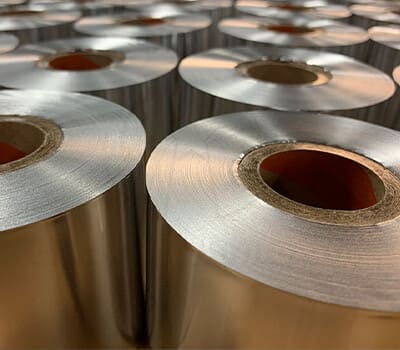

1100 Aluminum Coil is the alloy with the highest commercial purity of all aluminum grades, with an aluminum content (mass fraction) of 99.00%. Its strength is relatively low, and it has excellent ductility, formability, weldability, and corrosion resistance.

1100 Aluminum Coil is the alloy with the highest commercial purity of all aluminum grades, with an aluminium content (mass fraction) of 99.00%. Its strength is relatively low, and it has excellent ductility, formability, weldability, and corrosion resistance. This grade is best suited for welding, brazing, and soldering, but has poor machinability.

1100 aluminum coil suppliers near me

The surface is beautiful, without obvious defects, the surface of the coil is smooth, without edges and corners, and oil spots, but the 1100 aluminum coil cannot be strengthened by heat treatment. Tensile strength ranges from 14 to 24 KSI. Uses include deep drawing, spinning, sheet metal working, decorative and architectural applications, air ducts, nameplates, fan blades, and more.

Our products have been sold to many countries around the world, and 1100 aluminium has excellent finishing capabilities, making it an excellent choice for decorative purposes.

Surface: Powder Coated, Anodized Polished, Mirror Finished, Diamond, Tread, Brushed, Wood Grain, Stucco Embossed

Package: Cover with a layer of plastic film and cardboard, pack on a wooden pallet, tie with iron tape, and put into the container.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Al |

| 1100 | Si+Fe:0.95 | 0.05-0.2 | ≤0.05 | – | – | ≤0.1 | – | 99.00 | |

From: wikipedia

| Tensile Strength(Mpa) | ≥95(110-136) |

| yield strength(Mpa) | ≥50 |

| EL(%) | (3-5)% |

| Density(g/cm³) | 2.68 |

| Alloy Temper |

Specified | Tensile strength |

Yield strength |

Elongation |

| Thickness(in.) | (ksi) | (ksi) | (%) | |

| 1100-O | 0.006-0.019 | 11.0-15.5 | Min3.5 | Min15 |

| 0.020-0.031 | Min20 | |||

| 0.032-0.050 | Min25 | |||

| 0.051-0.249 | Min30 | |||

| 0.250-3.000 | Min28 | |||

| 1100-H12/

1100-H22 |

0.017-0.019 | 14.0-19.0 | Min11.0 | Min3 |

| 0.020-0.031 | Min4 | |||

| 0.032-0.050 | Min6 | |||

| 0.051-0.113 | Min8 | |||

| 0.114-0.499 | Min9 | |||

| 0.500-2.000 | Min12 | |||

| 1100-H14/

1100-H24 |

0.009-0.012 | 16.0-21.0 | Min14.0 | Min1 |

| 0.013-0.019 | Min2 | |||

| 0.020-0.031 | Min3 | |||

| 0.032-0.050 | Min4 | |||

| 0.051-0.113 | Min5 | |||

| 0.114-0.499 | Min6 | |||

| 0.500-1.000 | Min10 | |||

| 1100-H16/

1100-H26 |

0.006-0.019 | 19.0-24.0 | Min17.0 | Min1 |

| 0.020-0.031 | Min2 | |||

| 0.032-0.050 | Min3 | |||

| 0.051-0.162 | Min4 | |||

| 1100-H18/

1100-H28 |

0.006-0.019 | Min22.0 | – | Min1 |

| 0.020-0.031 | Min2 | |||

| 0.032-0.050 | Min3 | |||

| 0.051-0.128 | Min4 | |||

| 1100-H112 | 0.025-0.499 | Min13.0 | Min7.0 | Min9 |

| 0.500-2.000 | Min12.0 | Min5.0 | Min14 | |

| 2.001-3.000 | Min11.5 | Min4.0 | Min20 |

Low-strength aluminum alloys have excellent corrosion resistance and satisfactory anodizing and conversion coating finishing properties. In terms of processing performance, it is unmatched by any other commercial aluminum alloy. Easy to solder, braze and braze. Poor workability, often “tacky”. Not heat treatable.

Non-heat treatable 1100 alloy

Generally used for utensils, heat sinks, bottle caps, printed boards, building materials, heat exchanger parts, and also as deep-drawing products. Widely used in various fields from cookware to industrial equipment.

For those materials that require good formability, high corrosion resistance, and low strength, such as food and chemical handling and storage equipment, sheet metal products, hollow hardware for machining rotating products, welded key combinations, reflectors, nameplates, etc.

From 1100 Aluminium Coil China Supplier Huawei Aluminum

5052 Aluminum Coil is an alloy composed of 2.5% magnesium and 0.25% chromium and is one of the most promising anti-rust aluminum materials

3003 aluminum sheet is an alloy with very good corrosion resistance and moderate strength, the reason this metal is widely used is because it is affordable and strong.

The 3003 aluminium strip is made of 3003 aluminium alloy. The 3 series aluminum alloy is also called an aluminum-manganese alloy.

6061 aluminum sheet is an al-si-mg alloy that has been strengthened by precipitation hardening. 6061 aluminum has a high strength-to-weight ratio, above-average corrosion resistance, good machinability, and is well suited for welding.

Huawei Aluminum is your reliable partner for 0.5mm aluminum coils, and we are committed to meeting your aluminum needs with a wide range of alloy models and specifications.

3105 Aluminum Sheet is adding some other elements on the basis of pure aluminum, such as cu, mg, si, mn, etc., the purpose is to improve the strength of aluminum alloy

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

2000x3000mm aluminum sheet Price and transport

Our required qty: Aluminium Sheet in coil (620mm X 1.20mm) Qty: 200 MT. Can you give me the number of contact urgently. Thanks Matiur Rahman Director of Technical Sales dept.

Bonjour ; Nous sommes une compagnie de spectacle de rue " compagnie carabosse " nous travaillons avec la flamme . nous sommes à la recherche de tôle reflecteur en aluminium pour pouvoir crée un nouvelle objet à base d'un fil métal enflammé liquide éthanol d' une hauteur environ 1 m . Quels produits avez vous à nous proposez ? Cordialement Fabrice

Hello, I am interested in 3*1500*3500 mm 5754 H111 Checkered Aluminium Plate - Diamond Shape Powermaster Ltd. Moscow, Volokolamskoe shosse 1, str. 1, of. 19, Moscow, 125080

Buenos días, Me interesaría saber el costo de Paneles de nido de abeja de aluminio para usar como refuerzo interior de bandejas, estantes , mesadas que realizamos en acero inoxidable AISI 304. De espesor del panel de 10 y 20 mm, con la piel superior e inferior de aluminio espesor 0.8 mm liso o cepillado o solo el núcleo del nido de abeja de aluminio; con tamaño de celda de 10 o 15 mm ( o estándar ) . tamaño de las planchas de 1500 x 3000 mm o la lo que recomiende para el uso que le quiero dar. Desde ya muchas gracias