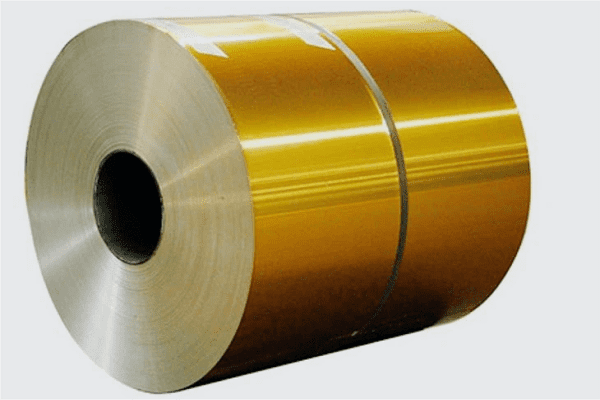

Export of coated aluminum foil raw materials, factory supply with the best price, high quality, corrosion resistance and long service life

Coated aluminum foil is aluminum foil coated with certain materials to enhance its performance or provide additional functions. It is a composite aluminum foil. Aluminum foil coatings are typically applied to one or both sides of aluminum foil and can be used for a variety of purposes.

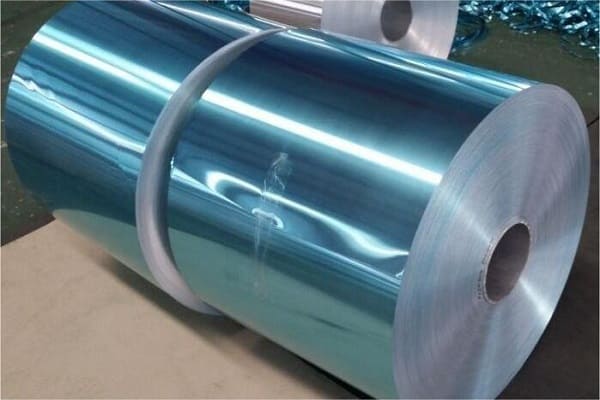

coated aluminum foil

Coated aluminum foil is classified into two categories in terms of application: 1. Industrial use 2. Food use

| Common industrial uses | building materials decoration, ventilation ducts in HVAC projects, thermal insulation materials (phenolic boards), etc. |

| Coated lunch boxes for food | Coated lunch boxes for food, coated aluminum foil food packaging materials, etc. |

| Product | Temper | Thickness | Width |

| Coated aluminium foil | Hard | 0.015-0.3mm | 1300mm(max) |

| O | 0.04-0.3mm | 1300mm(max) |

Coated aluminum foil for thermal insulation: Coated aluminum foil has a heat-resistant coating that helps reflect and block heat, making it useful for building insulation, packaging, or as a barrier in automotive applications.

Aluminum foil coating for packaging: Some aluminum foils are coated to increase the foil’s resistance to moisture, oxygen or other environmental factors, making them suitable for packaging food, pharmaceuticals and other sensitive products.

Aluminum coated foil is used in laminates: Aluminum foil is coated and then laminated with other materials such as paper, plastic or fabric to form composite materials with unique properties.

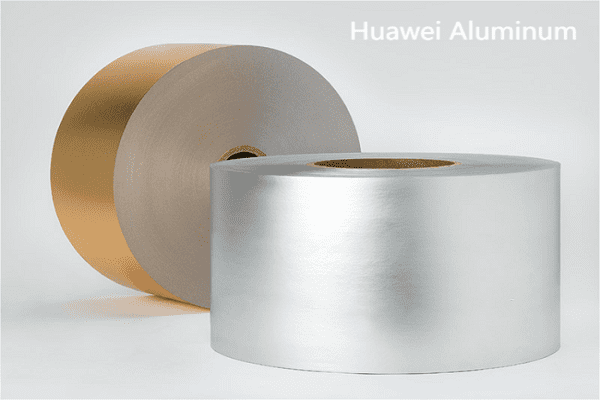

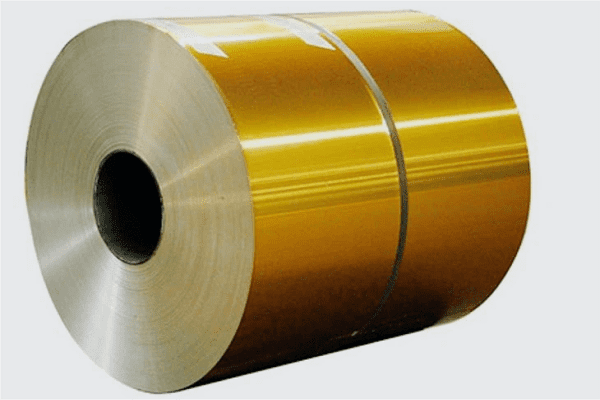

color coated aluminum foil

Aluminum foil coating for decoration: Coated aluminum foil can be used for decorative purposes in crafts, art projects, and in gift or specialty product packaging.

Color coated aluminum foil for adhesive backing: Coated aluminum foil with adhesive backing can be used in various applications such as tapes, labels and stickers.

HWALU can provide 1000-8000 series of aluminum alloy raw materials and produce coated aluminum foil in various specifications.

| Alloy Series | Grade |

| 1xxx serires | 1050 1060 1070 1100 1235 |

| 3xxx serires | 3003 3004 |

| 5xxx serires | 5052 5082 5083 5086 |

| 6xxx serires | 6061 6063 6082 |

| 8xxx serires | 8011 8021 8089 |

The production process for aluminum coated foil can vary depending on the type of coating required and the end use. A general process is as follows.

Uncoiling → Pretreatment (First pickling → Second pickling → Third pickling → Water washing → First drying → Passivation treatment → Second drying) → Roller coating → Third Drying→Winding

Huawei Aluminum will roll the processed coated aluminum foil to the required roll size, or cut it into the required sheet size to meet customer needs.

The passivation treatment of aluminum foil involves three processing methods:

1. (Industrial use) Hexavalent chromium,

2. (for food) trivalent chromium,

3. Silane treatment.

1. Oily material processing 2. Water-based material processing

| Oily materials | E PVDF HDPE epoxy varnish, etc. |

| Water-based materials | Hydrophilic layer |

1. For polyester, the single coating thickness of the front topcoat is 16-18 microns. The double coating is primer and topcoat 10+15 microns. Apply it twice. Polyester is 8-10 microns, and the back paint is more commonly used.

2. Fluorocarbon is double-coated with 25 micron primer and topcoat of 10+15 μm. There are other common coating thicknesses: 35 micron (10+15+10 micron). The top layer is varnish, fluorocarbon. The primer is polyurethane and the topcoat is fluorocarbon.

3. Back paint is based on customer requirements: polyester and epoxy varnish, off-white or transparent

aluminium foil coated

Coated aluminium foil has a variety of properties and advantages, and the properties will vary depending on the coating structure.

1. Thermal insulation: Coated alloy aluminum foil can reflect and block heat, making it an effective thermal insulation in buildings, HVAC systems and automotive applications.

2. Moisture-proof: Coated foil can provide a moisture-proof layer, making it suitable for packaging food, pharmaceuticals and other products that need to be protected from moisture and moisture.

3. Corrosion resistance: Some coatings enhance the corrosion resistance and chemical exposure resistance of aluminum foil, increasing its service life.

4. UV resistance: Aluminum foil coating can make the foil resistant to ultraviolet (UV) radiation, which is beneficial for outdoor and long-term exposure applications.

5. Strong adhesion: The coating can enhance the adhesion of inks, adhesives and other materials to the foil surface.

6. Easy to print: The coating can make the foil surface suitable for high-quality printing, allowing for branding and label customization.

7. Lightweight and Durable: The aluminum foil itself is lightweight but strong, and the coating adds specific functionality without significantly increasing weight.

The density of aluminum alloy coated aluminium foil is close to that of pure aluminum alloy, about 2.7×10³kg/m³ (2.7g/cm³)

Learn more: aluminum alloy density

Same as 1050 aluminum sheet, 1060 aluminum sheet also belongs to 1 series pure aluminum sheet,Commonly used in lithium battery soft connection, bus bar, road sign, charging pile, aluminum gasket, billboard building exterior wall decoration,and so on.

Aluminum circle for cookware bottoms are normally called "aluminum disc" or "aluminum disk." these are circular portions of aluminum which might be used because the base or backside of various forms of cookware, which includes pots, pans, and strain cookers.

040 Aluminum Sheet is a type of aluminum sheet that has a thickness of 0.04 inches, which is equivalent to 1.016 millimeters. It is a thin and lightweight material

Our 3003 Aluminum foil products have been exported to Australia, Morocco, Syria, Kuwait, Turkey, Saudi Arabia, UAE, Iraq, Jordan, Germany, Poland, Spain, Brazil, etc. We sincerely welcome you to visit our factory.

3104 aluminum sheet has suitable elongation, good corrosion resistance and good processability. Therefore, we can smelt it into alloys of different hardness according to different application requirements.

5086 aluminum sheet is a high-strength, corrosion-resistant al-mg alloy, widely used in aerospace, transportation, architectural decoration and other fields.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip