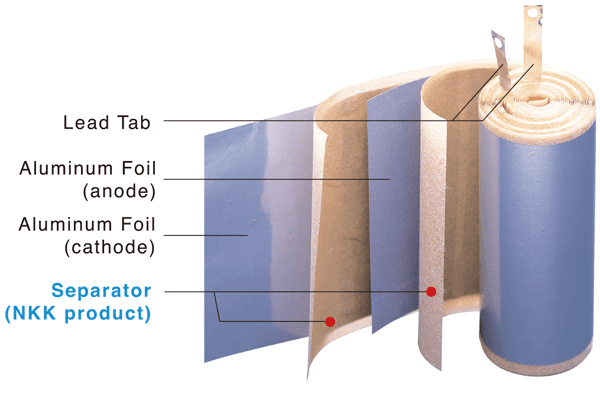

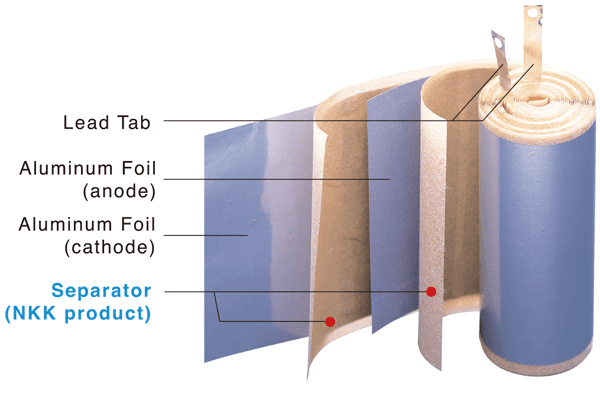

After the aluminum material is processed into foil, the electronic aluminum foil undergoes surface corrosion treatment and re-oxidation treatment, and then is wound to make a capacitor. The aluminum foil before corrosion is called light foil, the aluminum foil after corrosion is called corrosion foil, and the aluminum foil after re-oxidation is called finished foil.

electronic aluminum foil

Electronic aluminum foil refers to light foil and is a key raw material for the production of aluminum electrolytic capacitors. Due to the sequence of the production process, it is divided into electronic aluminum foil and electrode foil. The electrode foil includes corrosion foil and chemical foil.

Electronic aluminum foil and electrolyte together account for 30%-70% of the raw material cost of aluminum electrolytic capacitors (varying with the size of the capacitor). It can store electrical energy and can be used as the positive and negative electrodes of electrolytic capacitors.

As one of the most basic electronic components, aluminum electrolytic capacitors are widely used in various electronic products such as the electronic information industry and home appliances.

They have the characteristics of small size, large capacitance and low cost, especially the price per unit capacitance is the lowest among all The cheapest capacitors, in line with the development trend of low-price information products, are widely used in communications, home appliances, automobiles, electronics, aviation, new materials and other industries. The market demand is huge. At present, aluminum electrolytic capacitor production accounts for 45% of all capacitor production.

electronic aluminum foil jumbo roll

The main products of electronic aluminum foil include 1000 and 3000 series aluminum alloy. Electronic aluminum foil is mainly used in electronic components and other fields. Warwick Aluminum Electronic Foil has a high market share, stable product performance, excellent quality, and high market recognition.

Electronic aluminum foil is high-purity aluminum foil, which is made from refined aluminum (high-purity aluminum) aluminum ingots that are hot-rolled into aluminum sheets, and then further cold-rolled and annealed. The specific production process of electronic aluminum foil includes: melting and casting-soaking-hot rolling-pre-annealing-cold rolling-intermediate annealing-cold rolling-foil rolling-slitting-performance testing-packaging.

| Alloy series | Typical Alloy | Material status | Thickness(mm) | Width(mm) | Length(mm) |

| 1000 series | 1070、1100A | H18 | 0.02-0.055 | 100-1700 | C |

| 3000 series | 3003 |

Electronic aluminum foil can be divided into high-voltage anode foil, low-voltage anode foil, negative electrode foil, etc. The high-voltage anode foil is corroded like pillar holes, the low-voltage anode foil is corroded like sponge, and the anode foil in the medium-voltage section is corroded like moths.

High-voltage anode foil can be divided into two categories, one is high-quality high-voltage foil; the other is ordinary high-voltage foil. The characteristics of high-quality high-voltage anode foil are “two high and one thin”, that is, high purity, high cubic texture and thin surface oxide film.

This type of product is of high quality, but the cost is high. The aluminum purity is >99.99%, the cubic texture is 96%, and the vacuum heat treatment is carried out under the conditions of 10-3pa ~ 10-5Pa. Ordinary high-voltage anode foil is an economical and practical high-voltage anode foil. The aluminum purity is >99.98%, the cubic texture is >92%, and the vacuum heat treatment is carried out under the conditions of 10-1pa ~ 10-2pa.

The production of electronic aluminum foil is a precision processing process, and the quality of the product has an important relationship with the advanced level of raw materials, control systems, and production equipment.

From a global perspective, although China’s electronic aluminum foil production is developing rapidly, European and American companies still have advantages in advanced technology, especially in high-voltage electronic aluminum foil.

capacitor structure diagram

Since electronic aluminum foil products have strict requirements on process technology, equipment technology and production management level, production must strictly follow the process flow and equipment characteristics to produce qualified products.

In recent years, with the advancement of science and technology, the main equipment used in the production of electronic aluminum foil products has been domestically produced. Nowadays, domestic electronic aluminum foil factories use domestic equipment to produce products, and the quality level has caught up with or even exceeded the products produced by Japan and South Korea.

In the choice of control system, the technology possessed by major domestic manufacturers is not very mature, and most of them choose foreign control systems. In terms of technology, domestic production lines and production processes still imitate and continue to use foreign technology, or choose a technical model of cooperation with foreign capital.

capacitor used electronic aluminum foil

In order to continuously improve the product characteristics of aluminum electrolytic capacitors, my country has made many related technical improvements in aluminum foil processing. The use of high-purity, high-performance aluminum foil materials greatly improves the corrosion performance of the material, and at the same time greatly reduces the leakage current of the dielectric oxide film formed;

The development of advanced corrosion and formation processes further increases the specific capacity of the cathode and anode aluminum foils, and the anodic light The leakage current of the foil is further reduced. In order to realize the volume reduction and flattening of capacitors, the processing technology of high specific volume and high strength of chemically formed aluminum foil has made progress in recent years.

| 1. Aluminum foil bumps ▲Aluminum foil bruises refer to the damage caused to the surface or end face of the foil after it collides with other objects during transportation or storage. Bruises are mostly caused by carelessness when packaging aluminum foil. |

Aluminum foil bumps |

| 2. Corrosion ▲The surface of the aluminum foil is in contact with the surrounding medium, and after a chemical reaction or electrochemical reaction occurs, defects will be generated on the surface of the aluminum foil, the surface of the corroded aluminum foil will lose its luster, and gray corrosion products will be produced in severe cases. The corroded aluminum foil will have a great impact on the aesthetics of the products produced by the terminal. |

Corrosion |

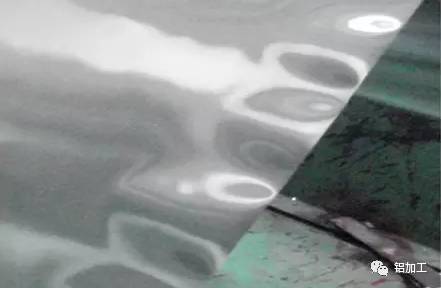

| 3. Surface air bubbles ▲Aluminum foil with surface bubble defects will have irregular circular or strip-shaped cavities on the surface of the foil; the edges of the protrusions are smooth, the two sides are asymmetrical, and the distribution is irregular. Unbalanced force is likely to cause breakage and shutdown. |

Surface air bubbles |

| 4. Dark side stripes ▲Dark side stripes mostly appear on double-joint products. There are obvious light and dark stripes along the rolling direction on the dark side, which affects the appearance. |

Dark side stripes |

| 5.Imprints ▲ There are many situations that will cause marks on the surface of the aluminum foil, such as defects on the surface of the roller or guide roller or dirt such as metal shavings stuck on the surface, the surface of the sleeve or tube core is not clean or there are smooth bumps in the area, or the foil is rolled when it is coiled.There are foreign objects stuck on the surface, etc. There are usually single or periodic depressions or ridges on the surface of the foil where marks appear, which are easy to identify. |

Imprints |

| 6. Oil spots ▲Common aluminum foil oil stains are formed after annealing and are generally light yellow, brown, or yellowish-brown stains. |

Oil spots |

| 7. Remove oil and dirt ▲To check whether the degreasing is clean, generally after annealing, use the water brushing method to test the degreasing level. If it does not reach the level specified in the water brushing test, there may be oil on the aluminum foil. |

Remove oil and dirt |

| 8.Split edge ▲The phenomenon of longitudinal cracks on the aluminum foil surface is called cracked edges. In severe cases, obvious gaps can be seen on the edges. |

Split edge |

| 9. Poor plate shape ▲Due to uneven deformation, local unevenness occurs on the surface of the foil, which is called poor shape. According to the location where the defect occurs, it is divided into middle waves, edge waves, two-rib waves and compound waves.The waves on the sides are called side waves (as shown in the figure), and the waves in the middle are called middle waves. Both are called compound waves, and waves that are neither in the middle nor on the sides are called two-ribbed waves. |

Split edge |

| 10. Adhesion ▲A single sheet of aluminum foil roll is not easy to open, and when multiple sheets are opened, it will be hardened, and the free-falling length of the product cannot meet the standard requirements. In serious cases, the single sheet cannot be opened, and the adhesion of aluminum foil will seriously affect the production of products. |

Adhesion |

| 11. Holes ▲The surface of the foil is prone to holes. |

Holes |

| 12. loose volume ▲Because the winding is not tight during slitting, when the foil is held upright along the direction of the die, the foil will be shifted between layers; when the foil is pressed with fingers, local depressions may occur. |

loose volume |

| 13. Burr ▲After cutting, there are thorns of different sizes on the edge of the foil. |

Burr |

| 14. Split level ▲The end face layers of aluminum foil rolls move irregularly, causing the end face to be uneven. |

Split level |

| 15. Tower shape ▲The misalignment between the aluminum foil end layers causes a tower-shaped deviation, which is called a tower shape. The tower shape is a special case of split levels, with the sides looking like a spire. |

Tower shape |

Discover premium PVDF color coated aluminium sheets with excellent durability, UV resistance, and vibrant color retention. Perfect for architectural, industrial, and decorative applications.

5005 aluminum coil refers to the 5005 aluminum plate after being cast and rolled and then processed into a coil shape by drawing and bending,

Discover LDPE composite aluminum foil, designed for superior moisture resistance, thermal insulation, and versatile applications in packaging, construction, and more.

Discover the perfect blend of strength and aesthetics with black aluminum checker plate. Ideal for flooring, ramps, and decorative features, this lightweight material ensures safety and style in any setting.

Our 3003 Aluminum foil products have been exported to Australia, Morocco, Syria, Kuwait, Turkey, Saudi Arabia, UAE, Iraq, Jordan, Germany, Poland, Spain, Brazil, etc. We sincerely welcome you to visit our factory.

The properties of 3003 aluminum circle make it ideal for use in multiple markets including the cookware, automotive and lighting industries

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

2000x3000mm aluminum sheet Price and transport

Our required qty: Aluminium Sheet in coil (620mm X 1.20mm) Qty: 200 MT. Can you give me the number of contact urgently. Thanks Matiur Rahman Director of Technical Sales dept.

Bonjour ; Nous sommes une compagnie de spectacle de rue " compagnie carabosse " nous travaillons avec la flamme . nous sommes à la recherche de tôle reflecteur en aluminium pour pouvoir crée un nouvelle objet à base d'un fil métal enflammé liquide éthanol d' une hauteur environ 1 m . Quels produits avez vous à nous proposez ? Cordialement Fabrice

Hello, I am interested in 3*1500*3500 mm 5754 H111 Checkered Aluminium Plate - Diamond Shape Powermaster Ltd. Moscow, Volokolamskoe shosse 1, str. 1, of. 19, Moscow, 125080

Buenos días, Me interesaría saber el costo de Paneles de nido de abeja de aluminio para usar como refuerzo interior de bandejas, estantes , mesadas que realizamos en acero inoxidable AISI 304. De espesor del panel de 10 y 20 mm, con la piel superior e inferior de aluminio espesor 0.8 mm liso o cepillado o solo el núcleo del nido de abeja de aluminio; con tamaño de celda de 10 o 15 mm ( o estándar ) . tamaño de las planchas de 1500 x 3000 mm o la lo que recomiende para el uso que le quiero dar. Desde ya muchas gracias