Aluminum foil is one of the components of power capacitor equipment. The addition of aluminum foil material can not only improve the quality of the capacitor, but also increase the voltage resistance of the capacitor while ensuring the performance and life of the capacitor.

Aluminum foil is one of the components of power capacitor equipment. The addition of aluminum foil material can not only improve the quality of the capacitor, but also increase the voltage resistance of the capacitor while ensuring the performance and life of the capacitor. Next, let’s talk about the role of aluminum foil in power capacitors to some companies that don’t know the situation.

The aluminum foil in the capacitor is the key basic raw material of the aluminum electrolytic capacitor. It is the part with the highest technical content and added value in the entire aluminium foil for electrolytic capacitor. The quality of aluminum foil directly affects the quality of its downstream products, aluminum electrolytic capacitors, and in turn affects the quality of the final product.

Aluminium foil for electrolytic capacitor

With the advancement of modern science and technology and the continuous improvement of capacitor performance, aluminum electrolytic capacitors have been widely used in consumer electronics, communication products, computers and peripheral products, new energy, automation control, automobile industry, optoelectronic products, high-speed railway and aviation, and military equipment.

In electrolytic capacitors, it is customary to call the negative electrode foil cathode foil. Since the oxide film on the surface of the cathode foil is very thin, increasing the surface area of the cathode foil has little impact on high-voltage capacitors, but it has a greater impact on low-voltage capacitors.

In electrolytic capacitors, it is customary to call the negative electrode foil cathode foil. Since the oxide film on the surface of the cathode foil is very thin, increasing the surface area of the cathode foil has little impact on high-voltage capacitors, but it has a greater impact on low-voltage capacitors.

| Alloy: | 1070, 3003 |

| Thickness: | 0.012-0.05mm |

| Width: | 100-1700mm |

| Usage: | Widely used in household appliances, computers, communications, industrial control, electric vehicles, electric locomotives and military and aerospace equipment. |

The demand for electrolytic capacitors is strong and the quality requirements are high. During the production process, the surface quality, temperature, grain structure, composition, etc. of the negative electrode foil should be strictly controlled to ensure excellent product performance.

Compared with other types of capacitors, aluminum electrolytic capacitors have the advantages of large unit volume capacity, large rated capacity, high working power plant strength, self-healing effect, and controllable dielectric layer thickness. Therefore, they are widely used in basic components of the electronics industry. is being manufactured and has been recognized by the industry.

First of all, aluminum electrolytic capacitors have a large capacitance per unit volume. Compared with other types of capacitors, the capacity per unit volume may be more than ten to dozens of times, and the electrolyte thickness of aluminum electrolytic capacitors is also tens to hundreds of times that of other capacitors. times.

Aluminium foil production

Secondly, aluminum electrolytic capacitors have a large rated capacity. Due to the large thickness of the oxide film of aluminum electrolytic capacitors, it is easy to expand the area. The rated capacitance of the electrolytic capacitor can be increased according to product manufacturing requirements.

Finally, electrolytic capacitors also have a self-healing effect. If the capacitor electrolyte is damaged, the acid ions in the electrolyte can block the damaged location in a short time, thereby restoring the electrolytic capacitor to its normal state. This increases the risk to a certain extent. Application range of electrolytic capacitors.

It is precisely these advantages that make electrolytic capacitors stand out from the competition with other capacitors. They are widely used in the fields of automotive electronics and frequency conversion technology, and their market share is also increasing year by year.

Modern electronic equipment is updated very quickly. Each change places higher requirements on the performance of electrolytic capacitors. In order to meet the needs of the development of the electronics industry, electrolytic capacitors must ensure the bending strength of corrosion filters. , so that the specific capacity of electrolytic capacitors continues to increase, which requires electrolytic capacitors to be improved in the direction of specific capacity and small volume.

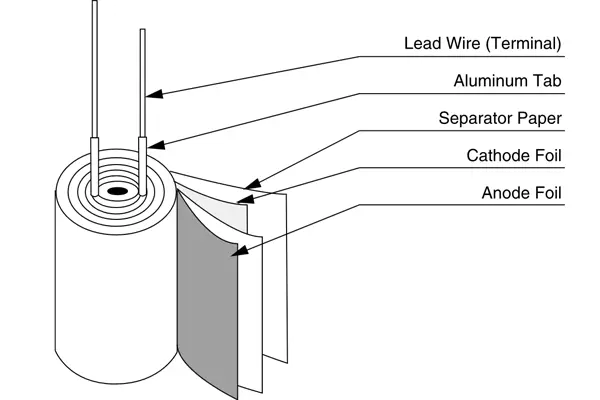

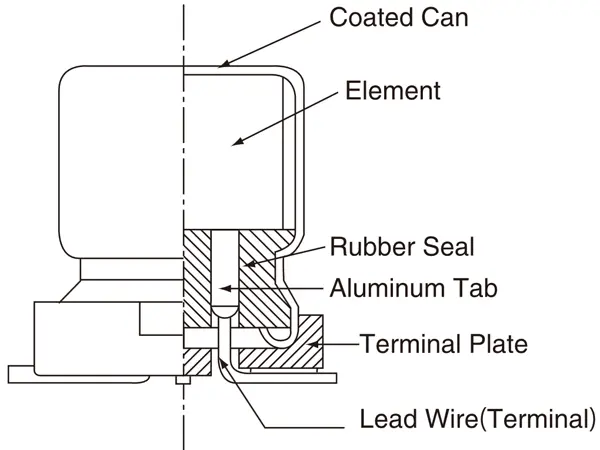

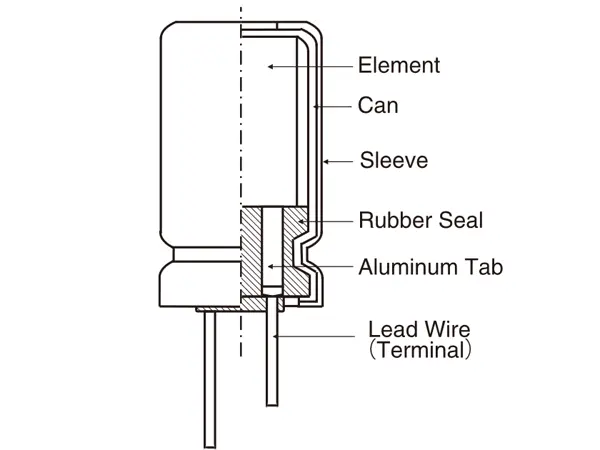

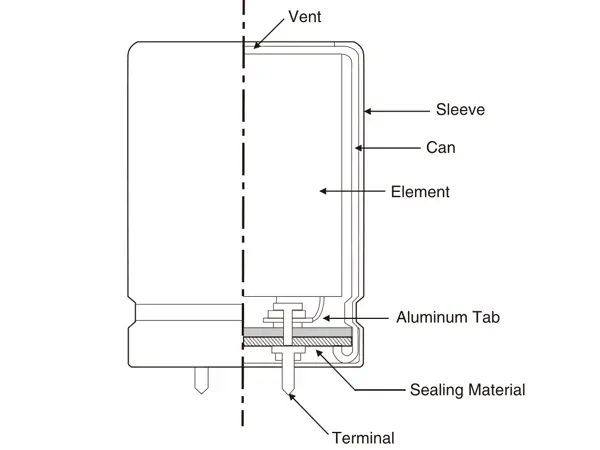

Basic model of element

First of all, researchers should have a clear understanding of the structure of aluminum electrolytic capacitors. The structure of electrolytic capacitors consists of two parts. The first part is the aluminum shell and the sealant cover. This is the external component of the electrolytic capacitor, usually made of anode aluminum foil. It is wound with the cathode aluminum foil. There is a layer of aluminum oxide film on the surface of the anode aluminum foil, which plays a role in withstanding voltage. Therefore, the external structure of the electrolytic capacitor determines the life and capacitance of the electrolytic capacitor.

|

|

|

| Surface Mount Type | Radial Lead Type | Snap-in Type |

The aluminum foil of electrolytic capacitors mainly expands the effective surface area through the corrosion process, thus increasing the capacitance volume of electrolytic capacitors. The specific volume of electrolytic capacitors is affected by the composition of the aluminum-based material, the state of the aluminum-based material, and the corrosion process.

Aluminium foil packaging

Therefore, in order to increase the effective surface area of the electrolytic capacitor, relevant staff need to conduct in-depth research on the relationship between the aluminum foil expansion of the electrolytic capacitor and the corrosion process, and clarify the corrosion process. The influence on the expansion of aluminum foil of electrolytic capacitors.

3003 curtain wall aluminum sheet is the outer wall of a building. It is a lightweight wall of large high-rise buildings and has a certain decorative effect.

Painted aluminum coil (Coated aluminum coil) is a popular material choice for construction, transportation, and signage due to its lightweight, durability, and versatility.

Aluminum strip for transformer means that aluminum strip is used as conductive material in the high and low voltage windings of dry-type transformers and oil-immersed transformers.

1100 aluminium circle is rolled from 1100 aluminum coil as raw material, which belongs to ordinary industrial pure aluminum with aluminum content of 99.0%.

Aluminum circle for cookware bottoms are normally called "aluminum disc" or "aluminum disk." these are circular portions of aluminum which might be used because the base or backside of various forms of cookware, which includes pots, pans, and strain cookers.

Explore the unique properties, manufacturing processes, and wide-ranging applications of 1060 aluminum foil. Learn why this high-purity alloy is essential in packaging, electronics, HVAC, and more.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

I am planning a business trip to China and I am very interested in your aluminium 8011 products for food container production. I would like to visit your factory during my stay in china: See your production lines (foil rolling, annealing, slitting, packing). Discuss specifications (8011-O temper, thickness 0.05–0.08 mm, jumbo roll). Review your quality certificates and export experience. Could you please let me know: Your available dates for a visit The location of your factory If you can provide an invitation letter for my business visa (M visa). Thank you for your kind support. Looking forward to your reply. Best regard: LOUNIS MUSTAPHA company name:TOP BARQUETTE SELECT [email protected] what's up:213 770 91 69 43

Merhaba ; Burak ÜNAL ben. Antalya ' da Ambalaj ve Temizlik ürünleri tedarik eden bir firmanın yetkilisiyim. Ayrıca P.E Streç aktarım işi yapmaktayım. Makinalarımızı 9 ve 10 micron alüminyum folyo aktarımına uyacak şekilde revize edeceğiz. Sizden istediğim, 9 veya 10 micron olacak şekilde 35 cm ve 45 cm jumbo folyolar için fiyat, termin ve şu bilgileri istiyorum ; 35 cm jumbo folyonun ortalama ağırlığı. 45 cm jumbo folyonun ortalama ağırlığı. Deneme olacağı için bu 2 ölçüde minimum sipariş tonajımız ne kadar olması gereklidir. İyi çalışmalar.

We are A Commercial Lighting 's parts and accessories Manufacturer in egypt below is our current requirements for production process from aluminum coil (Alloy 1050 temper O thickness 0.3 mm width 25cm=10tons width 29.5cm=6tons width 33.5cm=5tons width 37 cm=5tons kindly send us your best quotation ASAP according to our company below details: Below is our company details : Full legal company name: Focused ligth for industrial investment ., Co address: Plot no 8 - extension of 4th industrial - zone sadat - minofia - egypt Telephone number Ahmed nseem +201016644789 & +201010879400 Eng Moh El shrief : Mob : +2 01016644789 Tax ID number : 699-483-174

I am writing to inquire about the products that your company offers. I am particularly interested in the product listed below: *Aluminum Coil QTY-20 Units Could you please provide me with more information on these products, including pricing, availability, and any additional details that may be relevant? and also quote your ordinary unit price for supplying these product, together with your discount price for the volume purchase of full truck load. Note: Additionally to the above, our standard Payment Terms:Net 15days to 30 days from the date of supply with the supplier's Invoice.

Bonjour, Je souhaiterait savoir si vous faites des feuilles aluminium de grande taille ? dimension souhaiter: 2500mm X 8000mm pour 0,3 épaisseur . je suis un particulier et vivant en France pour la livraison. merci a vous d'avance Cordialement Mr NEVEU