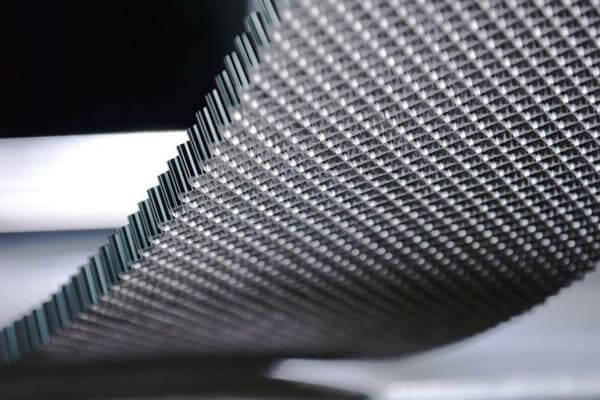

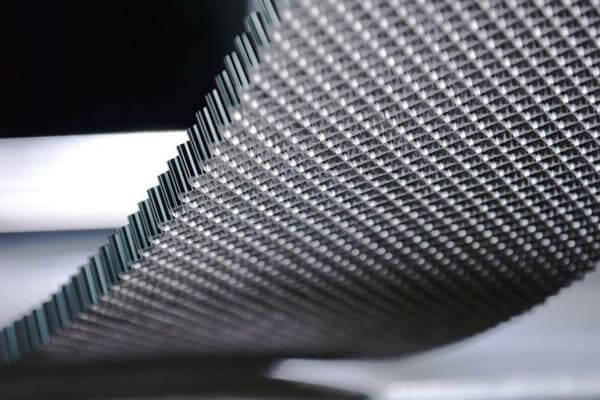

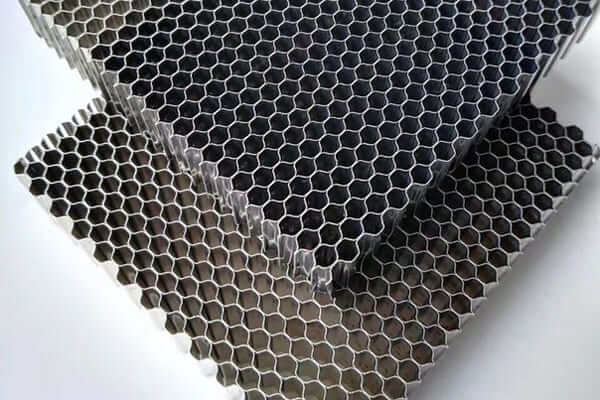

Honeycomb aluminum foil, also known as aluminum honeycomb core, is a type of lightweight core material made from two layers of aluminum foil that are bonded together in a way that creates a series of hexagonal cells, much like a honeycomb.

Honeycomb aluminum foil, also known as aluminum honeycomb core, is a type of lightweight core material made from two layers of aluminum foil that are bonded together in a way that creates a series of hexagonal cells, much like a honeycomb. These cells are then expanded into a core material that is lightweight, strong, and rigid.

Honeycomb aluminum foil

Honeycomb aluminum foil is commonly used in a variety of applications, such as aerospace and aviation industries, marine and naval structures, as well as in construction and architecture. The lightweight and high strength properties of honeycomb aluminum make it an ideal material for sandwich panels, which are made by bonding two outer layers of material (such as fiberglass or carbon fiber) to a honeycomb aluminum core.

Honeycomb aluminum foil also has excellent sound and vibration dampening properties, making it useful in applications such as speaker grills, acoustic panels, and industrial enclosures.

Executable standards for honeycomb aluminum foil: national standard, American standard, European standard, Russian standard, Chinese standard, etc.

3003 h18 aluminum foil jumbo roll

| Alloy | 3003/3004/3104/5052 |

| Temper | H18/H19 |

| Thickness | 20-100um |

| Width | 20-1500mm, Common 914/1020mm, max 1500mm |

| Length | Customize |

| Honeycomb side length | 5/6/8/10/12 mm |

| Surface technology | Pickling+water washing+silane passivation+epoxy varnish |

Aluminum foil for honeycomb core is a type of aluminum foil that is used as a raw material to manufacture honeycomb cores.

The common alloy grades are 3003/3004/3104/5052, the mechanical and mechanical properties of 3004 and 3104 are basically the same, usually 3004 can be used instead of 3104 alloy aluminum;

The biggest difference between honeycomb core used aluminum foil and conventional aluminum foil is the surface treatment;

5052 aluminum honeycomb core

1. High board surface flatness – good board shape

Equipped with a shape controller to monitor the shape in real time; the follow-up straightening process, the second correction of the shape; to ensure that the aluminum foil shape is good, the layout is high, and the shape accuracy is good!

2. High strength – not easy to deform after processing

3003-h18 aluminum foil is used as the aluminum foil base material for the honeycomb core, which has high strength, the finished product is not easy to deform, the end surface is flat, the edge is free of burrs, and the board surface is flat after bonding and laminating;

3. The surface of the aluminum foil is degreased and clean – the glue is not easy to fall off

Special degreasing equipment and passivation process ensure that the surface of the aluminum foil is free of oil, the adhesive is firm, not easy to fall off, and has a long service life;

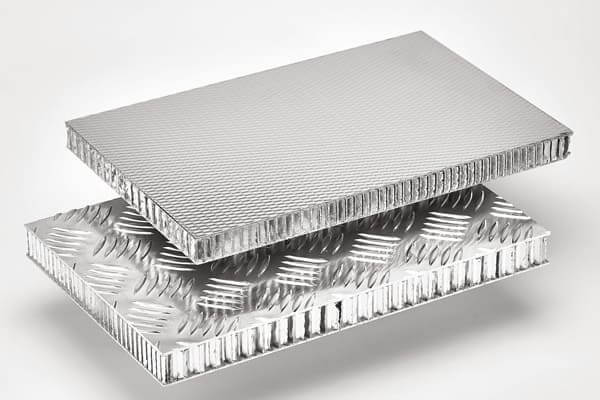

The upper and lower bottom plates and panels of aluminum honeycomb panels are made of aluminum alloy plates, with a thick and light honeycomb core sandwiched in the middle (the aluminum honeycomb core is made of aluminum foil through complicated processes;), the panel and the sandwich core are bonded The agent is cemented into a monolithic rigid structure.

Panel surface treatment can be fluorocarbon, roller coating, thermal transfer printing, wire drawing, oxidation; aluminum honeycomb panels can also be pasted and compounded with fireproof boards, stone materials, and ceramics.

Aluminum honeycomb panels have the characteristics of light weight, high strength, sound insulation, heat insulation, waterproof, moisture-proof, and heat preservation;

Honeycomb aluminum panel for ceiling

Honeycomb aluminum foil

Derived from dyne, it is the unit of force, expressed as dyne/cm, expressing the size of the surface tension coefficient, defined as the force of mutual traction per unit length between two adjacent parts of the liquid surface, 1dyn/cm=1mN /m.

When the surface tension coefficient is large, the liquid can wet the solid surface better, that is, the surface dyne value of the material is high.

The wettability of solid surfaces is usually evaluated by surface free energy, contact angle, and dyne value. Relatively speaking, the contact angle measuring instrument will be more accurate, followed by the surface free energy, and the dyne pen can quickly and roughly judge.

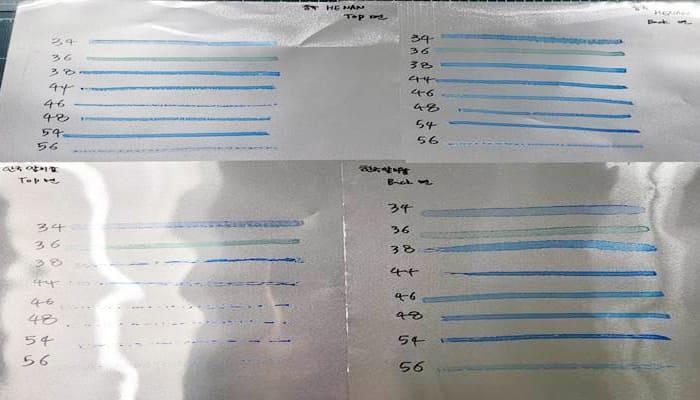

Dyne Pen Test

Dyne pen specifications generally range from 30-70, and our common ones are 36/38/40/42/44. These numbers represent that the surface tension coefficient of the material is so large

dyne pen test

How to use Dyne pen:

Choose a pen with an estimated dyne size.

Draw a straight line (5-10cm) evenly on the surface of the measured object with the Dyne pen.

After 2~3 seconds, observe whether the handwriting shrinks and condenses into water droplets. If there are shrinkage drops, change to a dyne pen with a lower value and draw a straight line until there is no shrinkage and no droplet points to determine the surface tension value of the object.

If the handwriting is smooth, change to a dyne pen with a higher value and draw again until the handwriting shrinks, then the dyne pen number of the previous value is the dyne value on the surface of the measured object.

Dyne pen result analysis:

If the drawn lines are evenly distributed without any beads, it means that the surface tension of the film is higher than the dyne pen index, and it can be printed in this case.

If the drawn line shrinks slowly, it means that the surface tension of the film is slightly lower than the dyne pen index. In this case, the printing effect is not good.

If the drawn line shrinks immediately and forms bead points, it means that the surface tension of the film is very lower than the dyne pen index. This case cannot be printed.

3003 h14 aluminum coil refers to h14 tempered 3003 aluminum coil.And H14 tempering usually means getting 1/2 the strength with the hardness.

5052 Aluminum Coil is an alloy composed of 2.5% magnesium and 0.25% chromium and is one of the most promising anti-rust aluminum materials

We use the pure aluminum ingots to manufacture 5mm aluminum sheets. They come in various widths and tempers. They are not only suitable for marine grade, but also for automobile manufacturing, pressure vessels, including water tanks, oil tanks, and the maximum width we can produce is 3000mm.

5005 aluminum sheet is a medium-strength aluminum alloy plate, which can reach medium and high strength by cold working, and it has good formability

Aluminum foil is one of the components of power capacitor equipment. The addition of aluminum foil material can not only improve the quality of the capacitor, but also increase the voltage resistance of the capacitor while ensuring the performance and life of the capacitor.

1/8 aluminum sheet is often used in the manufacture of tanks and ships because of its strong hardness and corrosion resistance, etc.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

I need a quotation for 3000 series aluminum sheets/coils (3104 H19) for tuna can production, food-grade finish, delivery to Mazatlán, Mexico.

I am planning a business trip to China and I am very interested in your aluminium 8011 products for food container production. I would like to visit your factory during my stay in china: See your production lines (foil rolling, annealing, slitting, packing). Discuss specifications (8011-O temper, thickness 0.05–0.08 mm, jumbo roll). Review your quality certificates and export experience. Could you please let me know: Your available dates for a visit The location of your factory If you can provide an invitation letter for my business visa (M visa). Thank you for your kind support. Looking forward to your reply. Best regard: LOUNIS MUSTAPHA company name:TOP BARQUETTE SELECT [email protected] what's up:213 770 91 69 43

Merhaba ; Burak ÜNAL ben. Antalya ' da Ambalaj ve Temizlik ürünleri tedarik eden bir firmanın yetkilisiyim. Ayrıca P.E Streç aktarım işi yapmaktayım. Makinalarımızı 9 ve 10 micron alüminyum folyo aktarımına uyacak şekilde revize edeceğiz. Sizden istediğim, 9 veya 10 micron olacak şekilde 35 cm ve 45 cm jumbo folyolar için fiyat, termin ve şu bilgileri istiyorum ; 35 cm jumbo folyonun ortalama ağırlığı. 45 cm jumbo folyonun ortalama ağırlığı. Deneme olacağı için bu 2 ölçüde minimum sipariş tonajımız ne kadar olması gereklidir. İyi çalışmalar.

We are A Commercial Lighting 's parts and accessories Manufacturer in egypt below is our current requirements for production process from aluminum coil (Alloy 1050 temper O thickness 0.3 mm width 25cm=10tons width 29.5cm=6tons width 33.5cm=5tons width 37 cm=5tons kindly send us your best quotation ASAP according to our company below details: Below is our company details : Full legal company name: Focused ligth for industrial investment ., Co address: Plot no 8 - extension of 4th industrial - zone sadat - minofia - egypt Telephone number Ahmed nseem +201016644789 & +201010879400 Eng Moh El shrief : Mob : +2 01016644789 Tax ID number : 699-483-174

I am writing to inquire about the products that your company offers. I am particularly interested in the product listed below: *Aluminum Coil QTY-20 Units Could you please provide me with more information on these products, including pricing, availability, and any additional details that may be relevant? and also quote your ordinary unit price for supplying these product, together with your discount price for the volume purchase of full truck load. Note: Additionally to the above, our standard Payment Terms:Net 15days to 30 days from the date of supply with the supplier's Invoice.