The 3003 aluminium strip is made of 3003 aluminium alloy. The 3 series aluminum alloy is also called an aluminum-manganese alloy.

3003 aluminium strip is made of 3003 aluminium alloy.

The 3 series aluminum alloy is also called an aluminum-manganese alloy. But not heat treatment, only cold working.

The strength of 3003 aluminum is about 10% higher than that of 1100 aluminium, and it has good formability, weldability, and corrosion resistance.

3003 Aluminium strip

The raw materials of the aluminium strip are pure aluminum or aluminium alloy cast-rolled aluminum coils and hot-rolled aluminium coils, which are rolled into thin aluminum coils of different thicknesses and widths by a cold rolling mill, and then longitudinally cut into aluminum coils of different widths by a slitting machine according to the application. bring.

Commonly used aluminium strip series are 1000, 3000, 5000 and 8000

The most commonly used ones should belong to the all-soft series because the O state is easier to stretch and bend.

| Silicon(Si) | Iron(Fe) | Copper(Cu) | Manganese(Mn) | Magnesium(Mg) | Chromium(Cr) | Nickel(Ni) | Zinc(Zn) | Titanium(Ti) | Others(Each) | Total | Aluminum(Min) |

| 0.6 | 0.7 | 0.05-0.2 | 1.0-1.50 | – | – | – | 0.10 | – | 0.05 | 0.15 | Remainder |

From: wikipedia

| Property | Value |

| Elastic modulus | 69.5 – 70GPa |

| Plane-Strain Fracture Toughnes | 22 – 35MPa·√m |

| Poisson’s ratio | 0.33[-] |

| Shear modulus | 25 – 26GPa |

| Tensile strength | 180MPa |

| Yield strength | 160MPa |

| Property | Value |

| Bending angle(180°) | 1 °/t |

| Bending angle(90°) | 0.5 °/t |

| Elastic modulus | 69 GPa |

| Elongation A50 | 4 % |

| Hardness, HBW | 37 – 45 [-] |

| Shear modulus | 26 GPa |

| Tensile strength | 120 – 185 MPa |

| Yield strength | 80 MPa |

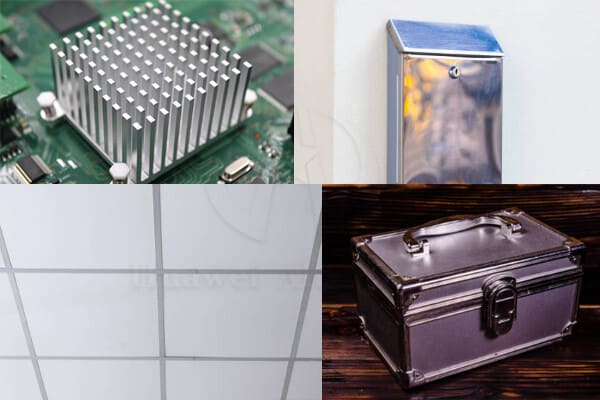

Such as kitchenware, food and chemical products processing and storage devices, tanks and tanks for transporting liquid products, various pressure vessels and pipes processed with thin plates, general utensils, heat sinks, cosmetic plates, photocopier rollers, and ship materials.

Mainly used for low-load parts that require high plasticity and good weldability, working in liquid or gas medium, such as mailboxes, gasoline or lubricating oil conduits, various liquid containers and other small-load parts made by deep drawing: wire rod Used to make rivets.

Application of 3003 aluminium strip

3003 aluminum strip can be used as an insulating glass profile, which is a series of metal materials, which finally stand out after comparing with each other.

Its quality is directly related to the use effect, durability, and thermal insulation function of insulating glass.

The main function is to make two or more pieces of glass in the insulating glass evenly separated and effectively supported.

Power battery housing

At present, aluminum power battery shells for electric vehicles generally use 3003-O or 3003-H14 aluminium alloys.

This material is easy to form, has high-temperature corrosion resistance, good heat transfer, and electrical conductivity.

The aluminum power battery shell (except the shell cover) of 3003 aluminum alloy can be drawn and formed at one time.

Compared with the stainless steel shell, the welding process of the bottom of the box can be omitted.

1. The aluminium strip should be rolled tightly, no loose layer is allowed; no joints are allowed in the coil; the edge of the aluminum strip should be cut neatly, without cracks and burrs, the stacking fault should not be greater than 3mm, the tower shape should not be greater than 20mm, and the coil core must be smaller than The width of the aluminum strip shall not have aluminum plates protruding at both ends;

2. The aluminum coils should be stacked in a flat cylindrical shape, the outer opening of each aluminum coil should be on the same vertical line, and the weight of each box should not exceed 5 tons. Single-layer packing box for flat transportation;

3. Each box of aluminum should have a packing list, including the serial number, tensile strength, elongation, net weight and gross weight of each roll of aluminum;

4. Each roll of aluminum should have a certificate of conformity, and indicate the inspection index, weight, etc.

Package

When transporting aluminum materials, do not throw, violently impact, spray oil and be contaminated by chemicals.

Transportation

1. Do not be hit or thrown during transportation;

2. Aluminum materials should be stored in a well-ventilated place, away from heat sources, oil stains and chemicals, and should not be damp, and should not be stored outdoors;

3. Aluminum strips should be used as soon as possible;

4. Please do not open aluminum materials that are not in use temporarily. For aluminum that has been opened but not used, it should be sealed as soon as possible, and a desiccant should be placed in the package.

Aluminum Sheet Store

3004 Aluminum Sheet is a medium-strength aluminum alloy with manganese and magnesium as the main alloying elements. Its strength is higher than 3003 Aluminum Sheet, but the ductility is lower.

1085 high reflectivity mirror plate is a specialized form of aluminum sheet characterized by its exceptionally high reflectivity and smooth, mirror-like surface finish.

0.75 aluminum sheet refers to an aluminum sheet with a thickness of 0.75 inches, also known as 0.75" aluminum sheet;

5005 aluminum coil refers to the 5005 aluminum plate after being cast and rolled and then processed into a coil shape by drawing and bending,

Explore the unique properties, manufacturing processes, and wide-ranging applications of 1060 aluminum foil. Learn why this high-purity alloy is essential in packaging, electronics, HVAC, and more.

5×10 aluminum sheet is a common specification of aluminum sheet produced by aluminum sheet manufacturers,it is 5 feet wide and 10 feet long.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Our required qty: Aluminium Sheet in coil (620mm X 1.20mm) Qty: 200 MT. Can you give me the number of contact urgently. Thanks Matiur Rahman Director of Technical Sales dept.

Bonjour ; Nous sommes une compagnie de spectacle de rue " compagnie carabosse " nous travaillons avec la flamme . nous sommes à la recherche de tôle reflecteur en aluminium pour pouvoir crée un nouvelle objet à base d'un fil métal enflammé liquide éthanol d' une hauteur environ 1 m . Quels produits avez vous à nous proposez ? Cordialement Fabrice

Hello, I am interested in 3*1500*3500 mm 5754 H111 Checkered Aluminium Plate - Diamond Shape Powermaster Ltd. Moscow, Volokolamskoe shosse 1, str. 1, of. 19, Moscow, 125080

Buenos días, Me interesaría saber el costo de Paneles de nido de abeja de aluminio para usar como refuerzo interior de bandejas, estantes , mesadas que realizamos en acero inoxidable AISI 304. De espesor del panel de 10 y 20 mm, con la piel superior e inferior de aluminio espesor 0.8 mm liso o cepillado o solo el núcleo del nido de abeja de aluminio; con tamaño de celda de 10 o 15 mm ( o estándar ) . tamaño de las planchas de 1500 x 3000 mm o la lo que recomiende para el uso que le quiero dar. Desde ya muchas gracias

Proszę o ofertę na blachę aluminiową grubość 20 mm, w gatunku 1060. 8000 kg