Painted aluminum coil (Coated aluminum coil) is a popular material choice for construction, transportation, and signage due to its lightweight, durability, and versatility.

Painted aluminum coil refers to a coil of aluminum that has been coated with a layer of paint or coating material, also called coated aluminum coil. Aluminum coil is a long, flat, continuous metal sheet wound into a coil shape, and it is commonly used in various industries due to its lightweight, durability, and corrosion resistance properties.

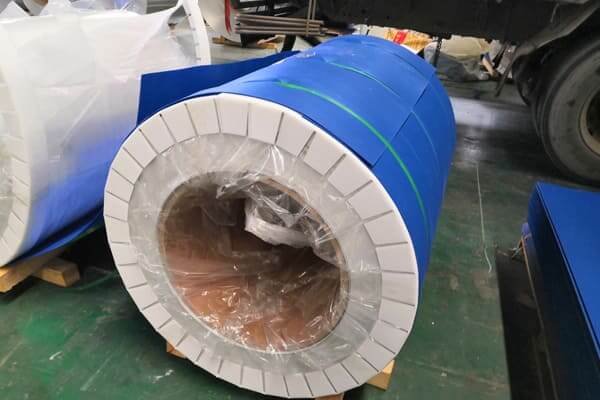

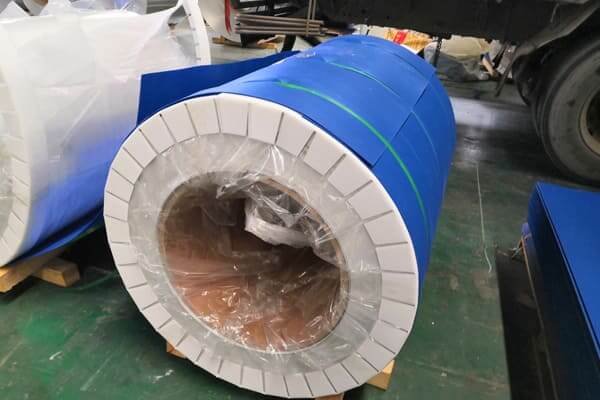

painted aluminum coil

The process of painting aluminum coil involves applying a coating material onto the surface of the aluminum sheet or strip. The coating can be a liquid paint or a powder coating, and it is typically applied through methods such as coil coating or spray coating. The coating material can be chosen based on the desired aesthetic appearance, protection against corrosion, or specific functional requirements.

Painted aluminum coils can be simply classified according to the coating:

polyester-coated(PE) aluminum coils

fluorocarbon-coated(PVDF) aluminum coils

polyester-coated(one side) + fluorocarbon-coated(other side) aluminum coils

| Paint | PE (Polyester), PVDF |

| Coating Thickness | Front side: ≥ 18 um(PE), ≥25 um(PVDF) Back side: 8~10 um (PE or EP) |

| Coating Color | RAL colors, or by confirmed sample (customized) |

Painted aluminum coil offers several benefits, making it a popular choice for various industries and applications. Here are some of the key advantages:

Aesthetic Appeal: Painted aluminum coil provides a wide range of color options, allowing for customization and design flexibility. It enables architects, designers, and manufacturers to create visually appealing products and structures. The paint coating can be applied in different finishes, such as gloss, matte, or textured, further enhancing the aesthetics.

Corrosion Resistance: Aluminum itself is highly resistant to corrosion, and when coated with a paint or coating material, its corrosion resistance is further enhanced. The painted coating acts as a protective barrier, preventing moisture, chemicals, and other corrosive elements from reaching the underlying aluminum surface. This makes painted aluminum coil suitable for outdoor applications and in environments with high humidity or exposure to harsh weather conditions.

Durability: The combination of aluminum’s inherent strength and the protective paint coating makes painted aluminum coil highly durable. It can withstand mechanical stresses, impacts, and abrasion, reducing the risk of surface damage. The durability of painted aluminum coil ensures longevity and minimizes the need for frequent maintenance or replacement.

Lightweight: Aluminum is a lightweight material, and this property is retained even when it is coated with paint. Painted aluminum coil offers a high strength-to-weight ratio, making it advantageous for applications where weight reduction is crucial, such as in transportation (e.g., automotive, aerospace) or when constructing lightweight structures.

Color Coated Aluminum Coil Production

Energy Efficiency: Painted aluminum coil can contribute to energy efficiency in various ways. The light-colored or reflective coatings used on the aluminum surface can help to reduce heat absorption, keeping the coated material cooler. This can be beneficial for buildings, vehicles, or appliances, leading to lower energy consumption for cooling purposes.

Sustainability: Aluminum is a recyclable material, and painted aluminum coil can be recycled as well. The coating can be removed, and the aluminum can be reused or processed for remanufacturing. Recycling aluminum requires significantly less energy compared to primary production, making painted aluminum coil an environmentally friendly choice.

Versatility: Painted aluminum coil can be formed, bent, or shaped without cracking or losing its coating integrity. This versatility allows for its use in various fabrication processes, including roll forming, stamping, and bending. It can be easily integrated into different products and applications, offering design flexibility and ease of manufacturing.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: Each |

Others: Total |

Al:Min. |

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | – | 0.05 | 0.03 | 0.03 | – | 99.50 |

| 1050A | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | – | 0.07 | 0.05 | 0.03 | – | 99.50 |

| 1100 | 0.95 Si + Fe | 0.05~0.20 | 0.05 | – | – | 0.10 | – | 0.05 | 0.15 | 99.0 | |

| 3003 | 0.60 | 0.70 | 0.05~0.20 | 1.0~1.5 | – | – | 0.10 | – | 0.05 | 0.15 | remainder |

| 3105 | 0.60 | 0.70 | 0.30 | 0.3~0.8 | 0.2~0.8 | 0.20 | 0.40 | 0.10 | 0.05 | 0.15 | remainder |

| 5005 | 0.30 | 0.70 | 0.20 | 0.20 | 0.5~1.1 | 0.1 | 0.25 | – | 0.05 | 0.15 | remainder |

| 5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2~2.8 | 0.15~0.35 | 0.10 | – | 0.05 | 0.15 | remainder |

| Product | Color Coated Aluminum Coil |

| Property | Anti-Corrosion, Heat Resistant |

| Surface | Color Coated Coil |

| Production Process | Cold Rolled, Hot Rolled |

| Internal Diameter | 300mm,405mm,505mm or per request |

| Temper | O, H14, H24,H32,H112 Etc;T4,T651 Etc. |

| Thickness | 0.3mm – 60mm |

| Width | 600mm – 2600mm |

| Coil Weight | 2-4 tons |

| MOQ | 6 tons (According to specifications) |

| Difference | Coated Aluminum Coil | Prepainted Steel Coil |

|---|---|---|

| Durability | 25-40years | 15years around |

| Weight | Density: 2.71g/cm3 Lighter, around one-third of Steel | Density: 7.85g/cm3 |

| Strength & Rigidity | In Middle Level, good enough for house construction | Better |

| Appearance | Much more smooth than steel | smooth |

| Anti-thunder property | Anti-thunder | No anti-thunder property |

| Tile forming | It has good welding property and keep physical property in low temperature | It has cold shortness. In low temperature, it is easy to break. |

| Cost performance | High cost performance. Light weight,water-proof, easy bending, good stereoscopic vision; | Weight is three times of aluminum; middle level water-proof property; |

| Recovery Value | High recovery Value, 70% of original value | No recovery Value |

| Feature | The meters per ton is three times longer than Steel; | Comparative cheaper price |

The durability and quality of painted aluminum coil can be influenced by various factors. Here are some key factors that can affect the longevity and overall performance of painted aluminum coil:

Painted aluminum coil finds applications in various industries, including construction, automotive, aerospace, electronics, and signage. In construction, it is commonly used for architectural cladding, roofing, and facade systems. In the automotive industry, painted aluminum coils are utilized for body panels and trim components. They can also be employed in manufacturing consumer goods, appliances, and other products where a lightweight, durable, and aesthetically pleasing material is required.

application of painted aluminum coil

Proper storage of painted aluminum coil is essential to maintain its quality and protect it from potential damage. Here are some best practices to consider when storing coated aluminum coil:

Dry and Controlled Environment: Store the coated aluminum coil in a dry and controlled environment to prevent moisture from coming into contact with the coils. Moisture can cause corrosion or damage to the paint coating. Ideally, the storage area should have a stable temperature and humidity level.

packaged painted aluminum coil

Protection from UV Exposure: Direct exposure to sunlight or ultraviolet (UV) radiation can degrade the paint coating over time. It is advisable to store the painted aluminum coil in an area that is shielded from direct sunlight or cover it with opaque materials or tarps to prevent UV exposure.

Proper Ventilation: Ensure that the storage area has adequate ventilation to prevent the buildup of moisture or condensation. Good air circulation helps maintain a stable environment and reduces the risk of corrosion.

Vertical Storage: Store the painted aluminum coil vertically, preferably on a rack or pallet. This allows for proper support and avoids excessive bending or deformation of the coils. It also helps prevent any contact or scratching between the coils, minimizing the potential for damage.

Protect Against Contamination: Keep the painted aluminum coil away from chemicals, dust, dirt, and other contaminants that could potentially damage the paint coating. If necessary, cover the coils with protective sheets or plastic wrap to shield them from dust or debris.

Handling with Care: When moving or handling the painted aluminum coil, exercise caution to avoid scratching or damaging the paint coating. Use appropriate lifting equipment or methods to prevent excessive bending or stress on the coils.

Regular Inspection: Periodically inspect the stored painted aluminum coil to check for any signs of damage or deterioration. Look for any corrosion, peeling, blistering, or other issues with the paint coating. Promptly address any identified issues to prevent further damage.

Find durable and reliable 4x10 aluminum sheets for your needs. Explore our wide selection and order today.

Aluminum honeycomb panels are a type of composite material inspired by the hexagonal honeycomb structure found in nature. These panels are renowned for their lightweight, high strength, and versatility, making them a popular choice in various industries, from construction to aerospace.

Aluminum foil for hookah is commonly used for preparing and using a hookah, also known as a shisha or water pipe. It serves a specific purpose in the preparation of the hookah, particularly in the placement and management of the charcoal and tobacco.

Honeycomb aluminum foil, also known as aluminum honeycomb core, is a type of lightweight core material made from two layers of aluminum foil that are bonded together in a way that creates a series of hexagonal cells, much like a honeycomb.

Aluminum foil containers made of aluminum foil can be processed into various shapes, common alloys are 8011, 3003, 3004, 5052 aluminum foil.

6082 aluminium strip can usually be heat treated for higher strength, but relatively low ductility.6082 aluminum alloy is one of the alloy models of...

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip