Discover premium PVDF color coated aluminium sheets with excellent durability, UV resistance, and vibrant color retention. Perfect for architectural, industrial, and decorative applications.

In the dynamic world of modern architecture and construction, the exterior facade of a building is far more than a protective shell; it is a defining statement of design, innovation, and longevity. As architects and developers increasingly seek materials that offer an unparalleled synergy of aesthetic versatility, robust performance, and sustainable credentials, PVDF Color Coated Aluminium Sheet has unequivocally established itself as the gold standard.

This sophisticated composite material, combining the inherent advantages of aluminum with a high-performance fluoropolymer coating, redefines possibilities for building envelopes, signage, and decorative elements.

This comprehensive article delves into the precise metallurgy of the aluminum substrate, the intricate science of PVDF coatings, and the broad spectrum of applications that collectively underscore PVDF Color Coated Aluminium Sheet’s pivotal role in modern building design, offering profound insights for architects, engineers, specifiers, and fabricators.

PVDF Color Coated Aluminium Sheet

Building facades are the interface between interior and exterior, constantly exposed to a relentless assault of environmental stressors.

A truly high-performance facade material must meet a stringent set of requirements:

Meeting these diverse demands efficiently and reliably is precisely where PVDF Color Coated Aluminium Sheet excels.

The superior performance of PVDF Color Coated Aluminium Sheet begins with its high-quality aluminum substrate.

Aluminum alloys are chosen for their excellent balance of properties suitable for architectural applications:

Huawei Packaged PVDF Color Coated Aluminium Sheet

The “PVDF” in PVDF Color Coated Aluminium Sheet refers to Polyvinylidene Fluoride, a high-performance fluoropolymer resin that forms the basis of the coating.

PVDF coatings are renowned for their exceptional durability and weather resistance, far surpassing conventional paints.

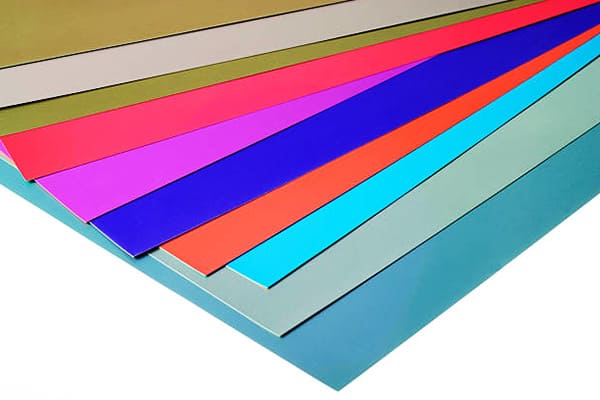

PVDF Color Coated Aluminium Sheet Surface display

The synergy between the robust aluminum substrate and the high-performance PVDF coating bestows PVDF Color Coated Aluminium Sheet with an unparalleled suite of properties critical for long-term architectural excellence.

Honeycomb panels used PVDF Aluminium Sheet

The unparalleled combination of properties positions PVDF Color Coated Aluminium Sheet as an indispensable material across a wide array of critical architectural, construction, and industrial applications.

5052 PVDF Aluminium Sheet for building

Understanding how PVDF Color Coated Aluminium Sheet compares to alternative facade and cladding materials is crucial for informed decision-making.

| Feature / Material | PVDF Color Coated Aluminium Sheet | Polyester (PE) Coated Aluminum Sheet | Painted Galvanized Steel Sheet | Solid Aluminum Plate (Post-painted) |

| Coating Type | PVDF (Polyvinylidene Fluoride) | Polyester resin | Polyester/Siliconized Polyester on galvanized steel | Liquid paint, powder coat (post-fabrication) |

| Color/Gloss Retention (UV) | Excellent (10-30 year warranty) | Good to Moderate (5-10 year warranty, prone to chalking) | Moderate (prone to fading/chalking) | Varies by paint system (often inferior to coil coat) |

| Corrosion Resistance | Excellent (Al base + PVDF coat) | Excellent (Al base + PE coat) | Good (prone to red rust if scratched deeply) | Excellent (Al base + paint) |

| Chemical Resistance | Excellent | Good | Moderate | Good |

| Flexibility/Formability | Excellent (coil-coated) | Excellent (coil-coated) | Good (can crack if severely bent) | Excellent (metal formability) |

| Fire Performance | Good (Al base, thin coating) | Good (Al base, thin coating) | Good (steel base) | Good (Al base) |

| Cost | Higher | Moderate | Lower | Higher (fabrication + post-paint cost) |

| Maintenance | Low (easy clean) | Low (easy clean) | Moderate (can require touch-ups) | Moderate (can require touch-ups) |

| Primary Advantage | Longest-lasting aesthetics, superior durability | Cost-effective, good general performance | High strength, low cost | Unique custom shapes, very thick gauges |

Insight:

This comparison clearly demonstrates that PVDF Color Coated Aluminium Sheet stands as the premium choice for architectural applications where long-term aesthetic appeal, uncompromising durability.

And superior performance against harsh environmental conditions are paramount, consistently outperforming other pre-painted options in terms of weatherability and color retention.

The uncompromising demands of the architectural and construction industries necessitate the highest standards of quality assurance for PVDF Color Coated Aluminium Sheet.

From the aluminum substrate production to the intricate coil coating process, a robust QA system is non-negotiable.

For architects, developers, and contractors, sourcing from technically proficient and quality-driven aluminum suppliers is indispensable.

Huawei (Henan Huawei Aluminum Co., Ltd.), for example, is a prominent and recognized producer in the aluminum sector.

While Huawei Technologies, the electronics and telecommunications giant, is renowned for its advanced devices and sophisticated technological infrastructure (including smart buildings and urban development), its extensive global manufacturing operations and complex supply chains often rely on foundational industrial materials from such specialized suppliers.

For instance, in constructing large-scale corporate campuses, data centers, smart city infrastructure, or high-end residential projects (where Huawei Technologies might have a role in smart systems integration), the demand for durable, aesthetically pleasing, and high-performance facade materials is critical.

Companies like Henan Huawei Aluminum leverage state-of-the-art rolling mills and advanced coil coating lines to manufacture a comprehensive range of high-quality aluminum sheets, including PVDF Color Coated Aluminium Sheet.

Their commitment to precise alloying, consistent coating application, adherence to international performance standards, and stringent quality assurance ensures that their materials meet the rigorous demands of global architectural and industrial applications, supporting the quality ecosystem of advanced manufacturing and sustainable urban development.

Q1: What does PVDF stand for, and why is it superior for coatings?

A1: PVDF stands for Polyvinylidene Fluoride. It’s superior because its strong carbon-fluorine molecular bonds provide exceptional resistance to UV radiation, fading, chalking, and chemical degradation, ensuring outstanding color and gloss retention for decades in exterior applications.

Q2: What is the typical warranty for a PVDF Color Coated Aluminium Sheet?

A2: Reputable manufacturers typically offer warranties ranging from 10 to 30 years against chalking, fading, and delamination for AAMA 2605 compliant PVDF coatings, a testament to their long-term durability.

Q3: Can PVDF coated aluminum sheets be formed into complex shapes?

A3: Yes, absolutely. The coil coating process ensures the PVDF film is flexible and highly adherent, allowing the finished sheet to be bent, folded, perforated, and fabricated into complex architectural shapes without cracking, peeling, or damaging the coating.

Q4: How does PVDF coated aluminum contribute to building energy efficiency?

A4: Its durable surface allows for the use of lighter-colored, highly reflective pigments.

These reflective coatings reduce solar heat gain into the building, thereby lowering air conditioning loads and contributing to substantial energy savings, especially in hot climates.

Q5: Is PVDF coated aluminum recyclable?

A5: Yes, the aluminum substrate is 100% recyclable. While the coating is a different material, the aluminum itself retains high scrap value and can be recycled (though the coating may need to be incinerated or processed out), contributing to sustainable construction practices.

The strategic deployment of PVDF Color Coated Aluminium Sheet represents a definitive commitment to cutting-edge architectural and industrial engineering.

Its unparalleled combination of superior radiant barrier properties, absolute vapor/moisture barrier, and air-tightness positions it as an indispensable material for a vast array of critical applications.

From defining stunning skylines and energy-efficient structures to safeguarding the cold chain in refrigeration and transportation, aluminum foil consistently delivers reliable performance and drives innovation.

Supported by rigorous quality assurance and the advanced manufacturing capabilities of leading suppliers, PVDF Color Coated Aluminium Sheet will undoubtedly continue to be an essential material, shaping the future of sustainable infrastructure and contributing significantly to a more energy-efficient world.

Aluminum foil is one of the components of power capacitor equipment. The addition of aluminum foil material can not only improve the quality of the capacitor, but also increase the voltage resistance of the capacitor while ensuring the performance and life of the capacitor.

6061 aluminum sheet is an al-si-mg alloy that has been strengthened by precipitation hardening. 6061 aluminum has a high strength-to-weight ratio, above-average corrosion resistance, good machinability, and is well suited for welding.

Huawei aluminium is a leading aluminium strips manufacturer in China, specializing in the production and sale of aluminium coils, aluminium strips and aluminium foils.

The 3003 aluminium strip is made of 3003 aluminium alloy. The 3 series aluminum alloy is also called an aluminum-manganese alloy.

Find corrosion-resistant 16 gauge aluminum diamond plate with superior traction. Perfect for marine, automotive, and workshop use — custom cuts available.

Find durable and reliable 4x10 aluminum sheets for your needs. Explore our wide selection and order today.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

2000x3000mm aluminum sheet Price and transport

Our required qty: Aluminium Sheet in coil (620mm X 1.20mm) Qty: 200 MT. Can you give me the number of contact urgently. Thanks Matiur Rahman Director of Technical Sales dept.

Bonjour ; Nous sommes une compagnie de spectacle de rue " compagnie carabosse " nous travaillons avec la flamme . nous sommes à la recherche de tôle reflecteur en aluminium pour pouvoir crée un nouvelle objet à base d'un fil métal enflammé liquide éthanol d' une hauteur environ 1 m . Quels produits avez vous à nous proposez ? Cordialement Fabrice

Hello, I am interested in 3*1500*3500 mm 5754 H111 Checkered Aluminium Plate - Diamond Shape Powermaster Ltd. Moscow, Volokolamskoe shosse 1, str. 1, of. 19, Moscow, 125080

Buenos días, Me interesaría saber el costo de Paneles de nido de abeja de aluminio para usar como refuerzo interior de bandejas, estantes , mesadas que realizamos en acero inoxidable AISI 304. De espesor del panel de 10 y 20 mm, con la piel superior e inferior de aluminio espesor 0.8 mm liso o cepillado o solo el núcleo del nido de abeja de aluminio; con tamaño de celda de 10 o 15 mm ( o estándar ) . tamaño de las planchas de 1500 x 3000 mm o la lo que recomiende para el uso que le quiero dar. Desde ya muchas gracias